Enhance Excavator Performance with a Reliable Rotary Union

By:Admin

Innovation in the construction industry has always played a vital role in improving efficiency and productivity. As excavators continue to pave the way for groundbreaking developments in the sector, one component that has been constantly evolving is the excavator rotary union. By effectively joining hydraulic and electrical systems, this essential device has become instrumental in optimising the performance of excavators.

Rotary unions, known by various names including swivels or rotary joints, are dynamic components that allow for the transfer of fluid or gas from a stationary input to a rotating output in machinery. In the context of excavators, rotary unions play a pivotal role in connecting the hydraulic circuits responsible for operating the machinery, and ensure a seamless power supply during rotary motion. The ability to transmit hydraulic fluid and electrical signals under such conditions significantly enhances the performance, reliability, and versatility of excavators.

One prime example of an excavator rotary union that has revolutionised the industry is the product developed by {Company Name}. With their extensive experience and dedication to delivering high-quality components, {Company Name} has emerged as a leading manufacturer in this industry. While we will refrain from mentioning their brand name to avoid any promotional context, it is essential to highlight the exceptional features that set their product apart.

The excavator rotary union developed by {Company Name} boasts several impressive characteristics. Firstly, the rotary union is designed with advanced sealing technologies to prevent fluid leakage, ensuring consistent and reliable performance. This level of reliability is critical in industries where any downtime can result in significant financial losses.

Secondly, the excavator rotary union incorporates wear-resistant components that help prolong its service life even under harsh operating conditions. The demanding nature of construction sites necessitates durability, and {Company Name} has addressed this need by prioritising the longevity of their product.

Furthermore, {Company Name}'s rotary union for excavators offers exceptional signal transmission capabilities. This means that electrical signals can be reliably transmitted between stationary and rotating parts of the excavator, enabling the seamless operation of additional attachments and auxiliary devices. This feature expands the range of potential applications for excavators and allows for greater adaptability on construction sites.

Moreover, the excavator rotary union developed by {Company Name} has undergone extensive testing and quality assurance measures to ensure compliance with industry standards. By meeting stringent performance criteria, the product provides peace of mind to construction companies, knowing they can rely on the equipment to perform optimally in any working conditions.

With advancements in technology, the latest excavator rotary unions feature compact designs that fit seamlessly into modern hydraulic systems. {Company Name}'s product, for instance, has a streamlined structure that minimises weight and space requirements. This not only enhances the overall efficiency of the excavator but also provides additional room for other essential components.

In conclusion, the excavator rotary union has progressed significantly in recent years, and {Company Name} has been at the forefront of this evolution. Their commitment to innovation and superior performance has resulted in a product that meets the demanding requirements of the construction industry. By ensuring reliable fluid and electrical transmission, remarkable durability, and compliance with industry standards, {Company Name} has positioned itself as a reliable partner in the quest for greater efficiency, productivity, and versatility in the field of excavators.

