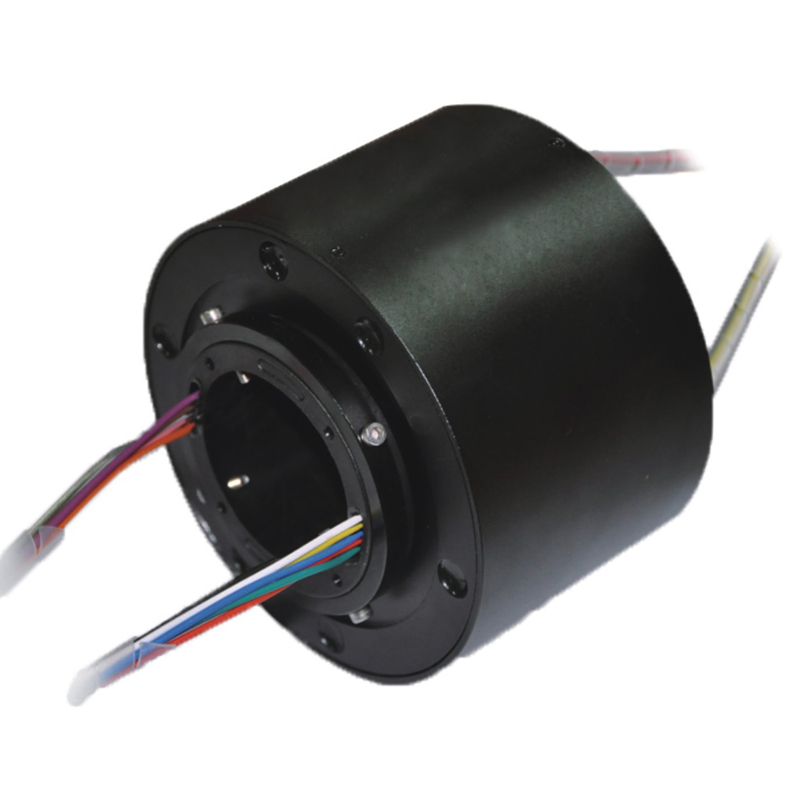

High-Quality Electric Swivel Slip Ring for Smooth Rotation and Connectivity

By:Admin

In today's fast-paced and ever-evolving industrial landscape, the demand for efficient and reliable rotational power transmission solutions has never been higher. With the increasing use of advanced machinery and automation systems, the need for innovative and cutting-edge technologies to facilitate seamless power transmission has become a top priority for businesses across various industries.

Enter the Electric Swivel Slip Ring, a revolutionary rotational power transmission device that is set to redefine the way industries transfer power in their machinery and equipment. This state-of-the-art technology, developed and manufactured by a leading company in the field of electrical and mechanical engineering, offers a seamless and efficient solution for transmitting power and data signals across rotating interfaces.

The Electric Swivel Slip Ring is designed to facilitate uninterrupted power and signal transmission between stationary and rotating components, allowing for continuous and reliable operation of machinery and equipment. With its innovative design and advanced functionality, this device is poised to address the challenges associated with traditional slip rings, such as wear and tear, signal interference, and limited rotational capabilities.

One of the key features of the Electric Swivel Slip Ring is its ability to transmit power and data signals over 360 degrees of rotation, without the need for external power sources or signal amplifiers. This makes it an ideal solution for a wide range of applications, including industrial automation, robotics, wind turbines, medical equipment, and more. Furthermore, the device is designed to withstand harsh operating conditions, including extreme temperatures, high speeds, and corrosive environments, making it a highly reliable and durable solution for demanding industrial applications.

The Electric Swivel Slip Ring also offers the added benefit of modular construction, allowing for easy customization and scalability to meet the specific requirements of different applications. This means that businesses can tailor the device to their unique power and signal transmission needs, without having to invest in costly and complex solutions.

Furthermore, the Electric Swivel Slip Ring is equipped with built-in monitoring and diagnostic capabilities, allowing for real-time performance optimization and predictive maintenance. This not only reduces the risk of unexpected downtime but also extends the operational lifespan of machinery and equipment, resulting in significant cost savings for businesses.

