High-Quality Slip Ring Technology: The Latest Innovations in Rotary Electrical Connectors

By:Admin

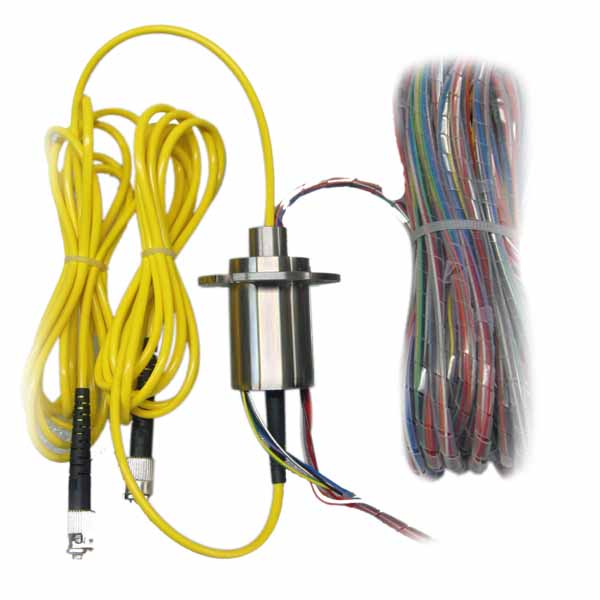

Taidacent Slip Ring, a leading manufacturer of rotary electrical connectors, has recently introduced an innovative solution that promises to revolutionize the way electrical connections are made in rotary applications. This new product has been designed to address the growing demand for reliable and efficient electrical transmission in a wide range of industries, including robotics, medical devices, wind turbines, and industrial machinery.

The slip ring is a critical component in many rotating electrical systems, allowing for the transmission of power, data, and signals between stationary and rotating parts. However, traditional slip rings often suffer from limitations such as wear and tear, limited lifespan, and a lack of adaptability to various environmental conditions. In response to these challenges, Taidacent Slip Ring has developed a cutting-edge solution that promises to deliver higher performance and longer service life.

One of the key features of the new slip ring is its advanced design, which incorporates the latest technology in electrical connectivity. Through the use of high-quality materials and precision engineering, Taidacent Slip Ring has been able to create a product that offers superior electrical transmission with minimal maintenance requirements. This means that customers can expect increased reliability and efficiency in their rotary applications, leading to a reduction in downtime and operating costs.

In addition to its enhanced performance, the new slip ring also boasts a high degree of flexibility and adaptability. It can be customized to meet the specific needs of different applications, allowing for seamless integration into a wide range of rotating systems. This versatility makes it an ideal choice for manufacturers looking to streamline their production processes and improve the overall performance of their equipment.

Furthermore, Taidacent Slip Ring has gone to great lengths to ensure that its product meets the highest standards of quality and safety. The new slip ring has been subjected to rigorous testing and certification procedures, demonstrating its compliance with industry regulations and requirements. As a result, customers can have full confidence in the reliability and safety of this innovative solution.

The introduction of this new slip ring marks a significant milestone for Taidacent Slip Ring, further solidifying its position as a leading provider of rotary electrical connectors. With a strong commitment to innovation and continuous improvement, the company has demonstrated its ability to develop cutting-edge solutions that address the evolving needs of the market.

In line with its dedication to customer satisfaction, Taidacent Slip Ring also offers comprehensive technical support and customer service to ensure that customers can fully leverage the benefits of its products. This includes assistance with product selection, installation guidance, and ongoing maintenance and troubleshooting.

The company's commitment to excellence extends beyond its products and services, as it also places a strong emphasis on environmental responsibility and sustainability. Taidacent Slip Ring is committed to minimizing its impact on the environment through the adoption of eco-friendly manufacturing practices and the use of recyclable materials.

Looking ahead, Taidacent Slip Ring remains focused on driving innovation and delivering value to its customers. With a strong track record of success and a clear vision for the future, the company is well-positioned to continue shaping the future of rotary electrical connections.

In conclusion, the introduction of the new slip ring from Taidacent Slip Ring represents a significant advancement in the field of rotary electrical connectors. With its superior performance, flexibility, and safety features, this innovative solution promises to set a new standard for electrical transmission in rotating systems. As industries continue to evolve and demand higher levels of efficiency and reliability, Taidacent Slip Ring is well-prepared to meet these needs with its cutting-edge technology and commitment to customer satisfaction.

