High-Quality Carbon Brush With Holder for Industrial Machinery

By:Admin

The carbon brush with holder is designed to provide a reliable and efficient electrical connection between moving and stationary parts in motors, generators, and other types of electrical machinery. It is made from high-quality carbon materials, which are known for their excellent electrical conductivity and resistance to wear and tear. The addition of the holder ensures easy installation and replacement, making maintenance of the electrical equipment a breeze.

This new product is the result of years of research and development by the company. Their team of experienced engineers and technicians have worked tirelessly to create a carbon brush with holder that meets the highest standards of quality and performance. Through extensive testing and refinement, they have achieved a product that not only exceeds industry standards but also provides a cost-effective solution for their customers.

The introduction of this carbon brush with holder is a testament to the company's commitment to innovation and excellence. They have always been at the forefront of technological advancements in the industry, constantly pushing the boundaries of what is possible. By staying ahead of the curve, they have earned a reputation as a trusted and reliable partner for companies in need of high-quality electrical components.

One of the key advantages of the carbon brush with holder is its ability to improve the overall efficiency of electrical equipment. By providing a stable and consistent electrical connection, it reduces the risk of power loss and downtime. This, in turn, can lead to increased productivity and cost savings for companies that rely on their electrical machinery to drive their operations.

Furthermore, the durability of the carbon brush with holder ensures a longer lifespan for the electrical equipment. With less frequent replacements and maintenance, companies can save on both time and resources, ultimately leading to a higher return on investment. This is particularly beneficial for industries that rely heavily on their electrical machinery to keep their operations running smoothly.

The carbon brush with holder is also designed with sustainability in mind. The use of high-quality carbon materials not only ensures excellent performance but also minimizes the environmental impact of the product. As companies strive to make their operations more sustainable, this new product provides a viable option for reducing their carbon footprint.

With the introduction of the carbon brush with holder, the company has once again proven its commitment to delivering innovative solutions to the industry. This product has the potential to revolutionize the way electrical equipment is designed and maintained, offering a level of performance and reliability that was previously unattainable.

As companies across various industries continue to seek ways to improve the efficiency and sustainability of their operations, the carbon brush with holder could very well become a staple component in their electrical machinery. With its proven performance and cost-effective nature, this product is set to make a significant impact on the industry for years to come.