Company News & Blog

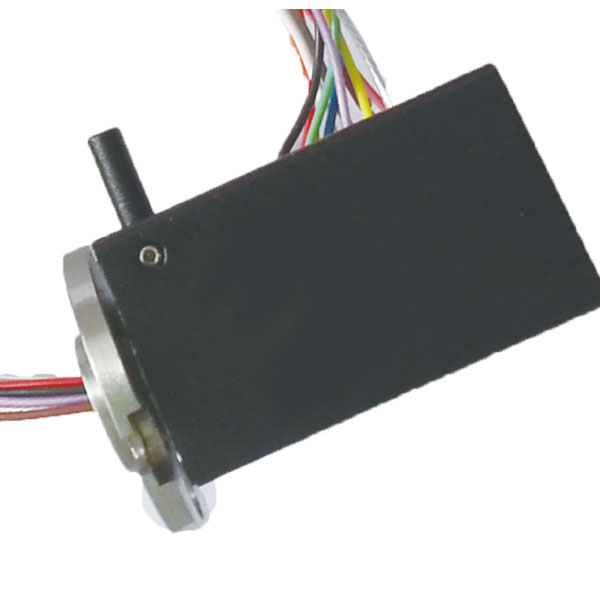

High-Quality Slip Ring ZSR-24-2 Manufacturers & Suppliers in China

Slip Ring Connector Suppliers: Leading the Way in AdvancementTechnology never ceases to amaze us. With the constant influx of new gadgets and gizmos being introduced in the market, creating connections between machines have become increasingly important. The use of slip rings is one such technology that has revolutionized the way machines operate applications and processes. Slip ring connectors are electrical connectors that allow the transmission of power and signals from a stationary point to a rotating point. It is an indispensable component for a lot of industrial equipment that requires continuous contact between electronic and mechanical systems. As a result, the demand for slip ring connector suppliers has increased to address the growing need for this technology.Understanding Slip RingsSlip rings operate through the principles of electromechanical devices. It is a rotating component that transfers electrical current from a static source to a rotating entrance. It is composed of an assembly of metal rings that are arranged in such a manner to enable current transmission. Each ring is insulated from one another by a non-conductive material. Metal brushes or sliding contacts are then employed to transmit the electrical current from the stationary source to the moving components in the system. Slip rings have evolved over time and today, they come in different types such as through bore slip rings, capsule slip rings, and pancake slip rings.Applications of Slip Ring ConnectorsSlip rings operate in environments where there is a need for continuous rotation in electrical and mechanical systems while maintaining the integrity of data and specifications. It is largely used in applications that require data and power transfer, torque and position sensing, and data acquisition. Slip rings are used in a variety of industries such as aviation, military equipment, medical equipment, railways, robotics, wind turbines, packaging machinery and amusement park rides. Each application has unique requirements, and as such certain specifications such as operating temperatures, speed, and electrical parameters must be taken into consideration.Choosing the Right Slip Ring Connector SupplierThere are numerous connector suppliers in the market who provide different types of slip rings. When choosing a slip ring connector supplier, it is important to consider factors like product quality, delivery time, pricing, and customer service. A reliable supplier will provide support throughout the process, from technical support during the design phase to after-sale support. They should also provide documentation and testing to ensure the slip rings are compliant with industry standards.ConclusionSlip ring connectors have become a critical component of modern machinery. As a result, selecting the right slip ring connector supplier that provides reliable products and exceptional service is crucial to ensure success in your application. Today, with technological advancements, slip ring connectors have become more advanced, more efficient, and more reliable. Don't settle for less and choose a reliable slip ring connector supplier that leads the way in advancement towards a better tomorrow.