Company News & Blog

High-quality Slip Ring Assembly for Seamless Power and Data Transmission

Slip Ring Complete Assembly is an essential component in many industries and applications, including robotics, military, aerospace, and medical equipment. It allows for the transmission of power and electrical signals from a stationary to a rotating structure, making it an integral part of various machinery and devices. One of the leading manufacturers of Slip Ring Complete Assembly is {}, a company that has been at the forefront of technological innovation and engineering excellence for over 30 years. With a strong focus on research and development, the company has continually pushed the boundaries of slip ring technology, delivering high-quality products that meet the evolving needs of its customers.{} has recently introduced a new line of Slip Ring Complete Assembly that promises to set new standards in terms of performance and reliability. This latest offering is the result of years of dedicated research and development, as well as valuable feedback from customers and industry experts. The company's commitment to excellence is evident in every aspect of the product, from its advanced design to its superior quality materials and manufacturing processes.The new Slip Ring Complete Assembly from {} boasts several key features that set it apart from the competition. Firstly, it is designed to deliver exceptional electrical performance, with low electrical noise and minimal signal interference. This is crucial for applications where precision and accuracy are paramount, such as in medical imaging equipment and laboratory instruments. Additionally, the assembly is built to withstand harsh operating environments, with high levels of shock and vibration resistance, as well as protection against dust, moisture, and extreme temperatures.In terms of mechanical performance, {}'s Slip Ring Complete Assembly offers high rotational speed capabilities and smooth, maintenance-free operation. This is essential for applications that require continuous and uninterrupted rotation, such as robotics, radar systems, and surveillance cameras. The assembly is also modular and customizable, allowing for easy integration into a wide range of machinery and devices while accommodating specific design requirements.With a strong commitment to quality and customer satisfaction, {} ensures that its products undergo rigorous testing and certification processes to meet the highest industry standards. This includes extensive performance testing, durability assessments, and compliance with international regulations and safety standards. As a result, customers can have full confidence in the reliability and longevity of the Slip Ring Complete Assembly from {}.In addition to its technical capabilities, {} is also known for its exceptional customer service and support. The company's team of engineers and technical experts are available to provide guidance and assistance to customers, from product selection to installation and ongoing maintenance. This level of personalized support ensures that customers can fully leverage the potential of {}'s Slip Ring Complete Assembly, optimizing its performance and longevity in their specific applications.As the demand for advanced slip ring technology continues to grow across various industries, {} remains dedicated to staying at the forefront of innovation, delivering cutting-edge solutions that address the evolving needs of its customers. With its latest line of Slip Ring Complete Assembly, the company once again demonstrates its commitment to excellence, setting new benchmarks for performance, reliability, and customer satisfaction.Overall, {}'s Slip Ring Complete Assembly is the perfect combination of advanced technology, superior quality, and unmatched customer service, making it the top choice for customers in need of reliable and high-performance slip ring solutions.

Exploring the Realm of Super Miniature 6mm Capsule Slip Rings: A Comprehensive Guide on Slip Ring Products and Production