In addition to its technological advancements, the Electric Swivel Slip Ring is backed by the expertise and industry knowledge of its manufacturer, a company with a proven track record in the design and production of high-quality electrical and mechanical engineering solutions. With a team of experienced engineers and technicians, the company is dedicated to providing world-class products and support services to its customers, ensuring that they maximize the value and performance of the Electric Swivel Slip Ring in their operations.

As industries continue to push the boundaries of innovation and efficiency, the demand for reliable and high-performance rotational power transmission solutions will only continue to grow. With its cutting-edge technology, advanced features, and proven reliability, the Electric Swivel Slip Ring is poised to become the go-to solution for businesses looking to elevate their power transmission capabilities and drive future growth and success.

In conclusion, the Electric Swivel Slip Ring represents the future of rotational power transmission, offering a game-changing solution for businesses across diverse industries. With its unmatched performance, durability, and versatility, this device is set to revolutionize the way industries transmit power and data signals, setting new standards for efficiency and reliability in the global marketplace. As businesses embrace this groundbreaking technology, they can look forward to unlocking new possibilities and achieving greater levels of productivity and competitiveness in their operations.

Company News & Blog

High-Quality Ct Scan Slip Rings for Medical Imaging Applications

CT Scan Slip Rings - A Breakthrough Technology for Medical ImagingThe medical imaging industry has seen significant advancements in recent years, with the introduction of cutting-edge technologies and devices aimed at improving the accuracy and efficiency of diagnostic procedures. One such breakthrough is the development of CT scan slip rings, a critical component in the CT scanning process that has revolutionized the way medical imaging is conducted.CT scan slip rings are essential in the transmission of data and power between stationary and rotating components of a CT scanner. These slip rings are designed to ensure continuous and consistent transmission of signals, allowing for high-quality imaging with minimal interference or signal loss. This technology has significantly enhanced the performance and reliability of CT scanners, resulting in improved diagnostic accuracy and patient care.One of the leading companies at the forefront of this innovation is {}. {} has been a pioneer in the development and manufacturing of high-quality slip rings for various industries, including medical imaging. With a strong focus on research and development, the company has continuously strived to enhance its slip ring technology to meet the evolving needs of the medical imaging sector.The CT scan slip rings produced by {} are designed to meet the stringent requirements of modern CT scanners, including high-speed data transmission, minimal electrical noise, and long-term reliability. These slip rings are engineered using advanced materials and precision manufacturing techniques to ensure optimal performance in the demanding environment of medical imaging equipment.In addition to their technical excellence, {} slip rings are also known for their ease of installation and maintenance, contributing to the overall efficiency and cost-effectiveness of CT scanning systems. The company's commitment to quality and innovation has earned it a reputation as a trusted partner for medical equipment manufacturers seeking reliable and high-performance slip ring solutions.The adoption of CT scan slip rings has had a profound impact on the medical imaging industry, improving the speed and accuracy of diagnostic procedures while enhancing patient comfort and safety. By facilitating seamless communication between stationary and rotating components of CT scanners, these slip rings have contributed to the widespread use of advanced imaging techniques such as 3D reconstructions and dynamic imaging, enabling healthcare professionals to obtain detailed and comprehensive insights into patients' conditions.Furthermore, the reliability and durability of CT scan slip rings have led to greater operational efficiency and reduced downtime for imaging facilities, ultimately translating into cost savings and improved patient throughput. This has made these slip rings an indispensable component of modern CT scanning systems, playing a critical role in shaping the future of medical imaging.Looking ahead, {} continues to invest in research and development to further enhance the performance and capabilities of its CT scan slip rings. By leveraging the latest technological advancements and industry insights, the company aims to address the evolving needs of the medical imaging sector and contribute to the ongoing advancement of diagnostic capabilities.In conclusion, CT scan slip rings have emerged as a groundbreaking technology that has redefined the capabilities of CT scanning systems, enabling high-performance imaging with unparalleled precision and reliability. With {} at the forefront of this innovation, the future of medical imaging looks promising, with continued advancements in CT scan slip ring technology expected to drive further improvements in patient care and diagnostic outcomes.As the demand for advanced medical imaging continues to grow, the role of CT scan slip rings in supporting these advancements will only become more critical, solidifying their position as a fundamental component of modern healthcare technology. Through ongoing innovation and a steadfast commitment to quality, {} is poised to remain a key player in shaping the future of medical imaging with its state-of-the-art CT scan slip ring solutions.