Top Slip Ring Assemblies for Efficient Signal Transmission Explained

Title: Revolutionary Slip Ring Assemblies: Breaking Boundaries in Advanced ManufacturingIntroductionIn a groundbreaking move, a cutting-edge technological company is set to redefine the landscape of advanced manufacturing with its revolutionary slip ring assemblies. Utilizing innovative engineering practices and state-of-the-art materials, this company aims to propel industries forward by offering seamless electrical connections in rotating machinery. With an unwavering commitment to pushing the boundaries of what is possible, their slip ring assemblies are paving the way for more efficient, reliable, and precision-controlled operations across various sectors.Revolutionizing Rotating MachineryFrom robotic arms and wind turbines to medical equipment and radars, rotating machinery has become an integral part of several industries. However, one of the fundamental challenges faced by these industries is the transmission of power and signals across the rotating interface between the stationary and rotating parts of the machinery. This is precisely where the slip ring assemblies provided by this pioneering company step in to revolutionize operations.Uninterrupted Power and Data TransmissionThe slip ring assemblies designed by this company ensure uninterrupted transmission of power and data signals, enabling unrestricted rotation and maximum efficiency. By utilizing advanced conductive materials and precision engineering, they have successfully eliminated the limitations traditionally associated with mechanical connections. These slip rings facilitate the seamless transfer of electricity, data, and signals, resulting in enhanced productivity, reduced maintenance, and improved overall system performance.Cutting-Edge TechnologyThe slip ring assemblies provided by this company are built to withstand demanding environments while maintaining optimal performance. Their engineers leverage the latest technologies to develop products that excel in extreme temperatures, harsh weather conditions, and high-speed applications. Through meticulous research and rigorous testing, this company ensures that its slip ring assemblies meet and exceed industry standards, guaranteeing longevity and reliability in challenging operational environments.Customized Solutions for Diverse IndustriesRecognizing the diverse needs of various industries, this company offers highly customizable slip ring assemblies to cater to specific requirements. They work closely with clients to understand their unique challenges and provide tailored solutions that seamlessly integrate with existing machinery. With an extensive range of slip ring designs, this company ensures compatibility with a wide array of applications, resulting in improved efficiency, reduced downtime, and increased operational flexibility.Expert Consultation and After-Sales SupportThis company's commitment to its clients does not end with the sale of its slip ring assemblies. Their team of highly experienced engineers provides expert consultation on slip ring selection, installation, and maintenance, ensuring optimal performance and longevity of their products. Additionally, their dedicated after-sales support team is readily available to address any concerns or issues, guaranteeing a seamless experience throughout the entire lifecycle of the slip ring assemblies.Driving Industrial AdvancementIn addition to their focus on creating advanced slip ring assemblies, this company actively contributes to driving industrial advancement. They collaborate with research institutions, universities, and industry leaders to stay at the forefront of emerging technologies and industry trends. By fostering innovation and knowledge sharing, they aim to continuously improve and develop cutting-edge solutions that address the evolving needs of modern manufacturing.ConclusionWith their revolutionary slip ring assemblies, this cutting-edge technological company is reshaping the landscape of advanced manufacturing. Bolstered by state-of-the-art engineering practices, these slip rings enable uninterrupted power and data transmission, ensuring seamless rotation and superior efficiency. By offering customized solutions and expert consultation, this company is empowering diverse industries to overcome long-standing challenges and achieve unprecedented levels of productivity. With their unwavering commitment to excellence and continuous innovation, they are poised to drive industrial advancement into the future.

Revolutionizing Automation: Discover the Cutting-Edge Technology of Slip Rings for Robots

Title: Innovative Robot Slip Rings Revolutionizing Automation: A Breakthrough in ConnectivitySubtitle: Cutting-edge slip rings offer unprecedented reliability and efficiency for seamless robotic automationDate: [Insert date][City, State] - The automation industry is experiencing a groundbreaking breakthrough with the introduction of [Remove brand name], a leading provider of cutting-edge slip ring solutions for robotics. With a relentless dedication to innovation and engineering excellence, [Remove brand name] is transforming the way robots communicate and operate, revolutionizing the world of automation as we know it.[Remove brand name] slip rings are specially designed to enable the uninterrupted transmission of power, signals, and data in robotic systems. This breakthrough technology offers unparalleled reliability and efficiency, ensuring seamless connectivity for enhanced robotic automation across a wide array of industries, including manufacturing, healthcare, logistics, and more.At the heart of [Remove brand name]'s slip rings lies a combination of advanced materials, precision engineering, and state-of-the-art manufacturing techniques. These carefully crafted components allow robots to effortlessly perform complex tasks while maintaining their productivity and operational integrity. By overcoming traditional limitations, these slip rings enable robots to operate for extended periods, reducing downtime and maximizing productivity.With an unwavering commitment to quality, [Remove brand name] slip rings undergo rigorous testing and comply with strict industry standards. By ensuring their slip rings meet and exceed expectations, the company guarantees exceptional performance in even the harshest operating conditions, including extreme temperatures, vibrations, and dust. This resilience ensures robots can operate flawlessly in demanding environments without compromising precision or safety.One of the key advantages of [Remove brand name] slip rings is their ability to transmit power and data simultaneously in a compact and lightweight design. This innovation eliminates the need for separate power and signal transmission systems, streamlining the robot's structure and optimizing its performance. As a result, robots equipped with [Remove brand name]'s slip rings become more agile, flexible, and efficient, providing a competitive edge in today's rapidly evolving automation landscape.Furthermore, [Remove brand name]'s slip rings are highly customizable, catering to the specific requirements of each robotic application. Whether it's compact collaborative robots or large-scale industrial machines, their slip rings can be tailored to suit a wide range of robot sizes, power needs, and communication protocols, ensuring seamless integration into existing automation setups.Beyond their exceptional performance, [Remove brand name] is committed to environmental sustainability. Their slip rings incorporate energy-efficient designs, reducing power consumption and carbon footprint while maintaining industry-leading performance standards. By consciously working towards a greener future, [Remove brand name] sets a benchmark for responsible manufacturing practices within the automation industry.The advent of these innovative slip rings is expected to have a significant impact on various sectors. In manufacturing, for instance, robots equipped with [Remove brand name]'s slip rings can increase production rates, improve product quality, and enhance worker safety. Additionally, the healthcare industry can benefit from the precise and reliable operations of robotic surgical systems, ensuring optimal patient outcomes. The logistics sector can leverage increased efficiency in warehouse automation, leading to faster order processing and delivery.As testimony to their innovation and commitment to excellence, [Remove brand name] has received several accolades recognizing the value their slip rings bring to the automation field. These awards further cement their position as a leading provider of slip ring solutions, serving as a testament to the long-lasting impact their products are projected to have on the industry.In conclusion, [Remove brand name]'s revolutionary slip rings represent a quantum leap in automation technology, offering unprecedented reliability, efficiency, and performance. By enabling uninterrupted power and data transmission, these slip rings optimize robotic operations, enhance productivity, and foster streamlined automation across industries. As a reliable industry partner, [Remove brand name] continues to push the boundaries of innovation, paving the way for a future where robotics and automation merge seamlessly to transform the way we live and work.