Title: Enhancing Connectivity with Twist Capsule Slip Rings: A Comprehensive GuideIntroduction:In an ever-evolving technological landscape, seamless connectivity plays a crucial role in various industries. To ensure uninterrupted data transmission, slip rings have emerged as a vital component. Among them, Twist Capsule Slip Rings have garnered attention due to their super miniature size and exceptional performance. In this blog, we will explore the features, applications, and production process of these revolutionary slip rings.Understanding Twist Capsule Slip Rings:Twist Capsule Slip Rings, also known as super miniature slip rings, are compact devices designed to transfer electrical signals and power across rotating interfaces. With an outer diameter as small as 6mm, these slip rings offer remarkable versatility and can operate in confined spaces with limited clearance. Their unique design allows for unrestricted 360-degree rotation, making them ideal for applications that involve continuous rotation.Key Features:1. Miniature Design: The compact size of Twist Capsule Slip Rings enables their integration into space-restricted applications, without compromising on performance or reliability.2. Multi-channel Signal Transmission: These slip rings can transmit a wide range of signals, including data, audio, video, and power, simultaneously. This versatility makes them suitable for diverse industries such as robotics, medical equipment, surveillance systems, and drones.3. Low Electrical Noise: With advanced design and superior engineering, Twist Capsule Slip Rings exhibit low electrical noise, ensuring high-quality signal transmission.4. High Rotational Speed: These slip rings are built to withstand high-speed rotations, making them ideal for demanding applications that require continuous and precise transmission of signals, such as automation machinery and precision instruments.5. Long Service Life: Manufactured with high-quality materials, Twist Capsule Slip Rings offer exceptional durability, ensuring a prolonged service life even under harsh conditions.Applications:The compact size and versatile nature of Twist Capsule Slip Rings have revolutionized multiple industries and applications. Some notable areas where these slip rings find extensive usage include:1. Robotics and Automation: Twist Capsule Slip Rings enable seamless communication between rotating components of robotic arms, allowing for uninterrupted control signals and power transmission.2. Medical Equipment: In medical devices such as endoscopes and surgical robots, Twist Capsule Slip Rings play a vital role in the transmission of video signals, power, and data between the stationary and rotating parts.3. Surveillance Systems: Compact slip rings facilitate smooth rotation of PTZ (pan-tilt-zoom) cameras in surveillance systems, ensuring uninterrupted transmission of video signals.4. Drones and UAVs: Twist Capsule Slip Rings enable continuous transmission of power and control signals between the stationary body and rotating parts of drones, enabling smooth operation and precise control.Production Process:To ensure the highest quality and reliability, the production process of Twist Capsule Slip Rings entails several critical steps:1. Design and Engineering: The slip ring's design is meticulously engineered using advanced CAD software, taking into consideration factors such as size, materials, number of circuits, and rotational speed requirements.2. Component Selection: High-quality materials, such as gold alloy, stainless steel, and specialized plastics, are carefully chosen to ensure optimum electrical conductivity, durability, and resistance to wear and tear.3. Precision Manufacturing: Utilizing cutting-edge technologies like CNC machining and automated assembly, the slip rings are manufactured with utmost precision, maintaining tight tolerances for seamless operation.4. Quality Testing: Rigorous quality control tests are conducted throughout the manufacturing process to guarantee the slip rings' performance and durability. These assessments include electrical testing, rotational speed testing, and vibration testing.5. Final Inspection and Packaging: After passing all quality tests, the Twist Capsule Slip Rings undergo a final inspection, where each unit is examined for defects. They are then carefully packaged to ensure damage-free delivery.Conclusion: Twist Capsule Slip Rings have revolutionized connectivity in numerous industries by offering a compact yet powerful solution for seamless data and power transmission. With their exceptional features, like miniature design, multi-channel signal transmission, and high rotational speed capabilities, these slip rings are redefining the concept of connectivity. So, whether it's robotics, medical equipment, surveillance systems, or drones, Twist Capsule Slip Rings are paving the way towards a more connected and efficient future.

Revolutionizing Connectivity: Discover the Power of Digital Slip Rings

Title: Innovative Digital Slip Ring Revolutionizes Modern Industrial OperationsIntroduction:In the fast-paced world of industrial automation, the relentless pursuit of innovation has reshaped traditional manufacturing processes. With the advent of advanced technologies, businesses seek to increase efficiency, improve reliability, and minimize downtime. In line with this spirit of innovation, a renowned company has developed a cutting-edge Digital Slip Ring (brand name omitted), poised to redefine the landscape of industrial operations.[Company Name] - Pioneers in Industrial Automation:As a leading player in the industrial automation market, [Company Name] has a long-standing reputation for providing state-of-the-art solutions to a diverse range of industries. With a dedicated team of engineers and researchers, the company has consistently harnessed technology to develop groundbreaking products. Specializing in slip ring technology, [Company Name] has now introduced a revolutionary Digital Slip Ring, promising to enhance performance while meeting the specific demands of modern industrial operations.The Era of Digital Slip Rings:Traditional slip rings played a vital role in transmitting power, electrical signals, and data across rotating interfaces. However, as industries evolved and embraced the digital era, the limitations of traditional slip rings began to surface. Recognizing this need for enhanced communication capabilities, [Company Name] invested extensive resources and expertise to develop an industry-leading Digital Slip Ring.Pioneering Technology and Features:The Digital Slip Ring developed by [Company Name] boasts several cutting-edge features that address the limitations of its predecessors. Marking a significant leap forward in slip ring technology, this innovative product offers the following advantages:1. High-Speed Data Transmission: With its advanced signal processing capabilities, the Digital Slip Ring allows for smooth and uninterrupted data transmission across rotational interfaces. This ensures real-time communication between rotating and stationary parts, facilitating critical industrial operations reliant on accurate data exchange.2. Improved Signal Quality: Signal integrity is a critical concern in industrial automation applications. The Digital Slip Ring ensures minimal signal loss, resulting in improved performance, reduced downtime, and increased operational efficiency.3. Enhanced Connectivity: Offering a wide array of channels, the Digital Slip Ring supports the seamless transmission of power, electrical signals, and data. This versatility allows businesses in industries such as robotics, aerospace, and manufacturing to streamline their operations effectively.4. Compact Design: Recognizing the importance of space optimization, [Company Name] has incorporated a compact design into their Digital Slip Ring. This facilitates easy integration into existing systems, reducing the need for complex and time-consuming modifications.5. Durability and Reliability: The Digital Slip Ring is engineered to withstand harsh operating conditions, such as high temperatures, extreme pressures, and mechanical vibrations. This robust solution significantly improves the longevity and reliability of industrial automation systems.6. Compatibility and Integration: [Company Name]'s Digital Slip Ring can seamlessly integrate with a variety of industrial protocols, ensuring compatibility with diverse automation systems. Furthermore, its easy integration allows for hassle-free upgrades and replacements, saving both time and resources.The Future of Industrial Automation:The introduction of [Company Name]'s Digital Slip Ring heralds a new era for industrial automation. With its ability to facilitate high-speed data transmission, improve signal quality, and offer unparalleled connectivity, this innovative product has the potential to transform various industries.By incorporating the Digital Slip Ring into their operations, companies can expect enhanced efficiency, reduced downtime, and increased productivity. This, in turn, will allow them to remain competitive in the dynamic and rapidly evolving industrial landscape.Conclusion:[Company Name]'s Digital Slip Ring has set a new standard in the field of slip ring technology. Through its cutting-edge features, it surpasses the limitations of traditional slip rings, addressing the demands of modern industrial operations. As businesses increasingly embrace automation and digitization, this innovative product ensures seamless communication, increased efficiency, and improved reliability, thus driving industrial operations into the future.