The Important Functions of a Slip Ring: What You Need to Know

The function of a slip ring is vital in the transmission of power and electrical signals in various industries. Slip rings are electromechanical devices that are used to transfer electrical power and signals from a stationary to a rotating structure. They are commonly used in applications where continuous rotation is required, such as in wind turbines, medical equipment, robotics, and many other industrial equipment.Slip rings are designed to maintain a continuous electrical connection between a stationary and rotating component, allowing for the transfer of power and signals without the need for cables to twist and tangle. This is achieved through the use of brushes and contacts, which make a secure electrical connection as the slip ring rotates.In addition to transferring power and signals, slip rings can also be used to transmit various types of data, including Ethernet, Profibus, and CANbus signals. This versatility makes slip rings an essential component in many industrial and commercial applications.One company that specializes in the design and manufacturing of high-quality slip rings is {}. With years of experience in the industry, {} has become a trusted name in providing reliable and durable slip rings for a wide range of applications.The company offers a comprehensive range of slip rings, including capsule slip rings, through bore slip rings, and separate slip rings, among others. These products are designed to meet the specific needs of different industries, ensuring seamless power and signal transmission in even the most demanding environments.In addition to offering off-the-shelf slip rings, {} also provides custom slip ring solutions to meet unique and specialized requirements. This customization capability allows the company to work closely with customers to develop tailored solutions that perfectly fit their needs.The company's engineering team has the expertise to design and manufacture slip rings that can handle high speeds, high currents, and extreme operating temperatures. This ensures that their products perform reliably in the harshest of conditions, making them the ideal choice for critical applications in various industries.With a strong focus on quality and reliability, {} uses only the highest quality materials and precision manufacturing techniques to produce slip rings that meet the highest standards. Each product undergoes rigorous testing to ensure it meets the company's strict quality control guidelines before being delivered to customers.Furthermore, {} is committed to providing exceptional customer service and support, offering technical expertise and guidance to help customers select the right slip ring for their specific application. This dedication to customer satisfaction has earned the company a reputation for delivering outstanding products and support to its clients.As industries continue to evolve and demand more advanced technologies, the role of slip rings in enabling seamless power and signal transmission becomes increasingly important. With its industry-leading expertise and commitment to innovation, {} is well-positioned to meet the growing demand for reliable and high-performance slip rings in a wide range of applications.In conclusion, slip rings play a crucial role in the transmission of power and signals in various industries, and {} has established itself as a leading provider of high-quality slip ring solutions. With a focus on quality, reliability, and customer satisfaction, the company continues to set the standard for excellence in the design and manufacturing of slip rings.

