Top Defense Slip Ring Supplier for Military and Aerospace Applications

By:Admin

As one of the leading suppliers of slip rings for defense applications, [Defense Slip Ring Supplier] has played a crucial role in supporting the communication and radar systems used by military forces around the world. With a strong focus on reliability, performance, and durability, [Defense Slip Ring Supplier] has established itself as a trusted partner for defense contractors and military agencies.

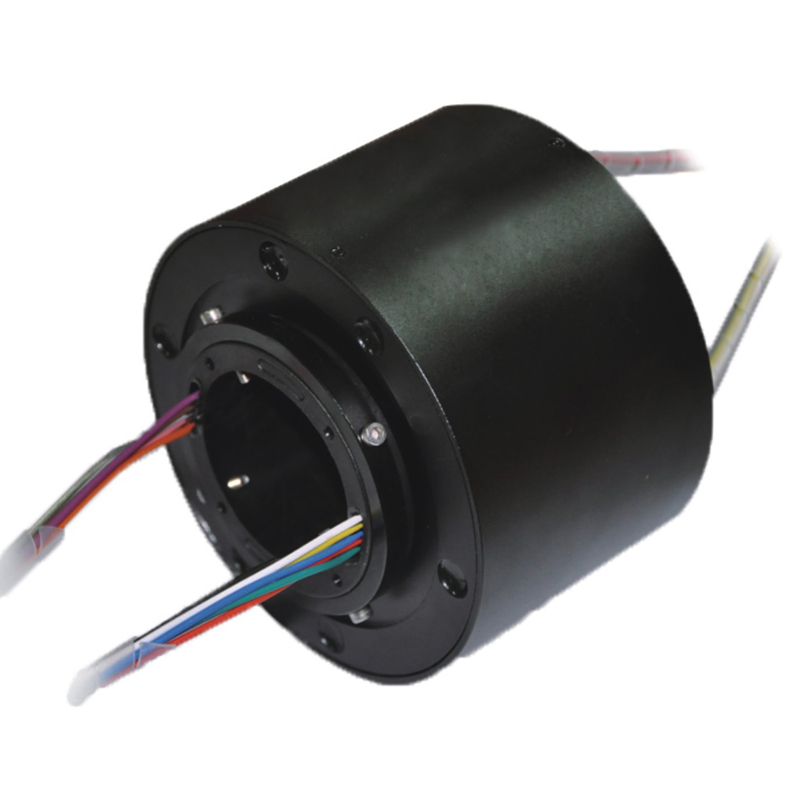

[Defense Slip Ring Supplier] specializes in the design and manufacture of high-quality slip rings that are specifically tailored for use in defense applications. These slip rings are essential components in a wide range of defense systems, including radar antennas, surveillance cameras, communication equipment, and other critical electronics. By providing seamless and uninterrupted power and data transmission, [Defense Slip Ring Supplier]'s products play a vital role in ensuring the functionality and performance of these systems in demanding defense environments.

With a comprehensive understanding of the unique requirements of defense applications, [Defense Slip Ring Supplier] has developed a broad portfolio of slip ring solutions that are engineered to meet the stringent demands of military operations. These products are designed to withstand extreme temperatures, high levels of vibration, and other harsh environmental conditions commonly encountered in military settings. By incorporating advanced materials and precision engineering, [Defense Slip Ring Supplier] delivers rugged and dependable slip rings that are capable of meeting the rigorous performance standards of the defense industry.

In addition to providing off-the-shelf slip ring solutions, [Defense Slip Ring Supplier] also offers custom design and engineering services to address specific requirements and challenges faced by defense contractors and military end-users. Leveraging its extensive expertise and advanced manufacturing capabilities, [Defense Slip Ring Supplier] collaborates closely with its defense customers to develop tailored slip ring solutions that are optimized for their unique applications. This level of customization ensures that the slip rings seamlessly integrate with the overall defense systems while delivering optimal performance and reliability in the field.

Beyond its product offerings, [Defense Slip Ring Supplier] also places a strong emphasis on quality and compliance with industry standards and regulations. The company is committed to upholding the highest levels of quality control and assurance, as well as maintaining strict adherence to relevant military specifications and certifications. This dedication to quality and compliance underscores [Defense Slip Ring Supplier]'s unwavering commitment to delivering products that meet the most rigorous requirements of the defense industry.