Top Slip Ring Technologies in Modern Wind Turbines

Title: New Slip Ring Technology Revolutionizes Wind Turbine EfficiencyIntroduction:In recent years, renewable energy has emerged as a crucial solution to combat climate change. Wind power, in particular, has gained significant traction due to its immense potential to generate clean and sustainable electricity. One vital component that plays a crucial role in the functioning of wind turbines is the slip ring. Today, we will explore a groundbreaking slip ring technology developed by a renowned industry leader, aimed at revolutionizing wind turbine efficiency.[Company Introduction]:Founded with a mission to drive innovation in renewable energy, this cutting-edge company is a recognized global leader in slip ring technology. With a rich history spanning over several decades, they have continually pushed boundaries to develop efficient, reliable, and sustainable solutions for wind turbines. Operating under a strong commitment to sustainability, the company strives to provide the industry with advanced products that contribute to a greener future.[News Content]: 1. The Need for Advanced Slip Ring Technology:Wind turbines are an essential source of clean energy, but their efficiency can be hindered by various factors, including mechanical wear, electrical noise, and power loss. These issues are particularly problematic in traditional slip ring systems. Recognizing this, the company has developed an innovative slip ring technology that addresses these concerns, significantly improving wind turbine performance.2. Enhanced Efficiency and Reliability:The new slip ring technology boasts a range of features that greatly enhance both the efficiency and reliability of wind turbines. By employing advanced materials and manufacturing techniques, the company has achieved a significant reduction in power loss, enabling turbines to generate more electricity. Additionally, the slip ring design ensures a smoother rotation, minimizing mechanical wear and maximizing the turbine's lifespan.3. Cutting-Edge Electrical Noise Mitigation:Electrical noise is a common occurrence in wind turbines, resulting from various factors such as electromagnetic interference and contact resistance. This disruptive interference affects the turbine's electronics and can lead to malfunctions or inefficiencies. The company's slip ring technology incorporates state-of-the-art noise reduction mechanisms, significantly reducing both the generation and transmission of electrical noise within the turbine.4. Minimal Maintenance and Downtime:Another key advantage of this advanced slip ring technology is its ability to drastically reduce maintenance requirements and associated downtime. Traditional slip rings often necessitate frequent checks and replacements, resulting in substantial operational disruptions. However, with the implementation of this new technology, wind turbine operators can enjoy extended periods of uninterrupted energy generation, resulting in higher overall productivity.5. A Sustainable Solution:In line with the company's commitment to sustainability, this new slip ring technology is designed to minimize the environmental impact of wind turbines. By reducing power loss and increasing efficiency, turbine operations become more eco-friendly, optimizing energy output and reducing the need for additional resources. This cutting-edge technology provides a significant opportunity to accelerate the transition to a more sustainable energy sector.6. Industry Impact and Future Prospects:The introduction of this revolutionary slip ring technology not only benefits wind turbine operators but also has far-reaching implications for the renewable energy industry as a whole. By maximizing turbine performance and reliability, this technology enables the widespread adoption of wind energy as a vital component of global electricity generation. As renewable energy demands continue to rise, it is anticipated that the company's innovation will contribute significantly to the growth and success of the sector.Conclusion:With their groundbreaking slip ring technology, this industry-leading company has revolutionized wind turbine efficiency. Through improved power transmission, reduced electrical noise, and enhanced reliability, this innovative solution drives the wind energy sector closer to a greener and more sustainable future. As the world continues its transition towards renewable energy, advancements like these are crucial in shaping a cleaner and more prosperous tomorrow.