Company News & Blog

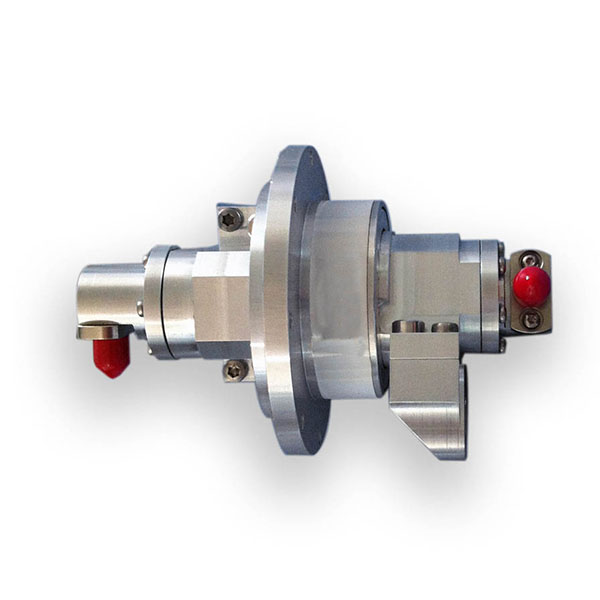

High-Quality Coaxial Rotary Joints for Reliable Signal Transmission

The world of technology is constantly evolving, and new innovations are constantly being developed to push the boundaries of what is possible. One such innovation is the 1 Ch Coaxial Rotary Joint, a cutting-edge technology that is set to revolutionize the way we think about rotary joints. This new development has the potential to greatly impact a wide range of industries, from telecommunications to aerospace, and beyond.The 1 Ch Coaxial Rotary Joint is a compact and efficient solution for transmitting high-frequency signals in a rotating system. It is designed to provide a reliable and continuous connection between stationary and rotating parts, making it an ideal choice for a variety of applications. Whether it be for radar systems, satellite communication, or medical imaging equipment, the 1 Ch Coaxial Rotary Joint offers unparalleled performance and reliability.The company behind this groundbreaking technology, {}, is a leading provider of RF and microwave components for the global market. With a strong focus on research and development, the company has a long history of delivering innovative solutions to meet the ever-growing demands of the industry. The 1 Ch Coaxial Rotary Joint is the latest addition to their extensive portfolio of products, and it is set to further solidify their position as a trusted partner for high-frequency solutions.In addition to its impressive technical capabilities, the 1 Ch Coaxial Rotary Joint also boasts a number of key features that set it apart from other similar products on the market. Its compact and lightweight design makes it easy to integrate into existing systems, while its high-speed capabilities ensure seamless and uninterrupted signal transmission. Furthermore, it is built to withstand the harshest environmental conditions, making it a versatile solution for a wide range of applications.The development of the 1 Ch Coaxial Rotary Joint is a testament to the company's commitment to advancing the field of RF and microwave technology. By investing in cutting-edge research and development, they have been able to push the boundaries of what is possible, resulting in the creation of a product that is truly ahead of its time. As the demand for high-frequency solutions continues to grow, the 1 Ch Coaxial Rotary Joint is poised to make a significant impact on the industry.The potential applications of the 1 Ch Coaxial Rotary Joint are vast and varied, with its capabilities reaching far beyond what is currently possible with existing technology. From military and defense systems to medical imaging and telecommunications, the possibilities are endless. This new development has the potential to greatly impact a wide range of industries, from telecommunications to aerospace, and beyond. The possibilities are vast and varied, with its capabilities reaching far beyond what is currently possible with existing technology.As the industry continues to evolve, the demand for reliable and high-performance rotary joints will only continue to grow. With the introduction of the 1 Ch Coaxial Rotary Joint, {}, has proven once again that they are at the forefront of the industry, consistently delivering innovative solutions that push the boundaries of what is possible. As the world of technology continues to advance, the 1 Ch Coaxial Rotary Joint is set to play a key role in shaping the future of high-frequency signal transmission.

Discover the Revolutionary Advancements of Embedded High Speed Slip Rings

Title: Revolutionary Embedded High-Speed Slip Rings: Pioneering Breakthroughs in Power and Data TransmissionIntroduction and Company Overview:Innovation and technological advancements continue to redefine the way machines and systems function across various industries. Among these advancements, the development of Embedded High-Speed Slip Rings has emerged as a promising breakthrough in power and data transmission. This article will delve into the incredible potential of these slip rings while keeping the company's identity anonymous.With extensive experience in the field, our featured company has garnered a reputation for its cutting-edge engineering solutions. As leaders in slip ring technology, they have recently introduced their groundbreaking Embedded High-Speed Slip Rings, marking a significant step forward in the field.1. The Emergence of Embedded High-Speed Slip Rings:Embedded High-Speed Slip Rings have emerged as indispensable components for machines and systems requiring continuous rotation while transmitting power and data signals. These slip rings facilitate seamless transmission, ensuring optimum performance and efficiency across a spectrum of industries.2. Advantages and Features:Embedded High-Speed Slip Rings offer a multitude of advantages that set them apart from traditional slip rings. Here are some notable features:a) Compact Design: The embedded design ensures a compact form factor, making them highly suitable for applications with limited space.b) Enhanced Signal Integrity: These slip rings excel at maintaining signal integrity, enabling high-quality data transmission without loss or interference.c) High Rotational Speed: Designed to accommodate high rotational speeds, these slip rings maintain exceptional performance, even under demanding conditions.d) Low Electrical Noise: Advanced insulation and grounding techniques significantly reduce electrical noise, ensuring clean and reliable data and power transmission.e) Longevity and Durability: Employing high-quality materials combined with excellent engineering, these slip rings are designed to withstand rigorous working environments, providing long-lasting and reliable operation.3. Industrial Applications:Embedded High-Speed Slip Rings find applications in various industries, revolutionizing power and data transmission across critical applications. The following sectors substantially benefit from their advanced capabilities:a) Robotics and Automation: In fields like industrial automation and robotics, high-speed rotational movement combined with reliable and uninterrupted power and data transmission is crucial. Embedded High-Speed Slip Rings help maintain the performance and integrity of these systems.b) Medical Equipment: Medical devices require precision, reliability, and seamless communication between various components. Embedded High-Speed Slip Rings ensure uninterrupted power supply and continuous data transmission for diagnostic imaging equipment, robotic surgical systems, and more.c) Defense and Aerospace: The defense and aerospace sectors often rely on slip rings in systems such as communication antennas, radar systems, and missile launchers. Embedded High-Speed Slip Rings enhance communication accuracy and efficiency, playing a vital role in these critical applications.d) Wind Turbines: In the renewable energy sector, slip rings are used in wind turbines to transfer electrical power from the rotating blades to the stationary circuitry. Embedded High-Speed Slip Rings guarantee efficient power transmission, contributing to optimal energy generation.e) Broadcasting and Communication: Media equipment, such as rotating cameras and specialized broadcasting equipment, necessitate reliable transmission of power and uninterrupted data connectivity. Embedded High-Speed Slip Rings ensure continuous and high-speed signal transmission, facilitating smooth broadcasting operations.4. Conclusion:Embedded High-Speed Slip Rings have revolutionized the mechanism by which power and data are transferred in various industries. With advancements in technology and continual innovation, these slip rings contribute immensely to increased efficiency, improved performance, and seamless connectivity.As the demand for high-speed, reliable, and durable slip rings grows, companies like our featured partner remain at the forefront of engineering extraordinary solutions. Their Embedded High-Speed Slip Rings exemplify the industry's commitment to pushing boundaries and creating the foundations for a technologically advanced future.