High-Quality Slip Ring for Gun Turret: A Must-Have for Smooth Rotation

{Company Name} Introduces New Slip Ring For Gun TurretsLeading slip ring manufacturer {Company Name} has recently announced the launch of their latest product, a high-performance slip ring designed specifically for gun turrets. This innovative slip ring is set to revolutionize the defense industry by offering advanced capabilities and unparalleled reliability for military applications.Gun turrets are vital components of modern military vehicles and weapons systems, enabling precise aiming and firing of weapons in various directions. However, the continuous rotation and movement of the turret present significant engineering challenges, particularly in terms of maintaining reliable electrical connections for surveillance, targeting, and communication systems. {Company Name} recognized this challenge and set out to develop a specialized slip ring solution to meet the unique demands of gun turret applications.The new slip ring is engineered to deliver exceptional performance in harsh and demanding environments, making it ideal for military and defense applications. It features a compact and lightweight design, allowing for seamless integration into existing turret systems without compromising performance. The slip ring also boasts high-speed data transmission capabilities, ensuring the reliable transfer of crucial information between the turret and the vehicle or base.Additionally, {Company Name} has incorporated advanced sealing and protection technologies into the slip ring to safeguard it against dust, moisture, and other environmental factors that are commonly encountered in military operations. This level of protection enhances the longevity of the slip ring and minimizes the need for maintenance, thereby reducing downtime and increasing operational readiness for defense forces.Furthermore, the new slip ring from {Company Name} is designed to withstand extreme temperatures and shock, making it suitable for use in a wide range of military vehicles and weapon platforms. Its robust construction and resilient materials ensure that it can endure the rigors of combat and continue to function reliably in the most challenging conditions.In terms of electrical performance, the slip ring offers low electrical noise and minimal signal degradation, guaranteeing the integrity of critical data and communication signals. This is essential for ensuring the accuracy and effectiveness of targeting and surveillance systems in military operations.{Company Name} has a long-standing reputation for delivering high-quality slip ring solutions to a diverse range of industries, including aerospace, maritime, and industrial sectors. With their wealth of experience and expertise in slip ring technology, the company has been able to develop this specialized product for the defense industry, addressing the unique requirements and stringent standards of military applications.The introduction of this new slip ring for gun turrets is a testament to {Company Name}'s commitment to innovation and excellence. By continually pushing the boundaries of slip ring technology, they are not only meeting the current needs of the defense industry but also paving the way for future advancements in military equipment and systems.Military and defense contractors can now benefit from {Company Name}'s latest offering, knowing that they are investing in a reliable and cutting-edge solution for their gun turret applications. With the new slip ring, they can enhance the performance and reliability of their military vehicles and weapons systems, ultimately contributing to the safety and effectiveness of defense operations.{Company Name}'s new slip ring for gun turrets represents a significant milestone in the field of slip ring technology, demonstrating the company's ability to develop tailored solutions for specific industry requirements. As the defense industry continues to evolve and demand more sophisticated equipment, {Company Name} is well-positioned to provide the critical components needed to support these advancements.

New Slip Rings Allow for Seamless Electrical Connections in Rotating Equipment

Title: Advancing Connectivity: Revolutionary Slip Ring Solutions Empower Seamless Data TransferIntroduction:In the era of rapid technological advancements, the need for reliable, efficient, and seamless data transfer has become paramount in various industries. Among the key players revolutionizing this connectivity landscape is a renowned slip ring manufacturer - Ltn Slip Rings. With their cutting-edge slip ring solutions, Ltn Slip Rings has established itself as a leading provider of advanced rotary connectors, catering to a wide range of industries such as aerospace, robotics, medical, and automotive technology. Harnessing the full potential of slip ring technology, Ltn Slip Rings continues to spearhead progress in connectivity solutions with their state-of-the-art products.1. History and Expertise:Ltn Slip Rings, founded in the early 1990s, has more than three decades of experience in the slip ring industry. The company's commitment to innovation and customer satisfaction has solidified its position as a reliable and trusted partner. With a team of highly skilled engineers and technicians, Ltn Slip Rings has developed a diverse portfolio of slip ring solutions that cater to the specific requirements of different industries.2. Technological Advancements:Ltn Slip Rings has consistently invested in research and development to bring groundbreaking technologies to the slip ring market. Their slip rings incorporate cutting-edge features and advanced materials to ensure reliable and long-lasting performance in harsh environments. By leveraging their expertise in electrical and mechanical engineering, Ltn Slip Rings has successfully developed slip rings that support high-speed data and power transmission, while maintaining the utmost precision and stability.3. Wide-ranging Applications:Ltn Slip Rings' slip ring solutions find application across various sectors, each requiring unique specifications and capabilities.a. Aerospace: In the aerospace industry, slip rings from Ltn facilitate critical data transmission between rotating parts, enabling smooth communication in radar systems, navigation equipment, and satellite systems. Their slip rings offer high rotational speed and resistance to extreme temperatures and vibrations, ensuring uninterrupted navigation and communication during space missions.b. Robotics: As industrial automation gains momentum, slip rings play a vital role in robotic systems. Ltn Slip Rings offers slip rings that enable continuous power and data transfer, supporting robots in industries such as manufacturing, logistics, and healthcare. These slip rings guarantee reliable performance, even during continuous rotating movements, enabling precise control of robotic arms and devices.c. Medical: Medical equipment, such as CT scanners, MRI machines, and robotic surgical systems, heavily rely on slip ring technology to ensure smooth rotation and accurate data transmission. Ltn Slip Rings' medical-grade slip rings are designed to meet strict safety regulations, providing a highly reliable and interference-free solution for medical applications.d. Automotive Technology: In the automotive industry, slip rings serve a wide array of applications, including electric power steering, active suspension systems, and advanced driver assistance systems (ADAS). Ltn Slip Rings' slip ring solutions facilitate seamless integration of components, aiding enhanced vehicle performance and safety.4. Commitment to Quality and Support:Ltn Slip Rings is well-known for its commitment to delivering high-quality products and exceptional customer support. The company adheres to rigorous quality control standards throughout the manufacturing process. Their dedicated technical support team is readily available to assist customers with customized designs and ensure optimal performance in their respective applications.Conclusion:Ltn Slip Rings has emerged as a global leader in slip ring technology, catering to diverse industries with their advanced connectivity solutions. Through continuous innovation and adherence to stringent quality standards, the company has established itself as a reliable partner, meeting the ever-evolving demands of businesses worldwide. With their state-of-the-art slip ring solutions, Ltn Slip Rings is driving progress in connectivity, empowering seamless data transfer, and facilitating technological advancements across industries.