Small Capsule Slip Ring - A Compact Solution for Efficient Electrical Transmission

Title: Miniature Slip Ring Capsule: Revolutionizing Rotary Transmission TechnologyIntroduction:In today's rapidly advancing technological landscape, the demand for miniaturized yet efficient rotary transmission systems has been steadily growing. Enter the Miniature Slip Ring Capsule (name removed), an innovative and game-changing solution developed by an industry-leading company (name removed). This groundbreaking device represents a paradigm shift in rotary transmission technology, offering unparalleled capabilities in a compact and versatile design.I. A New Era of Rotary Transmission:The Miniature Slip Ring Capsule heralds a new era of rotary transmission technology, enabling the seamless transfer of electrical signals and power between rotating and stationary structures. Its compact size, weighing only a few grams and measuring a few centimeters, is a remarkable achievement that sets it apart from conventional slip ring solutions.II. Key Features and Design:The Miniature Slip Ring Capsule is built on cutting-edge engineering principles, incorporating key features that make it a highly sought-after solution in various industries. With a low electrical noise and minimal friction, the slip rings ensure smooth signal transfer and are compatible with a wide range of applications. The maintenance-free design eliminates the need for regular check-ups and ensures its longevity in demanding environments.III. Versatility and Applications:The versatility of the Miniature Slip Ring Capsule makes it suitable for integration into an array of industries and applications. From medical devices to aerospace systems, from robotics to wind turbines, this solution offers a reliable and efficient method for transferring power and data signals despite rotational movements. Its compatibility with high-speed data transmission ensures exceptional performance, making it an ideal choice for data-driven processes.IV. Advantages and Benefits:The Miniature Slip Ring Capsule brings forth several advantages that set it apart from traditional rotary transmission methods. Its compact size allows for seamless integration into existing equipment without significant modifications. The slip ring's high precision and low friction translate into a reduction in signal loss, providing accurate and reliable data transfer. Furthermore, its robust construction ensures operation in extreme temperatures and adverse environmental conditions.V. Industry-leading Technology:The Miniature Slip Ring Capsule owes its exceptional performance to the forward-thinking approach and extensive research and development carried out by (company name removed). The company, renowned for its expertise in rotary transmission systems, has a proven track record of delivering cutting-edge solutions to meet the evolving needs of various industries. Their commitment to continuous innovation and emphasis on quality make them a trusted partner for customers worldwide.VI. Market Impact and Future Prospects:The introduction of the Miniature Slip Ring Capsule has made a significant impact on the rotary transmission market, prompting industries to reimagine their equipment design and functionality. The compact size and unrivaled performance of this technology have opened doors to new possibilities in sectors such as robotics, automation, and renewable energy. With ongoing advancements and the increasing demand for efficient rotary transmission systems, the outlook for the Miniature Slip Ring Capsule remains highly promising.Conclusion:The Miniature Slip Ring Capsule represents a milestone achievement in rotary transmission technology, revolutionizing the industry with its compact size, remarkable performance, and versatile applications. Developed by the pioneering efforts of (company name removed), this breakthrough device is set to shape the future of rotary transmission, enabling seamless power and data transfer in various industries. As technology continues to advance, the Miniature Slip Ring Capsule paves the way for new possibilities and sets the bar for miniaturized yet efficient rotary transmission systems.

High-Quality Slip Ring of Single-Channel High Frequency Rotary Joint with Small Size for Precise Instrument: A Chinese Product