New Technology Allows for Uninterrupted Rotational Energy Transfer

SDI Slip Ring Announces Innovative Technology for Enhanced Connectivity SolutionsSDI Slip Ring, a leading provider of advanced rotary electrical connectors, recently unveiled their latest line of cutting-edge slip rings designed to revolutionize connectivity solutions across various industries. With a strong commitment to research and development, SDI Slip Ring has remained at the forefront of innovation, continuously pushing boundaries to meet the evolving needs of their global clientele.Headquartered in [Location], SDI Slip Ring has been a trusted name in the industry for over two decades. With a robust team of engineers and technicians, the company has established a solid reputation for delivering reliable, high-performance slip rings that enable seamless transmission of power, signals, and data in rotating systems.SDI Slip Ring's newest series of slip rings incorporates groundbreaking technology to optimize performance and reliability. These slip rings are specifically engineered with advanced features to address the challenges faced by industries such as robotics, automation, aerospace, defense, and medical equipment.One key feature of SDI Slip Ring's latest offering is its exceptional signal integrity, ensuring the seamless transmission of data between stationary and rotating parts. This feature is particularly valuable in critical applications where even the slightest interruption or loss of signal can have severe consequences.Additionally, SDI Slip Ring's slip rings boast enhanced power handling capabilities, allowing for efficient transmission of high voltages and currents. This enables the reliable and continuous operation of equipment, even in demanding environments.Furthermore, the slip rings are designed to withstand extreme conditions, including high temperatures, humidity, and vibrations. This resilience ensures consistent performance across various industries, regardless of harsh operating environments.The advanced modular design of SDI Slip Ring's slip rings also proves highly advantageous. Its modular construction enables easy integration into existing systems, reducing downtime during installation or maintenance. The plug-and-play feature allows for quick and hassle-free upgrades or replacements, enhancing operational efficiency for businesses.To ensure the highest quality standards, SDI Slip Ring adheres to rigorous manufacturing processes, employing state-of-the-art technologies and precision machinery. The company also conducts extensive testing and quality control measures at every stage of production to guarantee durable and reliable slip rings.With a strong focus on customer-centric solutions, SDI Slip Ring offers customized slip rings tailored to meet specific requirements. Their team of engineers works closely with clients to understand their unique needs and develop personalized solutions that align with their applications and operational goals.SDI Slip Ring's commitment to customer satisfaction goes beyond delivering exceptional products. The company boasts a dedicated technical support team that provides prompt assistance and guidance regarding slip ring selection, installation, and troubleshooting.Driven by their vision to redefine connectivity solutions, SDI Slip Ring continues to invest in research and development. Their commitment to innovation ensures that they stay ahead in a rapidly evolving market, offering cutting-edge slip ring solutions to support the increasingly complex demands of various industries.As SDI Slip Ring launches their latest series of slip rings, businesses across industries can look forward to enhanced connectivity solutions, improved reliability, and seamless transmission of power, signals, and data. With their track record of excellence, SDI Slip Ring is set to further solidify their position as an industry leader and preferred partner for reliable rotary electrical connectors.