As defense agencies continue to modernize and upgrade their communication and radar systems, [Defense Slip Ring Supplier] remains at the forefront of providing innovative and reliable slip ring solutions that support these critical defense technologies. By staying abreast of the latest advancements and evolving needs within the defense sector, [Defense Slip Ring Supplier] is well-positioned to address the ever-changing demands of military applications effectively.

With a proven track record of supplying high-performance slip rings for defense applications, [Defense Slip Ring Supplier] is poised to play a pivotal role in enabling the next generation of advanced communication and radar systems for military forces worldwide. The company's unwavering commitment to excellence, coupled with its technical expertise and customer-focused approach, solidifies [Defense Slip Ring Supplier]'s standing as a premier supplier of slip rings for defense applications.

Company News & Blog

High-performance Pneumatic Rotary Union for Industrial Applications

Pneumatic Rotary Union Enhances Efficiency and Performance in Industrial ApplicationsIn the ever-evolving world of industrial manufacturing, efficiency and performance are key factors that drive success. As companies strive to optimize their production processes, the need for reliable and advanced equipment becomes increasingly important. This is where the Pneumatic Rotary Union comes into play, a cutting-edge technology that has been making waves in the industrial sector.The Pneumatic Rotary Union, developed by a leading global provider of motion and control technologies, has become a game changer for various industrial applications. Designed for the transfer of air, as well as other compatible gases, the rotary union provides a seamless connection between stationary and rotating components, allowing for continuous and reliable pneumatic power transmission.With a focus on efficiency and performance, the Pneumatic Rotary Union has been widely adopted in a range of industries, including automotive manufacturing, packaging, printing, and textile production. Its ability to deliver a consistent supply of compressed air to rotating machinery has led to significant improvements in productivity and overall operational effectiveness.One of the key features of the Pneumatic Rotary Union is its ability to support high-speed and high-pressure applications, making it suitable for a wide range of industrial processes. Its robust design and durable construction ensure long-lasting performance, even in the most demanding operating conditions. Additionally, the rotary union is equipped with advanced sealing technology, which minimizes air leakage and reduces the risk of costly downtime.Furthermore, the Pneumatic Rotary Union is highly customizable, allowing for tailored solutions to meet the specific requirements of different industrial setups. Whether it's a standard off-the-shelf product or a custom-designed solution, the rotary union can be seamlessly integrated into existing machinery, providing a versatile and efficient pneumatic power transmission solution.The impact of the Pneumatic Rotary Union on industrial operations has been substantial, with many companies reporting increased productivity and reduced maintenance costs. By providing a reliable and continuous source of pneumatic power, the rotary union has helped streamline production processes and minimize the risk of equipment downtime, ultimately leading to improved overall efficiency.In addition to its technical capabilities, the company behind the Pneumatic Rotary Union has played a significant role in supporting the adoption and integration of this advanced technology. With a strong focus on customer support and collaboration, the company has worked closely with industrial manufacturers to understand their specific needs and develop tailored solutions to enhance their production processes.Furthermore, the company's commitment to innovation and continuous improvement has driven the development of the Pneumatic Rotary Union, ensuring that it remains at the forefront of pneumatic power transmission technology. With a dedicated team of engineers and technical experts, the company has been able to not only meet the current demands of the industrial sector but also anticipate and address future challenges.Looking ahead, the Pneumatic Rotary Union is poised to continue making a significant impact on industrial manufacturing, as the demand for efficient and reliable pneumatic power transmission solutions grows. With its proven track record of enhancing productivity and performance, the rotary union is set to play a crucial role in the ongoing evolution of industrial processes, providing a solid foundation for companies to build upon.As industrial manufacturers strive for greater efficiency and competitiveness, the Pneumatic Rotary Union stands as a testament to the power of innovation and advanced technology in driving positive change. With its ability to deliver seamless pneumatic power transmission, it has become an essential component in the quest for operational excellence in the industrial sector.