High-Quality Slip Ring Manufacturer in China - Latest News

China Slip Ring Company is a leading manufacturer of high-quality slip rings and rotary joints for various industries. With their extensive experience and advanced technology, the company has been providing reliable and efficient solutions for transmitting power and data in rotating machinery for over a decade.The company's comprehensive product line includes standard slip rings, custom-designed slip rings, and rotary joints that are suitable for a wide range of applications, including aerospace, defense, medical equipment, packaging machinery, and more. Their products are known for their high performance, long service life, and robust design, making them the ideal choice for demanding industrial environments.In addition to their standard products, China Slip Ring Company also offers custom solutions to meet specific customer requirements. Their team of experienced engineers and technicians work closely with clients to develop tailored slip ring and rotary joint solutions that perfectly fit their needs. Whether it's a complex integration project or a simple modification, the company is committed to delivering innovative and reliable products that exceed customer expectations.With a strong focus on research and development, China Slip Ring Company continuously strives to improve their products and explore new technologies. Their state-of-the-art manufacturing facilities and strict quality control processes ensure that every product meets the highest standards of performance and reliability. This dedication to excellence has earned the company a reputation as a trusted and preferred supplier in the industry.In addition to their product excellence, China Slip Ring Company places great emphasis on customer satisfaction and after-sales support. Their knowledgeable sales team and technical experts provide professional advice and assistance to help clients find the best solutions for their applications. Moreover, the company offers comprehensive technical documentation, installation guides, and maintenance services to ensure seamless integration and trouble-free operation of their products.Furthermore, China Slip Ring Company is committed to sustainability and environmental responsibility. They adhere to strict environmental regulations and standards in their manufacturing processes, and constantly seek ways to minimize their ecological footprint. By using recyclable materials, reducing energy consumption, and implementing eco-friendly practices, the company aims to contribute to a cleaner and greener world.As China Slip Ring Company continues to expand its presence in the global market, they remain dedicated to upholding their core values of innovation, quality, and customer satisfaction. Their relentless pursuit of excellence and commitment to delivering reliable products have earned them the trust and confidence of their customers worldwide.In conclusion, China Slip Ring Company's extensive product range, custom solutions, commitment to innovation, and dedication to customer satisfaction make them a reliable and preferred partner for slip rings and rotary joints. With their unwavering focus on quality and continuous improvement, the company is well positioned to meet the evolving needs of various industries and maintain their leadership in the market.