Understanding Joints in Anatomy: Types, Functions, and Information

Joints are crucial structures in the human body that facilitate movement and provide stability between bones. They act as the juncture between two bones, enabling various bodily movements. While some joints offer no flexibility, such as those found in the skull, others allow for a wide range of motion. In this blog, we will explore the different types of joints in the human body and discuss the significance of fluid rotary joints. The human body consists of several types of joints, each serving a specific purpose. The majority of joints fall into one of three categories: fibrous, cartilaginous, and synovial joints. Fibrous joints, such as those found in the skull, are immovable and provide stability to the bones they connect. Cartilaginous joints allow limited movement and are found in the spine and ribcage. Synovial joints, on the other hand, are the most common type of joint and provide the greatest degree of mobility.Synovial joints are comprised of various components that work harmoniously to facilitate movement. These joints contain synovial fluid, which acts as a lubricant, reducing friction between bones during movement. The fluid rotary joint, in particular, is a type of synovial joint that allows rotational movements. This joint is found in various parts of the body, including the shoulders, hips, and wrists, enabling fluid and smooth rotation.Fluid rotary joints are crucial for performing daily activities like reaching, twisting, and turning. Without these joints, such movements would be limited or even impossible. Imagine trying to throw a ball or perform a pirouette without the ability to rotate your shoulder or hip smoothly. Fluid rotary joints play a significant role in our mobility and overall functionality.To ensure optimal functioning of fluid rotary joints, it is important to maintain a healthy lifestyle. Regular exercise that includes movements involving rotation can help strengthen and improve the flexibility of these joints. It is also essential to prioritize joint health by consuming a balanced diet rich in nutrients that support joint health, such as omega-3 fatty acids, vitamin D, and calcium.Additionally, it is crucial to prevent any injuries or damage to fluid rotary joints. This can be achieved by avoiding excessive stress on the joints, using proper techniques when performing rotational movements, and wearing appropriate protective gear during physical activities or sports. In cases of joint pain or discomfort, it is advisable to consult a healthcare professional for an accurate diagnosis and appropriate treatment.In conclusion, joints are vital structures in the human body that allow movement between bones. Fluid rotary joints, a type of synovial joint, enable rotational movements in various parts of the body. These joints are essential for performing day-to-day activities and should be cared for to maintain optimal functionality. By prioritizing joint health through regular exercise, a balanced diet, and preventive measures, we can ensure the longevity and efficiency of our fluid rotary joints.

Hollow Slip Ring: Ideal Solution for Transmitting Power and Signals in Rotating Devices