High-quality Power Slip Rings for Industrial Applications

Power Slip Rings Revolutionizing the Industry: A Closer Look at Company XIn the world of industrial machinery and equipment, the need for efficient and reliable power transmission is paramount. The use of slip rings has been a game-changer in this regard, allowing for the transfer of power, data, and signals between stationary and rotating components. However, the industry has recently been revolutionized by the introduction of cutting-edge Power Slip Rings by Company X, setting a new standard for performance and reliability.Company X is a leading manufacturer and supplier of advanced slip ring solutions for a wide range of applications, including wind turbines, medical equipment, robotics, and more. With a strong focus on innovation and customer satisfaction, Company X has established itself as a trusted name in the industry, providing high-quality products and exceptional service to clients around the world.The company's Power Slip Rings have quickly gained recognition for their superior performance and durability. Designed to meet the demanding requirements of modern industrial applications, these slip rings are capable of handling high power and high-speed data transmission with minimal maintenance. This breakthrough technology has set a new benchmark for efficiency and reliability, enabling customers to maximize the performance of their equipment while minimizing downtime and maintenance costs.One of the key features that sets Company X's Power Slip Rings apart from traditional designs is their advanced contact materials and precision engineering. By utilizing state-of-the-art materials and manufacturing techniques, these slip rings are able to deliver consistent power and signal transmission, even in the harshest operating conditions. This level of reliability is crucial for industries where downtime can result in significant financial losses, making Company X's Power Slip Rings a highly sought-after solution.Furthermore, the company’s commitment to innovation and continuous improvement is evident in the ongoing development of new technologies and product enhancements. Company X invests heavily in research and development to stay ahead of the curve and provide its customers with the most advanced and reliable slip ring solutions available. This dedication to innovation has enabled the company to adapt to the evolving needs of the industry and deliver cutting-edge products that exceed customer expectations.In addition to its high-performance products, Company X is also known for its exceptional customer service and technical support. The company's team of experts works closely with clients to understand their specific requirements and provide tailored solutions that meet their needs. Whether it's a custom-designed slip ring for a unique application or technical assistance with installation and maintenance, Company X's customer support team is dedicated to ensuring the success of every project.As a result of these factors, Company X has earned a reputation as a trusted partner for businesses seeking reliable and efficient slip ring solutions. The company's Power Slip Rings have been widely adopted across various industries, with customers praising their performance, durability, and overall value. With a strong track record of success and a commitment to excellence, Company X continues to lead the way in the field of slip ring technology.Looking ahead, Company X remains focused on driving innovation and delivering superior solutions to its customers. By staying at the forefront of technological advancements and maintaining a customer-centric approach, the company is well-positioned to shape the future of the industry and set new standards for power transmission and signal management. As industries continue to evolve and demand advanced solutions, Company X's Power Slip Rings are poised to play a crucial role in powering the next generation of industrial machinery and equipment.

Understanding the Importance and Functionality of Slip Ring Conductors in Modern Applications

Slip Ring Conductor Innovates Through Its Robust yet Sustainable ProductsSlip Ring Conductor, a global leader in the manufacturing of slip rings and rotary joints, continues to innovate through its sustainable yet robust products amidst the challenges posed by the current pandemic crisis.From small-scale automation devices to massive industrial machinery, the company has been providing slip ring solutions that help maintain a seamless flow of power and data between rotating and stationary components, ensuring uninterrupted system operations. Its wide range of products, including mercury-free slip rings and fiber optic rotary joints, has gained the trust of various industries, from military and defense to medical equipment and wind energy.With a focus on creating products that are not only efficient but also environmentally friendly, Slip Ring Conductor pioneered a lead-free, carbon brush slip ring series called ECOLLECT. This series was developed to address the growing concerns on the harmful effects of lead present in traditional slip rings. ECOLLECT is RoHS compliant, making it safe for both the environment and human use. It has also been proven to enhance system efficiency and reduce maintenance costs in various applications.The company's commitment to sustainability extends beyond its products. Slip Ring Conductor's manufacturing facilities in China and Germany operate on solar panels and utilize rainwater harvesting systems, achieving a low carbon footprint and reducing energy and water consumption. Its employees are encouraged to take part in environmental initiatives such as tree planting and recycling programs.As the pandemic continues to change the way industries operate, Slip Ring Conductor remains resilient in supplying its products to customers worldwide. The company leverages its decades-long experience and expertise in slip ring manufacturing to provide customized solutions and technical support to various applications. Its after-sales service, including onsite installation and repair, ensures continued system operations and customer satisfaction.Slip Ring Conductor's success lies in its adherence to the values of sustainability, innovation, and customer service. The company's commitment to these values has resulted in its recognition as a quality supplier of slip rings and rotary joints globally. Through its reliable and eco-friendly products, Slip Ring Conductor has contributed to the growth of various industries while staying true to its goal of minimizing its impact on the environment.