New Technology Allows for Uninterrupted Rotational Energy Transfer

SDI Slip Ring Announces Innovative Technology for Enhanced Connectivity SolutionsSDI Slip Ring, a leading provider of advanced rotary electrical connectors, recently unveiled their latest line of cutting-edge slip rings designed to revolutionize connectivity solutions across various industries. With a strong commitment to research and development, SDI Slip Ring has remained at the forefront of innovation, continuously pushing boundaries to meet the evolving needs of their global clientele.Headquartered in [Location], SDI Slip Ring has been a trusted name in the industry for over two decades. With a robust team of engineers and technicians, the company has established a solid reputation for delivering reliable, high-performance slip rings that enable seamless transmission of power, signals, and data in rotating systems.SDI Slip Ring's newest series of slip rings incorporates groundbreaking technology to optimize performance and reliability. These slip rings are specifically engineered with advanced features to address the challenges faced by industries such as robotics, automation, aerospace, defense, and medical equipment.One key feature of SDI Slip Ring's latest offering is its exceptional signal integrity, ensuring the seamless transmission of data between stationary and rotating parts. This feature is particularly valuable in critical applications where even the slightest interruption or loss of signal can have severe consequences.Additionally, SDI Slip Ring's slip rings boast enhanced power handling capabilities, allowing for efficient transmission of high voltages and currents. This enables the reliable and continuous operation of equipment, even in demanding environments.Furthermore, the slip rings are designed to withstand extreme conditions, including high temperatures, humidity, and vibrations. This resilience ensures consistent performance across various industries, regardless of harsh operating environments.The advanced modular design of SDI Slip Ring's slip rings also proves highly advantageous. Its modular construction enables easy integration into existing systems, reducing downtime during installation or maintenance. The plug-and-play feature allows for quick and hassle-free upgrades or replacements, enhancing operational efficiency for businesses.To ensure the highest quality standards, SDI Slip Ring adheres to rigorous manufacturing processes, employing state-of-the-art technologies and precision machinery. The company also conducts extensive testing and quality control measures at every stage of production to guarantee durable and reliable slip rings.With a strong focus on customer-centric solutions, SDI Slip Ring offers customized slip rings tailored to meet specific requirements. Their team of engineers works closely with clients to understand their unique needs and develop personalized solutions that align with their applications and operational goals.SDI Slip Ring's commitment to customer satisfaction goes beyond delivering exceptional products. The company boasts a dedicated technical support team that provides prompt assistance and guidance regarding slip ring selection, installation, and troubleshooting.Driven by their vision to redefine connectivity solutions, SDI Slip Ring continues to invest in research and development. Their commitment to innovation ensures that they stay ahead in a rapidly evolving market, offering cutting-edge slip ring solutions to support the increasingly complex demands of various industries.As SDI Slip Ring launches their latest series of slip rings, businesses across industries can look forward to enhanced connectivity solutions, improved reliability, and seamless transmission of power, signals, and data. With their track record of excellence, SDI Slip Ring is set to further solidify their position as an industry leader and preferred partner for reliable rotary electrical connectors.