Understanding the Purpose and Function of Slip Rings in Various Industries

Title: Understanding Slip Rings: The Unsung Heroes of Electrical ConnectionsIntroduction:In the realm of modern technology, where efficiency, precision, and seamless operations are paramount, slip rings play a critical yet often overlooked role. Serving as the unsung heroes behind smooth electrical connections in various applications, slip rings enable the transmission of power, signals, and data between rotating and stationary parts of a system. This article aims to shed light on the essential nature of slip rings, their diverse applications, and the innovations brought forth by a prominent industry leader {}.1. Understanding Slip Rings:Slip rings, also known as rotary electrical interfaces, are electromechanical devices engineered to transmit electrical power and signals from a stationary to a rotating structure. They allow continuous rotation without the hassle of entangling wires, ensuring uninterrupted functioning of various equipment and machinery.At its core, a slip ring consists of three vital components: rings, brushes, and a housing. The rings are made of metal or other conductive materials and are mounted on a shaft or assembly, rotating with the machine. The brushes, typically made of graphite or other conductive materials, make contact with the rings, enabling the transfer of electricity or signals. Finally, the housing encloses the rings and brushes, providing protection from environmental factors such as dust, moisture, and vibrations.2. Diverse Applications of Slip Rings:2.1 Aerospace and Defense:Slip rings are extensively used in aerospace and defense applications, where reliability and precision are paramount. They facilitate communication and power transmission in radar systems, satcom antennas, surveillance systems, missile guidance, and weapon systems, among others. Slip rings, designed to withstand harsh environments and extreme temperatures, ensure unhindered operation during critical missions.2.2 Wind Turbines:In the realm of renewable energy, slip rings play a crucial part in the propelling mechanism of wind turbines. They enable the continuous rotation of the blades while transmitting power generated by the rotor to the stationary parts of the turbine. Slip rings in wind turbines are engineered to withstand high-speed rotation, extreme weather conditions, and constant vibrations, ensuring efficient and reliable energy generation.2.3 Medical Equipment:In the healthcare sector, slip rings find applications in advanced medical imaging devices such as CT scanners, MRI machines, and X-ray systems. These devices require the transmission of high-quality images and precise data while allowing continuous rotation of the scanning elements. Slip rings provide the necessary electrical connections, making them an invaluable component in ensuring accurate diagnoses and effective patient care.2.4 Industrial Machinery:From heavy machinery to robotic arms, slip rings are crucial in various industrial applications. They facilitate continuous rotation in cranes, packaging machines, welding robots, assembly lines, and more. By providing uninterrupted electrical connections, slip rings enhance the efficiency, productivity, and safety levels of industrial machinery, minimizing downtime and optimizing output.3. Innovations by a Prominent Industry Leader {}:With a commitment to precision engineering and technological advancements, {} has emerged as a prominent player in the slip ring industry. Their innovative approach and cutting-edge solutions have helped redefine the capabilities of slip rings, ensuring optimal performance across diverse sectors.{}'s slip rings are known for their impeccable engineering, robust construction, and ability to withstand the toughest environments. Utilizing advanced materials such as precious metals and specialized coatings, their slip rings offer superior signal quality, reduced friction, and extended operational life. Additionally, their customization options cater to specific industry requirements, further enhancing the adaptability and reliability of the slip rings.The integration of microelectromechanical systems (MEMS) technology and fiber optic transmission capabilities into their slip rings showcases {}'s commitment to pushing the boundaries of slip ring capabilities. These forward-thinking advancements ensure optimal performance and set the stage for future innovations in the field of electrical transmission.Conclusion:While often overshadowed by more familiar electrical components, slip rings play a pivotal role in the seamless transmission of power and signals in a wide range of industries. Their contributions to aerospace, defense, wind energy, medical equipment, and industrial machinery are invaluable. With innovative companies like {} driving advancements in slip ring technology, these crucial but lesser-known devices will continue to ensure reliable and efficient operations in our increasingly interconnected world.