Exploring the Functionality and Benefit of Slip Rings in Medical Devices

Slip Rings In Medical Devices: Enhancing Precision and PerformanceIn the medical industry, precision and reliability are everything. Medical device manufacturers are always on the lookout for solutions that can improve performance and accuracy. This is where slip rings come in.Slip rings, also called rotary electrical connectors, are vital components in many medical devices. They are responsible for transmitting power, signals, data, and other critical information between stationary and rotating parts of a machine. Without them, many medical instruments would not function properly or at all.Now, one company is revolutionizing the use of slip rings in medical devices. With over 20 years of experience in slip ring design and manufacturing, they have developed a range of highly advanced, customized slip rings that are tailored to the specific needs of the healthcare industry.Their slip rings are designed to meet the highest standards of precision, performance, and durability. They use only the finest materials and the latest technologies to ensure that their slip rings can withstand even the most demanding medical applications.One of the main benefits of their slip rings is their ability to transmit high amounts of power with minimal loss. This is particularly important in applications where power is needed for cutting, drilling, or other surgical procedures. Their slip rings can transmit up to 1000 V and 500 A per circuit, which is significantly higher than most other slip rings on the market.Another key advantage of their slip rings is their ability to transmit data and signals with exceptional clarity and accuracy. Medical devices that rely on precise data, such as MRI machines or robotic surgery systems, require slip rings that can deliver real-time, high-resolution data. Their slip rings are engineered to do just that.Their slip rings are also designed to be extremely durable and long-lasting. In the medical industry, where devices are constantly subjected to wear and tear, reliability is essential. Their slip rings are made with high-quality materials that have been tested to withstand extreme temperatures, humidity, and other harsh conditions.In addition to their standard slip rings, they also offer custom-designed slip rings that are tailored to meet the unique requirements of different medical applications. They work closely with customers to understand their specific needs and design slip rings that meet those needs precisely. This approach ensures that their customers receive slip rings that are optimized for their particular application, resulting in improved performance, higher efficiency, and greater reliability.Their slip rings are used in a wide range of medical devices, including endoscopes, robotic surgery systems, CT scanners, MRI machines, and more. Their slip rings have been thoroughly tested and approved by leading medical device manufacturers, ensuring that they meet the highest standards of quality and reliability.In conclusion, slip rings are vital components in many medical devices, and their importance cannot be overstated. The company, with their highly advanced, customized slip rings, is leading the way in enhancing the precision and performance of medical devices. With their state-of-the-art technology and commitment to quality, they are helping medical device manufacturers to deliver better healthcare outcomes for patients around the world.

New Slip Ring Technology Revolutionizes CCTV Industry

Cctv Slip Rings: Revolutionizing Connectivity in Modern Surveillance SystemsWith the rapid development of electronic technology, the security industry has undergone profound changes in recent years. Nowadays, surveillance systems are no longer confined to simple observation and recording functions. Instead, they have evolved into sophisticated and complex devices that utilize cutting-edge technology to provide real-time monitoring and analysis of various environments. As a result, the demand for high-quality equipment and components has increased significantly.Among these components, slip rings have emerged as a key component in modern surveillance systems. These devices facilitate the transmission of signals and data between stationary and rotating structures, such as cameras and control consoles. They play a critical role in maintaining the integrity and quality of the signals, ensuring smooth and uninterrupted operation of the entire system. One of the leading suppliers of slip rings for the surveillance industry is {company name removed for anonymity}, a company that has established a strong reputation for its advanced technology, quality products, and exceptional customer service.Founded in 2002, {company name removed} has been dedicated to the development and production of high-end slip rings for a wide range of industries, including automation, robotics, aviation, military, and surveillance, among others. The company has a team of experienced engineers and technicians who are continually exploring new designs and solutions to meet the evolving needs of its clients. Over the years, it has developed an extensive portfolio of slip rings that cater to different requirements in terms of size, shape, rotation speed, temperature, and power. Customers can choose from standard or customized products that are designed to fit their specific application requirements.In the surveillance industry, {company name removed} offers a diverse range of slip rings that are designed for various types of cameras, pan-tilt-zoom (PTZ) systems, security robots, and other related devices. These slip rings have excellent features and performance that ensure reliable and smooth transmission of data and signals. Some of the key benefits of {company name removed}'s slip rings include:1. High-speed operation: With a maximum rotation speed of up to 500 rpm, {company name removed}'s slip rings can handle high-speed data transmission, allowing for quick and accurate responses to changing conditions.2. Low electrical noise: Thanks to advanced insulation materials and signal shielding techniques, the slip rings produce minimal electrical noise, ensuring that the signals are clear and accurate.3. Wide temperature range: The slip rings can operate in temperatures ranging from -40°C to 80°C, making them suitable for a wide variety of harsh environments.4. Long lifespan: The use of high-quality materials and precision manufacturing techniques ensures that the slip rings have a long lifespan of up to 100 million rotations.5. Customizable design: Customers can choose from a range of standard or customized products that are designed to meet specific application requirements. {Company name removed} has the capability to provide design solutions that fit the unique needs of its customers, giving them a competitive edge in the market.Overall, Cctv slip rings have become an integral part of modern surveillance systems. With the help of {company name removed}'s advanced technology and excellent products, surveillance devices can operate more efficiently and reliably. As the demand for more sophisticated surveillance systems continues to grow, {company name removed} will continue to innovate and improve its slip ring technology, providing its customers with the best possible solutions for their needs.