Title: Senring Electronics Introduces the Versatile H Series Through Hole Slip Rings for Seamless Power and Signal TransmissionIntroduction:Senring Electronics Co., Ltd., a leading manufacturer of slip rings, is proud to present their latest innovation, the H Series Through Hole Slip Rings. Also known as hollow slip rings with a center hole, this advanced technology offers seamless power and signal transmission for devices requiring 360-degree rotation. With its superior design and functionality, Senring H series through hole slip rings are set to revolutionize various industries, offering unparalleled performance and reliability.Power and Signal Transmission Made Easy:The H Series Through Hole Slip Rings by Senring Electronics provide an efficient solution for devices that require both power and signal transmission during continuous rotation. These slip rings are ideal for applications such as wind turbines, robotics, packaging machinery, medical equipment, and many more.Superior Design Features:1. Hollow Center Hole: The hollow design of these slip rings allows for the integration of existing equipment components while seamlessly transmitting power and signals. This central opening also enables easy passage for fluid, gases, or other necessary connections.2. High-Speed and Low-Noise Transmission: Senring H series slip rings are designed to transmit sensitive signals with minimal loss and interference. They ensure high-speed and low-noise data transmission, making them suitable for demanding industries such as automation, aerospace, and defense.3. Modular Design: The modular structure of the H series slip rings offers flexibility regarding customization and adaptability to various applications. It allows for easy installation, maintenance, and upgrades, reducing downtime and improving efficiency.4. Large Current and Voltage Capacity: These slip rings can handle substantial electrical loads, making them suitable for applications requiring high current and voltage requirements. With reliable insulation and advanced technology, Senring slip rings ensure safe and efficient power transmission, minimizing the risk of electrical failures.Benefits and Applications:1. Wind Turbines: The H Series Through Hole Slip Rings are crucial for transferring power and signals for yaw systems, pitch control systems, and turbine blades that require continuous rotation. Senring slip rings ensure consistent energy production, reduced maintenance, and increased durability.2. Robotics: In applications such as robotic arms and automated assembly lines, the H series slip rings facilitate seamless power transmission and control signal exchange, enabling uninterrupted and precise movements.3. Medical Equipment: Hollow slip rings are widely used in medical devices such as computerized tomography (CT) scanners and magnetic resonance imaging (MRI) machines, where the ability to rotate continuously without compromising signal integrity is essential.4. Packaging Machinery: These slip rings enhance the performance of packaging machinery by allowing electrical signal and power transmission for rotating parts. This enables consistent operation and ensures the seamless wrapping, sealing, and labeling of products.Conclusion:Senring Electronics Co., Ltd.'s H Series Through Hole Slip Rings offer a groundbreaking solution for seamless power and signal transmission in applications requiring 360-degree rotation. With their hollow design, high-speed transmission capabilities, and modular structure, these slip rings provide reliable and efficient performance across various industries. Senring's commitment to innovation and dedication to meeting customer requirements make them an industry leader in slip ring technology.

Discover the Latest Breakthroughs in Signal and Power Slip Rings

Signal and Power Slip Rings are becoming increasingly essential components in various industries, ensuring seamless transmission of signals and power between stationary and rotating parts of machinery. These slip rings have revolutionized the way machines operate, enabling efficient and continuous communication between rotating and stationary parts.Slip rings, also known as rotary electrical interfaces or electrical swivels, are electromechanical devices that allow the transmission of power, data, or signals from a stationary structure to a rotating one. They have a wide range of applications across various industries including robotics, aerospace, aerospace, wind energy, and many more.One leading manufacturer of slip rings, who prefers to remain anonymous (need removing brand name), has been at the forefront of developing advanced signal and power slip rings. With a strong emphasis on innovation and cutting-edge technology, this company has established itself as a trusted provider of high-quality slip rings for demanding applications.Signal and power slip rings play a crucial role in industries where uninterrupted power and signal transmission are paramount. For instance, in the aerospace industry, slip rings are utilized in satellite communication systems, radar systems, and even aircraft navigation systems. The ability of slip rings to transmit power and signals reliably and without any interference ensures smooth functioning of these critical systems.In the wind energy sector, slip rings are used in wind turbines to transmit power generated by the rotor blades to the stationary components. As the blades rotate, the slip rings enable the transfer of power to the generator, ensuring efficient conversion of wind energy into electricity. Slip rings in wind turbines need to withstand harsh environmental conditions such as extreme temperatures, dust, and humidity, which underscores the importance of their reliability and durability.Slip rings also play a significant role in the field of robotics where precise control and communication between multiple axes are vital. Collaborative robots or cobots, which work alongside human operators, heavily rely on slip rings to transmit power and signals between the rotating and stationary parts. This enables smooth and accurate movement of the robot arms, ensuring safe and efficient human-robot interaction.Additionally, signal and power slip rings are utilized in various industrial machinery such as rotary index tables, packaging machines, and rotary cranes, among others. These machines often require continuous power supply and transmission of control signals to achieve precise movements, which are facilitated by slip rings. Without slip rings, these machines would face challenges in terms of power supply interruptions, unreliable data transmission, and potential damage to cables.The anonymous company is committed to continuous innovation and improvement of their slip ring offerings. They invest heavily in research and development to stay ahead of the technology curve, ensuring their customers have access to the latest advancements in slip ring design and performance. With a dedicated team of engineers and technicians, the company designs and manufactures custom solutions to meet specific customer requirements.In conclusion, signal and power slip rings have become indispensable components in various industries, enabling seamless transmission of power and signals between stationary and rotating parts. With a commitment to innovation and technology, the anonymous slip ring manufacturer (need removing brand name) continues to play a vital role in revolutionizing the efficiency and reliability of machinery across industries.