Ultimate guide to integrated slip rings: Everything you need to know

Integrated Slip Ring, a cutting-edge technology developed by a leading engineering company, is revolutionizing the way signals and power are transmitted in rotary systems. This innovative solution allows for the seamless transfer of power and signals across rotating interfaces, making it ideal for a wide range of applications in industries such as aerospace, robotics, manufacturing, and more.The integrated slip ring technology is designed to address the challenges associated with traditional slip rings, which often require complex assembly and maintenance, and are prone to wear and tear over time. By integrating the slip ring directly into the rotating component, this new technology eliminates the need for external wiring and minimizes the risk of signal interference or power loss.One of the key features of the integrated slip ring is its compact and lightweight design, which allows for easy integration into existing rotary systems. This makes it an ideal solution for applications where space is limited or where weight restrictions are a concern. Additionally, the integrated slip ring offers increased reliability and durability, thanks to its robust construction and advanced materials.The company behind this groundbreaking technology has a long history of engineering excellence and innovation. With a team of highly skilled engineers and a state-of-the-art research and development facility, they have been at the forefront of developing cutting-edge solutions for the most demanding technological challenges.Founded in [year], the company has built a solid reputation for delivering high-quality engineering solutions to a diverse range of industries. Their commitment to innovation and continuous improvement has led to the development of several groundbreaking technologies, including the integrated slip ring, which has already garnered attention from industry leaders and experts.In addition to the integrated slip ring, the company offers a wide range of engineering solutions, including custom-designed rotary systems, precision motion control components, and advanced automation solutions. Their expertise in these areas has made them a trusted partner for many leading companies across various industries.The development of the integrated slip ring is a testament to the company's dedication to pushing the boundaries of what is possible in engineering. By addressing the limitations of traditional slip rings and offering a more reliable and efficient alternative, they have once again demonstrated their ability to deliver innovative solutions that meet the evolving needs of their customers.The integrated slip ring technology is already making waves in the industry, with several major companies expressing interest in integrating it into their rotary systems. Its potential to enhance the performance and reliability of a wide range of applications has positioned it as a game-changing technology that is set to revolutionize the way power and signals are transmitted in rotating systems.As the company continues to refine and expand the capabilities of the integrated slip ring, it is poised to further solidify its position as a leader in engineering innovation. With a strong track record of delivering cutting-edge solutions and a commitment to pushing the boundaries of what is possible, they are well-positioned to shape the future of rotary systems and beyond.In conclusion, the integrated slip ring technology developed by this leading engineering company represents a significant advancement in the field of rotary systems. Its compact design, reliability, and efficiency make it an ideal solution for a wide range of applications across various industries. As the company continues to innovate and push the boundaries of engineering, the integrated slip ring is set to become a staple technology in the world of rotating systems.

High-quality Slip Ring Shaft for Industrial Applications

Slip Ring Shaft: The Latest Innovation in Electrical Rotary JointsIn the world of electrical engineering, the need for rotary joints that can transmit power and signals while rotating continuously is essential. This is where slip ring shafts come into play, providing a reliable solution for such applications. One company that has been leading the way in this field is [Company Name].[Company Name] is a renowned manufacturer of slip ring shafts, with a long history of providing high-quality, innovative products to a wide range of industries, including aerospace, defense, and industrial machinery. The company's commitment to engineering excellence and continuous innovation has made it a trusted partner for many businesses around the world.The slip ring shaft is an essential component in many rotating electrical systems, including radar systems, wind turbines, and industrial machinery. It allows for the transfer of power and signals between stationary and rotating parts, enabling seamless operation of the equipment. The design and construction of slip ring shafts are crucial to their performance and durability, and [Company Name] has been at the forefront of developing cutting-edge solutions in this field.One of the key features of [Company Name]'s slip ring shafts is their reliability and longevity. The company uses advanced materials and manufacturing techniques to ensure that its products can withstand the harshest operating conditions. This reliability is critical in applications where downtime is not an option, such as in military equipment or industrial machinery.Furthermore, [Company Name] offers a range of customization options for its slip ring shafts, allowing its customers to tailor the products to their specific requirements. This flexibility has made the company a preferred supplier for many businesses looking for bespoke solutions to their rotary joint needs.In addition to its focus on product quality, [Company Name] places a strong emphasis on customer satisfaction. The company's team of engineers and technical support staff work closely with customers to understand their needs and provide the best possible solutions. This commitment to excellence has earned [Company Name] a reputation for outstanding customer service and support.The latest innovation from [Company Name] in the field of slip ring shafts is a new, advanced design that offers increased performance and reliability. This new product incorporates the latest technological advancements in materials and engineering, resulting in a superior solution for rotary joint applications. The company's engineers have worked tirelessly to ensure that the new slip ring shaft meets the highest standards of quality and performance, setting a new benchmark in the industry.With its unwavering dedication to innovation and customer satisfaction, [Company Name] continues to be a driving force in the evolution of slip ring shaft technology. The company's commitment to excellence and its ability to deliver cutting-edge solutions have firmly established it as a leader in the field of rotary joints.In conclusion, slip ring shafts are a critical component in many electrical systems, and [Company Name] has proven to be a top-tier provider of these essential products. With its focus on quality, customization, and customer satisfaction, the company has set itself apart as a trusted partner for businesses in need of reliable and high-performance rotary joints. The latest innovation in slip ring shaft technology from [Company Name] is a testament to the company's commitment to pushing the boundaries of what is possible in this field. As the demand for advanced rotary joint solutions continues to grow, [Company Name] is well-positioned to remain at the forefront of the industry.