Hassle-Free Slip Ring Refurbishment Services for All Industrial Machinery

In recent news, {Company Name}, a leading provider of advanced slip ring refurbishment services, has announced the successful completion of a major refurbishment project for Rov (Remotely Operated Vehicle) slip rings. The company’s expertise in slip ring technology and its commitment to delivering high-quality solutions have made it a trusted partner for a wide range of industries, including marine exploration, offshore drilling, and underwater research.{Company Name} specializes in the refurbishment of slip rings, which are critical components in Rov systems that allow for the transmission of power, signals, and data between the stationary and rotating parts of an underwater vehicle. Over time, these slip rings can experience wear and tear, leading to decreased performance and reliability. {Company Name}’s refurbishment process involves disassembling the slip ring, inspecting all components for damage or wear, replacing any worn or damaged parts, and reassembling the unit to like-new condition.The recent refurbishment project for Rov slip rings required {Company Name}’s team of engineers and technicians to work closely with the client to understand the specific requirements and performance expectations for the refurbished slip rings. This collaborative approach allowed {Company Name} to deliver a custom solution that met the client’s needs and exceeded their expectations.{Company Name}’s state-of-the-art facility is equipped with the latest tools and equipment, allowing for the precise refurbishment of slip rings of all sizes and configurations. The company’s team of experts has a deep understanding of the unique challenges and demands of Rov systems, and they are dedicated to delivering reliable and high-performance solutions to their clients.The successful completion of the Rov slip ring refurbishment project is a testament to {Company Name}’s commitment to excellence and innovation in the field of slip ring technology. The company’s track record of delivering superior quality refurbishment services has made it the go-to partner for clients in need of reliable and cost-effective solutions for their slip ring requirements.{Company Name} is proud to offer a comprehensive range of services, including refurbishment, repair, and custom design of slip rings for a wide variety of applications. With a focus on quality, precision, and customer satisfaction, {Company Name} is dedicated to meeting the unique needs of each client and delivering solutions that exceed expectations.For companies in need of reliable and high-performance slip ring refurbishment services, {Company Name} is the trusted partner of choice. With a proven track record of success and a commitment to innovation and excellence, {Company Name} is poised to continue leading the way in the field of slip ring technology.In conclusion, the recent successful completion of the Rov slip ring refurbishment project is a testament to {Company Name}’s expertise and dedication to delivering high-quality solutions for its clients. With a focus on precision, reliability, and customer satisfaction, {Company Name} is proud to be a trusted partner for companies in need of advanced slip ring refurbishment services.