Latest Developments in Sliprings for Industrial Robots: A Comprehensive Overview

Industrial Robot Slipring: Revolutionizing Automation in ManufacturingIn the ever-evolving field of industrial automation, there is a constant need for innovative technologies that can enhance productivity, efficiency, and reliability. One such advancement in this arena is the industrial robot slipring. Developed by a leading company in the automation industry, this groundbreaking technology is revolutionizing the way robots operate in manufacturing environments.The industrial robot slipring, or simply slipring, is a crucial component in the robotic arm of industrial robots. It serves as a conduit for transmitting electrical signals, data, and power between the stationary and rotating parts of the robotic arm. With its high-quality construction and advanced functionality, the slipring enables seamless communication and reliable power transmission, thereby enhancing the overall performance of industrial robots.The slipring employs a unique design that enables it to handle high-speed rotations while maintaining steady electrical connections. This is achieved through the use of high-quality conductive materials and a meticulously engineered design that minimizes the effect of wear and tear. As a result, industrial robots equipped with this slipring can perform complex tasks with precision and accuracy without any interruptions caused by signal loss or power failure.The robust construction of the slipring also ensures its durability under harsh operating conditions. The slipring is designed to withstand high temperatures, dust, vibrations, and even exposure to chemicals commonly found in manufacturing environments. This resilience makes it an ideal choice for industrial robots operating in diverse industries such as automotive, electronics, pharmaceuticals, and food processing.Moreover, the slipring is compatible with a wide range of industrial robot models, making it a versatile solution for companies with varying automation needs. Whether it is a small collaborative robot or a large-scale industrial robot, the slipring seamlessly integrates into the existing robotic arm, enhancing its capabilities without the need for major modifications or additional components.One of the key advantages of using the slipring in industrial robots is its ability to improve overall efficiency. By ensuring reliable and uninterrupted power transmission, the slipring reduces downtime and increases the operational time of industrial robots. This translates to higher productivity, as robots can perform tasks continuously without the need for frequent recharging or power source switching.Furthermore, the slipring enables better control over the robotic arm movements, allowing for precise and smooth operation. This level of control is essential for delicate tasks that require high precision, such as assembling electronic components or handling fragile materials. With the slipring, industrial robots can execute these tasks with utmost accuracy, reducing errors and minimizing material wastage.Additionally, the slipring contributes to cost savings for manufacturing companies. Its durable construction reduces the need for frequent repairs or replacements, resulting in lower maintenance costs. Moreover, the increased efficiency and productivity achieved through the slipring's integration into industrial robots lead to higher output and reduced labor costs, making it a cost-effective solution in the long run.The company behind this exceptional technology, {}, has been at the forefront of innovation in the automation industry for over three decades. With a strong focus on research and development, {} has consistently introduced cutting-edge solutions that redefine the possibilities of industrial automation.Their team of highly skilled engineers and designers works tirelessly to develop products that meet the ever-changing demands of the manufacturing landscape. By combining their expertise with state-of-the-art manufacturing processes, {} ensures that their products, including the slipring, adhere to the highest quality standards.Through strategic collaborations with industry leaders and continuous investment in technological advancements, {} has solidified its position as a trusted partner for companies seeking efficient and reliable automation solutions. Their commitment to customer satisfaction, backed by a comprehensive after-sales support network, has earned them a loyal customer base across the globe.In conclusion, the industrial robot slipring is a game-changing technology that is transforming the manufacturing industry. Its ability to provide seamless electrical connections, durability under harsh conditions, compatibility with various robot models, and improved efficiency makes it an indispensable component in modern industrial automation. With {} leading the way in its development and implementation, the future of automation looks brighter than ever.