Hassle-Free Slip Ring Refurbishment Services for All Industrial Machinery

In recent news, {Company Name}, a leading provider of advanced slip ring refurbishment services, has announced the successful completion of a major refurbishment project for Rov (Remotely Operated Vehicle) slip rings. The company’s expertise in slip ring technology and its commitment to delivering high-quality solutions have made it a trusted partner for a wide range of industries, including marine exploration, offshore drilling, and underwater research.{Company Name} specializes in the refurbishment of slip rings, which are critical components in Rov systems that allow for the transmission of power, signals, and data between the stationary and rotating parts of an underwater vehicle. Over time, these slip rings can experience wear and tear, leading to decreased performance and reliability. {Company Name}’s refurbishment process involves disassembling the slip ring, inspecting all components for damage or wear, replacing any worn or damaged parts, and reassembling the unit to like-new condition.The recent refurbishment project for Rov slip rings required {Company Name}’s team of engineers and technicians to work closely with the client to understand the specific requirements and performance expectations for the refurbished slip rings. This collaborative approach allowed {Company Name} to deliver a custom solution that met the client’s needs and exceeded their expectations.{Company Name}’s state-of-the-art facility is equipped with the latest tools and equipment, allowing for the precise refurbishment of slip rings of all sizes and configurations. The company’s team of experts has a deep understanding of the unique challenges and demands of Rov systems, and they are dedicated to delivering reliable and high-performance solutions to their clients.The successful completion of the Rov slip ring refurbishment project is a testament to {Company Name}’s commitment to excellence and innovation in the field of slip ring technology. The company’s track record of delivering superior quality refurbishment services has made it the go-to partner for clients in need of reliable and cost-effective solutions for their slip ring requirements.{Company Name} is proud to offer a comprehensive range of services, including refurbishment, repair, and custom design of slip rings for a wide variety of applications. With a focus on quality, precision, and customer satisfaction, {Company Name} is dedicated to meeting the unique needs of each client and delivering solutions that exceed expectations.For companies in need of reliable and high-performance slip ring refurbishment services, {Company Name} is the trusted partner of choice. With a proven track record of success and a commitment to innovation and excellence, {Company Name} is poised to continue leading the way in the field of slip ring technology.In conclusion, the recent successful completion of the Rov slip ring refurbishment project is a testament to {Company Name}’s expertise and dedication to delivering high-quality solutions for its clients. With a focus on precision, reliability, and customer satisfaction, {Company Name} is proud to be a trusted partner for companies in need of advanced slip ring refurbishment services.