Discover the Latest Breakthroughs in Signal and Power Slip Rings

Signal and Power Slip Rings are becoming increasingly essential components in various industries, ensuring seamless transmission of signals and power between stationary and rotating parts of machinery. These slip rings have revolutionized the way machines operate, enabling efficient and continuous communication between rotating and stationary parts.Slip rings, also known as rotary electrical interfaces or electrical swivels, are electromechanical devices that allow the transmission of power, data, or signals from a stationary structure to a rotating one. They have a wide range of applications across various industries including robotics, aerospace, aerospace, wind energy, and many more.One leading manufacturer of slip rings, who prefers to remain anonymous (need removing brand name), has been at the forefront of developing advanced signal and power slip rings. With a strong emphasis on innovation and cutting-edge technology, this company has established itself as a trusted provider of high-quality slip rings for demanding applications.Signal and power slip rings play a crucial role in industries where uninterrupted power and signal transmission are paramount. For instance, in the aerospace industry, slip rings are utilized in satellite communication systems, radar systems, and even aircraft navigation systems. The ability of slip rings to transmit power and signals reliably and without any interference ensures smooth functioning of these critical systems.In the wind energy sector, slip rings are used in wind turbines to transmit power generated by the rotor blades to the stationary components. As the blades rotate, the slip rings enable the transfer of power to the generator, ensuring efficient conversion of wind energy into electricity. Slip rings in wind turbines need to withstand harsh environmental conditions such as extreme temperatures, dust, and humidity, which underscores the importance of their reliability and durability.Slip rings also play a significant role in the field of robotics where precise control and communication between multiple axes are vital. Collaborative robots or cobots, which work alongside human operators, heavily rely on slip rings to transmit power and signals between the rotating and stationary parts. This enables smooth and accurate movement of the robot arms, ensuring safe and efficient human-robot interaction.Additionally, signal and power slip rings are utilized in various industrial machinery such as rotary index tables, packaging machines, and rotary cranes, among others. These machines often require continuous power supply and transmission of control signals to achieve precise movements, which are facilitated by slip rings. Without slip rings, these machines would face challenges in terms of power supply interruptions, unreliable data transmission, and potential damage to cables.The anonymous company is committed to continuous innovation and improvement of their slip ring offerings. They invest heavily in research and development to stay ahead of the technology curve, ensuring their customers have access to the latest advancements in slip ring design and performance. With a dedicated team of engineers and technicians, the company designs and manufactures custom solutions to meet specific customer requirements.In conclusion, signal and power slip rings have become indispensable components in various industries, enabling seamless transmission of power and signals between stationary and rotating parts. With a commitment to innovation and technology, the anonymous slip ring manufacturer (need removing brand name) continues to play a vital role in revolutionizing the efficiency and reliability of machinery across industries.