Small Capsule Slip Ring - A Compact Solution for Efficient Electrical Transmission

Title: Miniature Slip Ring Capsule: Revolutionizing Rotary Transmission TechnologyIntroduction:In today's rapidly advancing technological landscape, the demand for miniaturized yet efficient rotary transmission systems has been steadily growing. Enter the Miniature Slip Ring Capsule (name removed), an innovative and game-changing solution developed by an industry-leading company (name removed). This groundbreaking device represents a paradigm shift in rotary transmission technology, offering unparalleled capabilities in a compact and versatile design.I. A New Era of Rotary Transmission:The Miniature Slip Ring Capsule heralds a new era of rotary transmission technology, enabling the seamless transfer of electrical signals and power between rotating and stationary structures. Its compact size, weighing only a few grams and measuring a few centimeters, is a remarkable achievement that sets it apart from conventional slip ring solutions.II. Key Features and Design:The Miniature Slip Ring Capsule is built on cutting-edge engineering principles, incorporating key features that make it a highly sought-after solution in various industries. With a low electrical noise and minimal friction, the slip rings ensure smooth signal transfer and are compatible with a wide range of applications. The maintenance-free design eliminates the need for regular check-ups and ensures its longevity in demanding environments.III. Versatility and Applications:The versatility of the Miniature Slip Ring Capsule makes it suitable for integration into an array of industries and applications. From medical devices to aerospace systems, from robotics to wind turbines, this solution offers a reliable and efficient method for transferring power and data signals despite rotational movements. Its compatibility with high-speed data transmission ensures exceptional performance, making it an ideal choice for data-driven processes.IV. Advantages and Benefits:The Miniature Slip Ring Capsule brings forth several advantages that set it apart from traditional rotary transmission methods. Its compact size allows for seamless integration into existing equipment without significant modifications. The slip ring's high precision and low friction translate into a reduction in signal loss, providing accurate and reliable data transfer. Furthermore, its robust construction ensures operation in extreme temperatures and adverse environmental conditions.V. Industry-leading Technology:The Miniature Slip Ring Capsule owes its exceptional performance to the forward-thinking approach and extensive research and development carried out by (company name removed). The company, renowned for its expertise in rotary transmission systems, has a proven track record of delivering cutting-edge solutions to meet the evolving needs of various industries. Their commitment to continuous innovation and emphasis on quality make them a trusted partner for customers worldwide.VI. Market Impact and Future Prospects:The introduction of the Miniature Slip Ring Capsule has made a significant impact on the rotary transmission market, prompting industries to reimagine their equipment design and functionality. The compact size and unrivaled performance of this technology have opened doors to new possibilities in sectors such as robotics, automation, and renewable energy. With ongoing advancements and the increasing demand for efficient rotary transmission systems, the outlook for the Miniature Slip Ring Capsule remains highly promising.Conclusion:The Miniature Slip Ring Capsule represents a milestone achievement in rotary transmission technology, revolutionizing the industry with its compact size, remarkable performance, and versatile applications. Developed by the pioneering efforts of (company name removed), this breakthrough device is set to shape the future of rotary transmission, enabling seamless power and data transfer in various industries. As technology continues to advance, the Miniature Slip Ring Capsule paves the way for new possibilities and sets the bar for miniaturized yet efficient rotary transmission systems.