Gimbal Small Size Slip Rings: Offering High-Quality Slip Ring of Single-Channel High-Frequency Rotary Joint with Small Size for Precise InstrumentsIn the world of precision instruments, having reliable and efficient rotary joints is of utmost importance. These rotary joints play a crucial role in transmitting signals and power between the stationary and rotating parts of various devices such as gimbals, drones, cameras, and robotic arms. A slip ring is one such rotary joint that has gained significant attention due to its ability to transmit signals and power continuously while rotating.China, being a global manufacturing hub, has emerged as a leading player in slip ring production. Among the many manufacturers, there is one company that stands out for its commitment to producing high-quality slip rings – Gimbal Small Size Slip Rings.Gimbal Small Size Slip Rings is a renowned name in the slip ring industry, known for its focus on precision and reliability. Their latest offering, the Slip Ring of Single-Channel High-Frequency Rotary Joint with Small Size for Precise Instruments, has garnered attention for its superior performance and compact design.The slip ring is designed keeping in mind the requirements of precise instruments. With a single-channel high-frequency rotary joint, it enables the transmission of signals at high frequencies without compromising on quality. This makes it ideal for devices that demand quick and accurate data transmission, such as robotic control systems and high-speed cameras.One of the standout features of the slip ring is its small size. Gimbal Small Size Slip Rings understands the importance of space-saving designs, especially in compact instruments and gadgets. The compact size of this slip ring allows for easy integration into devices without adding unnecessary bulk or hindering their functionality. This opens up new possibilities for miniaturization in various industries, where space optimization is crucial.Strict quality control is an integral part of Gimbal Small Size Slip Rings' manufacturing process. They are committed to delivering slip rings that meet the highest industry standards. Their slip rings undergo rigorous testing and quality checks, ensuring consistent and reliable performance. With years of experience and advanced manufacturing techniques, Gimbal Small Size Slip Rings has earned a reputation for producing slip rings that are robust, durable, and long-lasting.The slip rings offered by Gimbal Small Size Slip Rings also boast efficient power transmission capabilities. With low electrical noise and minimal voltage drop, these slip rings ensure smooth and uninterrupted power supply to connected devices. This is particularly important in instruments that rely on precise power delivery, as any fluctuations or interruptions in power can result in inaccurate readings or system failures.Gimbal Small Size Slip Rings' slip rings are also highly versatile. They can be customized to meet specific requirements, including different signal channels, frequency ranges, and power ratings. This flexibility allows for seamless integration into a wide range of instruments, making them suitable for various applications in industries such as aerospace, defense, automation, and medical.In conclusion, Gimbal Small Size Slip Rings has proven itself as a leading manufacturer of high-quality slip rings. Their Slip Ring of Single-Channel High-Frequency Rotary Joint with Small Size for Precise Instruments stands out for its compact design, excellent signal transmission capabilities, and strict adherence to quality standards. As the demand for precise instruments continues to grow, having reliable slip rings like those offered by Gimbal Small Size Slip Rings will be crucial for ensuring accurate and efficient performance.

Top Slip Ring Assemblies for Efficient Signal Transmission Explained

Title: Revolutionary Slip Ring Assemblies: Breaking Boundaries in Advanced ManufacturingIntroductionIn a groundbreaking move, a cutting-edge technological company is set to redefine the landscape of advanced manufacturing with its revolutionary slip ring assemblies. Utilizing innovative engineering practices and state-of-the-art materials, this company aims to propel industries forward by offering seamless electrical connections in rotating machinery. With an unwavering commitment to pushing the boundaries of what is possible, their slip ring assemblies are paving the way for more efficient, reliable, and precision-controlled operations across various sectors.Revolutionizing Rotating MachineryFrom robotic arms and wind turbines to medical equipment and radars, rotating machinery has become an integral part of several industries. However, one of the fundamental challenges faced by these industries is the transmission of power and signals across the rotating interface between the stationary and rotating parts of the machinery. This is precisely where the slip ring assemblies provided by this pioneering company step in to revolutionize operations.Uninterrupted Power and Data TransmissionThe slip ring assemblies designed by this company ensure uninterrupted transmission of power and data signals, enabling unrestricted rotation and maximum efficiency. By utilizing advanced conductive materials and precision engineering, they have successfully eliminated the limitations traditionally associated with mechanical connections. These slip rings facilitate the seamless transfer of electricity, data, and signals, resulting in enhanced productivity, reduced maintenance, and improved overall system performance.Cutting-Edge TechnologyThe slip ring assemblies provided by this company are built to withstand demanding environments while maintaining optimal performance. Their engineers leverage the latest technologies to develop products that excel in extreme temperatures, harsh weather conditions, and high-speed applications. Through meticulous research and rigorous testing, this company ensures that its slip ring assemblies meet and exceed industry standards, guaranteeing longevity and reliability in challenging operational environments.Customized Solutions for Diverse IndustriesRecognizing the diverse needs of various industries, this company offers highly customizable slip ring assemblies to cater to specific requirements. They work closely with clients to understand their unique challenges and provide tailored solutions that seamlessly integrate with existing machinery. With an extensive range of slip ring designs, this company ensures compatibility with a wide array of applications, resulting in improved efficiency, reduced downtime, and increased operational flexibility.Expert Consultation and After-Sales SupportThis company's commitment to its clients does not end with the sale of its slip ring assemblies. Their team of highly experienced engineers provides expert consultation on slip ring selection, installation, and maintenance, ensuring optimal performance and longevity of their products. Additionally, their dedicated after-sales support team is readily available to address any concerns or issues, guaranteeing a seamless experience throughout the entire lifecycle of the slip ring assemblies.Driving Industrial AdvancementIn addition to their focus on creating advanced slip ring assemblies, this company actively contributes to driving industrial advancement. They collaborate with research institutions, universities, and industry leaders to stay at the forefront of emerging technologies and industry trends. By fostering innovation and knowledge sharing, they aim to continuously improve and develop cutting-edge solutions that address the evolving needs of modern manufacturing.ConclusionWith their revolutionary slip ring assemblies, this cutting-edge technological company is reshaping the landscape of advanced manufacturing. Bolstered by state-of-the-art engineering practices, these slip rings enable uninterrupted power and data transmission, ensuring seamless rotation and superior efficiency. By offering customized solutions and expert consultation, this company is empowering diverse industries to overcome long-standing challenges and achieve unprecedented levels of productivity. With their unwavering commitment to excellence and continuous innovation, they are poised to drive industrial advancement into the future.