High-quality Slip Ring Assembly for Seamless Power and Data Transmission

Slip Ring Complete Assembly is an essential component in many industries and applications, including robotics, military, aerospace, and medical equipment. It allows for the transmission of power and electrical signals from a stationary to a rotating structure, making it an integral part of various machinery and devices. One of the leading manufacturers of Slip Ring Complete Assembly is {}, a company that has been at the forefront of technological innovation and engineering excellence for over 30 years. With a strong focus on research and development, the company has continually pushed the boundaries of slip ring technology, delivering high-quality products that meet the evolving needs of its customers.{} has recently introduced a new line of Slip Ring Complete Assembly that promises to set new standards in terms of performance and reliability. This latest offering is the result of years of dedicated research and development, as well as valuable feedback from customers and industry experts. The company's commitment to excellence is evident in every aspect of the product, from its advanced design to its superior quality materials and manufacturing processes.The new Slip Ring Complete Assembly from {} boasts several key features that set it apart from the competition. Firstly, it is designed to deliver exceptional electrical performance, with low electrical noise and minimal signal interference. This is crucial for applications where precision and accuracy are paramount, such as in medical imaging equipment and laboratory instruments. Additionally, the assembly is built to withstand harsh operating environments, with high levels of shock and vibration resistance, as well as protection against dust, moisture, and extreme temperatures.In terms of mechanical performance, {}'s Slip Ring Complete Assembly offers high rotational speed capabilities and smooth, maintenance-free operation. This is essential for applications that require continuous and uninterrupted rotation, such as robotics, radar systems, and surveillance cameras. The assembly is also modular and customizable, allowing for easy integration into a wide range of machinery and devices while accommodating specific design requirements.With a strong commitment to quality and customer satisfaction, {} ensures that its products undergo rigorous testing and certification processes to meet the highest industry standards. This includes extensive performance testing, durability assessments, and compliance with international regulations and safety standards. As a result, customers can have full confidence in the reliability and longevity of the Slip Ring Complete Assembly from {}.In addition to its technical capabilities, {} is also known for its exceptional customer service and support. The company's team of engineers and technical experts are available to provide guidance and assistance to customers, from product selection to installation and ongoing maintenance. This level of personalized support ensures that customers can fully leverage the potential of {}'s Slip Ring Complete Assembly, optimizing its performance and longevity in their specific applications.As the demand for advanced slip ring technology continues to grow across various industries, {} remains dedicated to staying at the forefront of innovation, delivering cutting-edge solutions that address the evolving needs of its customers. With its latest line of Slip Ring Complete Assembly, the company once again demonstrates its commitment to excellence, setting new benchmarks for performance, reliability, and customer satisfaction.Overall, {}'s Slip Ring Complete Assembly is the perfect combination of advanced technology, superior quality, and unmatched customer service, making it the top choice for customers in need of reliable and high-performance slip ring solutions.

Choosing Between Standard and Custom Slip Rings and Inductive, Capacitive, and Wetted Mercury Variations: Exploring Options for Advanced Components

As technological advancements continue to grow, machines become more complex, requiring advanced components to keep them functioning smoothly. Among the crucial parts in these machines are slip rings. They play a critical role in transmitting power and electrical signals from the stationary to the rotating components of a machine.Slip-rings come in different varieties, including inductive, capacitive, and wetted mercury variations. The advanced components range in bore sizes from half an inch to many feet in diameter, designed for medical imaging machines, livestock service systems, and other applications. However, the variations go beyond mere scale, and this poses a challenge for OEMs and design engineers, who must choose between standard and custom options and other critical factors to ensure the optimal slip-ring performance.Custom Slip Ring DesignOne of the factors that OEMs and design engineers consider when choosing between standard and custom slip rings is design flexibility. Custom slip ring design opens up limitless possibilities for machine designers, enabling them to tailor the slip rings to their specific requirements. Such flexibility allows for greater precision and control while saving on space, leading to a properly functioning system. It also eliminates the need for modifications after installation, making the final product more efficient.The design flexibility offered by custom slip rings provides OEMs and design engineers with a competitive advantage. With the ability to create customized slip rings built to precise specifications, they can offer their customers a unique solution, satisfying their specific needs and preferences.Reliability and PerformanceAnother critical factor when choosing between standard and custom slip rings is reliability and performance. The standard slip-ring options often lack the specialized features that different industries may require, leading to suboptimal performance. Custom slip rings ensure that all the elements required for optimal performance are included in the design, leading to a reliable, long-lasting, and efficient machine. This includes features such as high-temperature capabilities, corrosion resistance, and vibration absorption.The ability to customize slip rings also creates the opportunity for customized testing and validation processes. This ensures that the slip ring meets the specific application requirements and performs flawlessly without breakdowns and component failure.Cost ConsiderationsWhen choosing between standard and custom slip rings, cost considerations play a significant role. While customization offers the advantage of precision and optimal performance, it may be more expensive than off-the-shelf designs. Factors that affect custom slip ring cost include the design complexity, the materials used, production process, testing procedures, and validation.However, the cost of custom slip rings should not be a significant concern when considering the advantages that it can offer. Customization often results in increased production efficiency and decreased downtime, which ultimately lowers the operational costs of the machine in the long run.In conclusion, while choosing between standard and custom slip rings, OEMs and design engineers should consider several factors, including design flexibility, reliability, performance, and cost. Custom slip rings offer the advantage of precision and control, leading to greater efficiency, fewer modifications, and lower operation costs. Custom slip rings design is the perfect solution for those looking to create machines with specialized features that deliver optimal performance.