Durable and Lightweight Slip Ring for Your Industrial Needs

It is no secret that slip rings are a crucial component in various industries, enabling the transfer of power and data between rotating and stationary parts of machinery. These industries often require slip rings that are not only efficient and high-performing, but also lightweight to minimize the overall weight of the rotating equipment. This is where the latest innovation in slip ring technology comes into play - the new Lighter Weight Slip Ring from a leading manufacturer in this field.This innovative product is set to revolutionize the way slip rings are used in a wide range of applications, from robotics to wind turbines, and from medical equipment to aerospace technology. With its lightweight design, it offers a solution to the industry’s demand for slip rings that can handle high data and power transfer rates while also being easy to install and maintain.The new Lighter Weight Slip Ring boasts a number of features that set it apart from traditional slip rings. Not only is it significantly lighter in weight, but it also offers improved performance and durability. This makes it an ideal choice for applications where weight and space are at a premium, such as in small drones or compact medical devices.In addition to its lightweight design, this new slip ring incorporates the latest technology to ensure reliable and efficient power and data transfer. It is capable of handling high data rates and power levels, making it suitable for use in demanding industrial environments. This makes it an ideal choice for industries where the reliability and performance of slip rings are critical to the success of their operations.What sets this Lighter Weight Slip Ring apart is the company behind it. With a long history of expertise in slip ring technology, they have been at the forefront of innovation in this field for decades. Their commitment to quality and reliability has earned them a reputation as a trusted provider of slip rings to industries around the world.In addition to their expertise in slip ring technology, the company is also known for its dedication to customer service and satisfaction. They work closely with their clients to understand their specific needs and requirements, and to provide tailored solutions that meet those needs. This customer-focused approach has allowed them to build strong, long-lasting relationships with their clients, who rely on them for high-quality slip rings and exceptional support.The introduction of the Lighter Weight Slip Ring is a testament to the company’s ongoing dedication to innovation and excellence. By continually pushing the boundaries of what is possible in slip ring technology, they are helping to drive forward progress in a wide range of industries. Their commitment to research and development has allowed them to stay ahead of the competition and to continue providing cutting-edge solutions to their clients.As industries continue to evolve and demand more from their equipment, the need for lightweight, high-performance slip rings will only continue to grow. With the introduction of the new Lighter Weight Slip Ring, this leading manufacturer is once again demonstrating their ability to meet the changing needs of their clients and to provide solutions that make a real difference.In conclusion, the new Lighter Weight Slip Ring from this leading manufacturer is set to redefine the way slip rings are used in a wide range of industries. Its lightweight design, combined with its high performance and reliability, makes it an ideal choice for applications where space and weight are at a premium. And with the company’s long-standing commitment to excellence and customer satisfaction, clients can trust that they are getting a top-quality product that meets their specific needs. As industries continue to advance, this innovative slip ring will undoubtedly play a crucial role in driving progress and success.

Compact Hybrid Slip Rings with 36mm Housing Diameter – Perfect for Pneumatic and Hydraulic Needs

In today's world of automation and robotics, slip rings have become an indispensible component for their smooth operation. A slip ring is an electrical device that enables the transmission of electrical signals, power, and data from a stationary to a rotating assembly. A hydraulic/pneumatic slip ring is an advanced type of slip ring that incorporates both hydraulic/pneumatic and electric circuits in a single sleek design. Such slip rings have found widespread applications in various fields such as aerospace, defense, medical, and many more.One of the popular options in the market is the rotarX compact hybrid slip rings, with its unique combination of hydraulic/pneumatic and electrical circuits. These slip rings come with up to 4 media feed-throughs (M5), and are capable of handling up to 6-12 rings at 2A and 300 rpm, with a metal housing. The 36mm housing diameter of these hydraulic/pneumatic slip rings makes them extremely compact and versatile.The rotarX compact hybrid slip rings are perfect for applications in robotic arms, where precision, versatility, and compactness are critical factors. These slip rings offer smooth operation even in harsh environmental conditions, thereby enhancing the longevity of the robotic arm. The hydraulic/pneumatic channels allow for the smooth transmission of fluids, which is crucial in applications like gripping, lifting, and other actuator operations. The electrical circuits enable the transmission of control signals, power, and data, without compromising on the performance.With the growing demand for robotic arms in various industries, the need for advanced slip rings that can handle multiple media and electrical circuits has become paramount. Slip rings like the rotarX compact hybrid slip rings, with their unique design that combines hydraulic/pneumatic circuits with electrical circuits, offer a reliable and efficient solution for all such applications.In conclusion, slip rings have become an integral part of the automation and robotics industry. They enable the smooth transmission of electrical signals, power, and data from a stationary to a rotating assembly. The hydraulic/pneumatic slip rings have added a new dimension to the design and functionality of these components, making them more versatile and efficient. The rotarX compact hybrid slip rings, in particular, offer a reliable and efficient solution for applications in robotic arms, and are a must-have for industries looking to enhance the performance and longevity of their robotic arms.