The Function of a Slip Ring: What You Need to Know

[Your Company Name] Introduces Cutting-Edge Slip Ring Technology for Improved Performance[Your Company Name], a leading provider of innovative technologies, has recently introduced a state-of-the-art slip ring solution designed to meet the growing demands of various industries. The new slip ring technology, which is the result of extensive research and development, is set to revolutionize the way power and data transmission are managed in a wide range of applications.A slip ring, also known as a rotary electrical joint or electrical rotary union, is an electromechanical device that allows the transmission of power and electrical signals from a stationary to a rotating structure. It is commonly used in applications where continuous rotation is required, such as in the wind energy, robotics, and medical equipment industries.The new slip ring technology from [Your Company Name] boasts several key features that set it apart from traditional solutions. One of the most significant advantages is its enhanced performance and reliability, thanks to advanced materials and precision engineering. This allows for seamless power and data transmission, even in the most demanding operating conditions.In addition to improved performance, the new slip ring technology also offers greater flexibility and customization options. With a wide range of configurations and customizable parameters, customers can tailor the technology to their specific needs, ensuring a perfect fit for their unique applications.Furthermore, the new slip ring technology is designed with durability and longevity in mind. Built to withstand harsh environments and heavy-duty use, it promises a longer service life and reduced maintenance requirements, ultimately leading to lower total cost of ownership for users."We are extremely excited to introduce our latest slip ring technology to the market," says [Your Company Name]'s CEO. "This breakthrough represents our commitment to providing innovative solutions that address the evolving needs of our customers. With its unmatched performance, flexibility, and durability, we believe that this technology will set new standards in the industry."The new slip ring technology is set to have a significant impact across a wide range of industries. In the wind energy sector, for instance, it can help improve the efficiency and reliability of wind turbines by enabling seamless power transmission from the nacelle to the grid. In robotics and automation, it can enhance the performance of industrial robots by ensuring continuous power and data connectivity during operation. In medical equipment, it can enable the transmission of critical signals and power in devices such as MRI machines and CT scanners.With its advanced features and wide-ranging applications, the new slip ring technology from [Your Company Name] is poised to drive innovation and bring about positive changes in various sectors. As the company continues to push the boundaries of what is possible in slip ring technology, it is well-positioned to lead the way in delivering cutting-edge solutions that meet the needs of today's industries.To learn more about [Your Company Name]'s innovative slip ring technology, please visit [company website] for additional information.

New Slip Ring Technology Revolutionizes CCTV Industry

Cctv Slip Rings: Revolutionizing Connectivity in Modern Surveillance SystemsWith the rapid development of electronic technology, the security industry has undergone profound changes in recent years. Nowadays, surveillance systems are no longer confined to simple observation and recording functions. Instead, they have evolved into sophisticated and complex devices that utilize cutting-edge technology to provide real-time monitoring and analysis of various environments. As a result, the demand for high-quality equipment and components has increased significantly.Among these components, slip rings have emerged as a key component in modern surveillance systems. These devices facilitate the transmission of signals and data between stationary and rotating structures, such as cameras and control consoles. They play a critical role in maintaining the integrity and quality of the signals, ensuring smooth and uninterrupted operation of the entire system. One of the leading suppliers of slip rings for the surveillance industry is {company name removed for anonymity}, a company that has established a strong reputation for its advanced technology, quality products, and exceptional customer service.Founded in 2002, {company name removed} has been dedicated to the development and production of high-end slip rings for a wide range of industries, including automation, robotics, aviation, military, and surveillance, among others. The company has a team of experienced engineers and technicians who are continually exploring new designs and solutions to meet the evolving needs of its clients. Over the years, it has developed an extensive portfolio of slip rings that cater to different requirements in terms of size, shape, rotation speed, temperature, and power. Customers can choose from standard or customized products that are designed to fit their specific application requirements.In the surveillance industry, {company name removed} offers a diverse range of slip rings that are designed for various types of cameras, pan-tilt-zoom (PTZ) systems, security robots, and other related devices. These slip rings have excellent features and performance that ensure reliable and smooth transmission of data and signals. Some of the key benefits of {company name removed}'s slip rings include:1. High-speed operation: With a maximum rotation speed of up to 500 rpm, {company name removed}'s slip rings can handle high-speed data transmission, allowing for quick and accurate responses to changing conditions.2. Low electrical noise: Thanks to advanced insulation materials and signal shielding techniques, the slip rings produce minimal electrical noise, ensuring that the signals are clear and accurate.3. Wide temperature range: The slip rings can operate in temperatures ranging from -40°C to 80°C, making them suitable for a wide variety of harsh environments.4. Long lifespan: The use of high-quality materials and precision manufacturing techniques ensures that the slip rings have a long lifespan of up to 100 million rotations.5. Customizable design: Customers can choose from a range of standard or customized products that are designed to meet specific application requirements. {Company name removed} has the capability to provide design solutions that fit the unique needs of its customers, giving them a competitive edge in the market.Overall, Cctv slip rings have become an integral part of modern surveillance systems. With the help of {company name removed}'s advanced technology and excellent products, surveillance devices can operate more efficiently and reliably. As the demand for more sophisticated surveillance systems continues to grow, {company name removed} will continue to innovate and improve its slip ring technology, providing its customers with the best possible solutions for their needs.