Discover the Revolutionary Advancements of Embedded High Speed Slip Rings

Title: Revolutionary Embedded High-Speed Slip Rings: Pioneering Breakthroughs in Power and Data TransmissionIntroduction and Company Overview:Innovation and technological advancements continue to redefine the way machines and systems function across various industries. Among these advancements, the development of Embedded High-Speed Slip Rings has emerged as a promising breakthrough in power and data transmission. This article will delve into the incredible potential of these slip rings while keeping the company's identity anonymous.With extensive experience in the field, our featured company has garnered a reputation for its cutting-edge engineering solutions. As leaders in slip ring technology, they have recently introduced their groundbreaking Embedded High-Speed Slip Rings, marking a significant step forward in the field.1. The Emergence of Embedded High-Speed Slip Rings:Embedded High-Speed Slip Rings have emerged as indispensable components for machines and systems requiring continuous rotation while transmitting power and data signals. These slip rings facilitate seamless transmission, ensuring optimum performance and efficiency across a spectrum of industries.2. Advantages and Features:Embedded High-Speed Slip Rings offer a multitude of advantages that set them apart from traditional slip rings. Here are some notable features:a) Compact Design: The embedded design ensures a compact form factor, making them highly suitable for applications with limited space.b) Enhanced Signal Integrity: These slip rings excel at maintaining signal integrity, enabling high-quality data transmission without loss or interference.c) High Rotational Speed: Designed to accommodate high rotational speeds, these slip rings maintain exceptional performance, even under demanding conditions.d) Low Electrical Noise: Advanced insulation and grounding techniques significantly reduce electrical noise, ensuring clean and reliable data and power transmission.e) Longevity and Durability: Employing high-quality materials combined with excellent engineering, these slip rings are designed to withstand rigorous working environments, providing long-lasting and reliable operation.3. Industrial Applications:Embedded High-Speed Slip Rings find applications in various industries, revolutionizing power and data transmission across critical applications. The following sectors substantially benefit from their advanced capabilities:a) Robotics and Automation: In fields like industrial automation and robotics, high-speed rotational movement combined with reliable and uninterrupted power and data transmission is crucial. Embedded High-Speed Slip Rings help maintain the performance and integrity of these systems.b) Medical Equipment: Medical devices require precision, reliability, and seamless communication between various components. Embedded High-Speed Slip Rings ensure uninterrupted power supply and continuous data transmission for diagnostic imaging equipment, robotic surgical systems, and more.c) Defense and Aerospace: The defense and aerospace sectors often rely on slip rings in systems such as communication antennas, radar systems, and missile launchers. Embedded High-Speed Slip Rings enhance communication accuracy and efficiency, playing a vital role in these critical applications.d) Wind Turbines: In the renewable energy sector, slip rings are used in wind turbines to transfer electrical power from the rotating blades to the stationary circuitry. Embedded High-Speed Slip Rings guarantee efficient power transmission, contributing to optimal energy generation.e) Broadcasting and Communication: Media equipment, such as rotating cameras and specialized broadcasting equipment, necessitate reliable transmission of power and uninterrupted data connectivity. Embedded High-Speed Slip Rings ensure continuous and high-speed signal transmission, facilitating smooth broadcasting operations.4. Conclusion:Embedded High-Speed Slip Rings have revolutionized the mechanism by which power and data are transferred in various industries. With advancements in technology and continual innovation, these slip rings contribute immensely to increased efficiency, improved performance, and seamless connectivity.As the demand for high-speed, reliable, and durable slip rings grows, companies like our featured partner remain at the forefront of engineering extraordinary solutions. Their Embedded High-Speed Slip Rings exemplify the industry's commitment to pushing boundaries and creating the foundations for a technologically advanced future.