Innovative Slip Ring System for Smooth Power and Data Transmission

The Slip Ring System market is anticipated to grow significantly in the coming years, as per a new research report by [Company Name]. Slip ring systems are electromechanical devices used to transfer electrical power, signal, and data from a stationary to a rotating structure. The global slip ring system market is projected to witness substantial growth during the forecast period, driven by the increasing demand for slip ring systems in various industries such as aerospace, defense, manufacturing, and robotics.[Company Name] is a leading manufacturer of slip ring systems, with a strong focus on delivering high-quality products that meet the specific requirements of their diverse customer base. The company's extensive experience in slip ring technology, combined with their commitment to innovation, has positioned them as a key player in the global slip ring system market.The demand for slip ring systems in the aerospace and defense sector is expected to drive the growth of the market. Slip rings are widely used in military aircraft, radar systems, and communication equipment, among others, due to their ability to transfer power and data between a stationary and rotating structure. With the increasing defense budgets in several countries and the growing focus on modernizing defense equipment, the demand for slip ring systems is expected to surge in the coming years.In addition to the aerospace and defense sector, the manufacturing industry is also a significant contributor to the growth of the slip ring system market. The use of slip rings in manufacturing machinery and equipment for automation and robotics applications is driving the demand for these systems. As industries continue to adopt advanced manufacturing technologies and robotics, the need for reliable slip ring systems becomes increasingly critical.Furthermore, the rise in demand for slip ring systems in offshore wind turbines and other renewable energy applications is expected to create new opportunities for market growth. As the world shifts towards renewable energy sources, the need for reliable and efficient slip ring systems in wind turbines and other renewable energy equipment will drive the market forward.[Company Name] has been at the forefront of providing innovative slip ring solutions to meet the evolving needs of various industries. The company's extensive portfolio of slip ring systems includes standard and custom-designed solutions to cater to a wide range of applications. Their commitment to quality and reliability has earned them a strong reputation in the industry, making them a preferred choice for customers globally.The company's expertise in slip ring technology, coupled with their dedication to customer satisfaction, has allowed them to establish strong business partnerships with leading companies in the aerospace, defense, manufacturing, and renewable energy sectors. Their ability to deliver tailored solutions that meet the specific requirements of their customers has set them apart in the market.As the global demand for slip ring systems continues to grow, [Company Name] remains committed to driving innovation and delivering cutting-edge solutions to their customers. With a focus on quality, reliability, and customer satisfaction, the company is well-positioned to capitalize on the opportunities presented by the expanding slip ring system market.In conclusion, the global slip ring system market is set for significant growth in the coming years, driven by the increasing demand from various industries including aerospace, defense, manufacturing, and renewable energy. [Company Name] is poised to play a key role in this growth trajectory, with their advanced slip ring solutions and unwavering commitment to customer excellence. As the market evolves, [Company Name] remains dedicated to providing leading-edge slip ring systems that meet the ever-changing needs of their customers, ensuring a prosperous future in the global slip ring system market.

Quality Slip Ring Manufacturer for Electrical Transmission Applications

[Company Name], a leading slip ring manufacturer, has recently announced the launch of a new series of high-performance slip rings that are designed to meet the increasing demands of various industries.With a history of innovation and excellence, [Company Name] has been a pioneer in the development and production of slip rings and rotary joints. The company has continuously invested in research and development to create advanced solutions that cater to the needs of its customers.The new series of slip rings incorporates the latest technologies and materials to ensure reliable and efficient performance in demanding applications. These slip rings are designed to meet the requirements of industries such as aerospace, defense, medical, and robotics, where high reliability and precision are essential.One of the key features of the new series is the use of advanced materials that provide enhanced durability and electrical performance. The slip rings are also designed to operate in extreme environments, including high temperatures and corrosive conditions, making them suitable for a wide range of applications.In addition to their robust construction, the new slip rings are also engineered to deliver high electrical performance, with low electrical noise and signal loss. This ensures that they can be used in critical applications where signal integrity is paramount.The new series also includes customizable options to meet specific application requirements. Customers can choose from a range of sizes, configurations, and mounting options to ensure that the slip rings integrate seamlessly into their systems.Furthermore, [Company Name] has also introduced advanced sealing and protection features to ensure that the slip rings are well-suited for applications where environmental factors such as dust, moisture, and vibration are a concern. This makes them ideal for use in harsh operating conditions, such as heavy machinery and outdoor equipment.To support the launch of the new series, [Company Name] has also invested in expanding its manufacturing capabilities, ensuring that it can meet the increasing demand from its customers. The company has also strengthened its technical support and customer service to provide comprehensive assistance to its clients.In a statement, the spokesperson for [Company Name] emphasized the company's commitment to delivering top-quality products and exceptional service to its customers. "We are proud to introduce our new series of high-performance slip rings, which are a result of our dedication to innovation and continuous improvement. We are confident that these slip rings will exceed the expectations of our customers and provide them with reliable solutions for their critical applications."With its new series of high-performance slip rings, [Company Name] is set to further solidify its position as a leading provider of rotary transmission solutions. The company's dedication to technological advancement and customer satisfaction continues to drive its success in various industries.

High-Quality Customized Electrical Slip Ring for All Your Needs

Custom Electrical Slip Ring, a leading provider of high-quality slip rings, has recently expanded its product line to include innovative new designs that offer unprecedented performance and reliability for a wide range of applications. With over 20 years of experience in the industry, Custom Electrical Slip Ring has established itself as a trusted name in the field of slip ring technology, constantly striving to push the boundaries of what is possible and to meet the evolving needs of its customers.The latest additions to Custom Electrical Slip Ring's product line have been specifically engineered to address the growing demand for slip rings that can deliver exceptional levels of performance in even the most challenging environments. These new designs utilize cutting-edge materials and advanced engineering techniques to provide improved durability, efficiency, and versatility, making them ideal for use in a variety of industries, including aerospace, defense, robotics, and medical equipment.One of the most notable features of Custom Electrical Slip Ring's new products is their ability to handle higher levels of electrical power while minimizing signal interference, resulting in more reliable and consistent performance. This is particularly important for applications that require the transmission of large amounts of data or power over extended periods of time, as any interruption or degradation of the signal could have serious consequences. By incorporating the latest advancements in slip ring technology, Custom Electrical Slip Ring has succeeded in developing solutions that effectively address these challenges and deliver superior results.In addition to their outstanding technical capabilities, Custom Electrical Slip Ring's new products also stand out for their modular designs, which offer a high degree of flexibility and customization options. This allows customers to configure the slip rings to meet their specific requirements, ensuring a perfect fit for their individual needs. Moreover, the modular nature of these designs facilitates easier maintenance and repair, as components can be easily accessed and replaced as necessary, minimizing downtime and reducing overall cost of ownership.Furthermore, Custom Electrical Slip Ring takes great pride in its commitment to providing exceptional customer service and support. The company's team of experts works closely with clients to understand their unique challenges and objectives, offering personalized advice and guidance to help them select the most suitable slip ring solutions for their applications. This customer-centric approach has earned Custom Electrical Slip Ring a reputation for reliability and trustworthiness, as well as numerous satisfied customers who have benefited from the company's expertise and dedication.Looking ahead, Custom Electrical Slip Ring remains firmly focused on pushing the boundaries of slip ring technology and setting new standards for performance and reliability. With a strong emphasis on research and development, the company is continually exploring new materials, processes, and design concepts to further enhance its product offerings and stay ahead of the curve. By staying at the forefront of innovation, Custom Electrical Slip Ring is well-positioned to continue serving as a partner of choice for customers seeking advanced slip ring solutions.In conclusion, the latest additions to Custom Electrical Slip Ring's product line represent a significant milestone for the company, showcasing its dedication to delivering superior quality, performance, and reliability to its customers. With a strong focus on innovation and customer service, Custom Electrical Slip Ring is well-equipped to meet the evolving needs of a diverse range of industries and continue its legacy as a leading provider of high-quality slip ring solutions.