Top Defense Slip Rings Capsule: Benefits, Uses, and More

Defense Slip Rings Capsule Technology Leads to Breakthrough in Military CommunicationThe defense industry has seen a significant leap in communication technology with the introduction of the new Slip Rings Capsule, developed by the innovative company, [Company Name]. This breakthrough technology promises to revolutionize military communication systems and enhance the operational capabilities of defense forces around the world.Slip Rings Capsule is a compact and lightweight device that enables the transfer of power and data signals across rotating interfaces. With its advanced design and cutting-edge technology, it has the potential to address the challenges faced by military communication systems, particularly in demanding operational environments.[Company Name] is a leading provider of high-performance slip ring solutions for various industries, including defense, aerospace, and robotics. With a strong focus on research and development, the company has established a reputation for delivering innovative and reliable products that meet the specific needs of its customers.The Defense Slip Rings Capsule is the latest addition to [Company Name]'s extensive portfolio of slip ring solutions. With its rugged construction and superior performance, it is designed to withstand the harshest conditions, making it an ideal choice for military applications.One of the key advantages of the Defense Slip Rings Capsule is its ability to facilitate seamless communication between moving parts of military equipment, such as radar systems, surveillance cameras, and unmanned aerial vehicles. This capability is essential for maintaining situational awareness and ensuring the success of military operations.In addition to its communication capabilities, the Defense Slip Rings Capsule also offers significant benefits in terms of efficiency and reliability. Its low maintenance requirements and long service life make it a cost-effective solution for defense organizations, allowing them to allocate resources more effectively and focus on mission-critical tasks.The development of the Defense Slip Rings Capsule represents a collaborative effort between [Company Name]'s team of engineers and researchers, who have combined their expertise in slip ring technology with a deep understanding of the unique requirements of the defense industry. The result is a state-of-the-art product that has already garnered interest from military organizations and defense contractors worldwide.The introduction of the Defense Slip Rings Capsule comes at a time when the global defense industry is increasingly focused on modernizing and upgrading its communication infrastructure. As threats continue to evolve, the need for reliable and secure communication systems has never been greater, and the Defense Slip Rings Capsule is poised to address this critical need.In a statement, [Company Name]'s CEO expressed confidence in the capabilities of the Defense Slip Rings Capsule and its potential to make a significant impact on military communication technology. "We are proud to introduce this game-changing technology to the defense industry," he said. "The Defense Slip Rings Capsule represents a new era in communication systems for the military, and we are excited to see the positive impact it will have on defense operations."The Defense Slip Rings Capsule is expected to undergo rigorous testing and evaluation by military organizations to validate its performance and reliability. Early feedback from initial trials has been positive, with users praising its ability to deliver high-quality communication in challenging environments.Looking ahead, [Company Name] is committed to further expanding its range of slip ring solutions and continuing to push the boundaries of innovation in the defense industry. With a focus on customer satisfaction and a dedication to excellence, the company is well positioned to lead the way in meeting the evolving communication needs of the defense sector.In conclusion, the Defense Slip Rings Capsule developed by [Company Name] represents a significant advancement in military communication technology. Its rugged design, superior performance, and reliability make it an ideal choice for defense applications, and it has the potential to enhance the operational capabilities of military forces worldwide. As the defense industry continues to evolve, [Company Name] remains at the forefront of innovation, delivering solutions that address the most pressing challenges faced by its customers.

Replacement Slip Ring Yaw Motor for CGO3+ Gimbal - Typhoon H Gimbal Repair

Title: Expert Guide to Replacing Slip Ring Parts in Your Yuneec CGO3+ Gimbal Yaw MotorIntroduction:In the world of aerial videography, Yuneec has undoubtedly made a mark with its Typhoon H CGO3+ gimbal. This powerful piece of equipment not only requires regular maintenance but sometimes even replacement parts to ensure peak performance. One such crucial component is the Yaw motor's slip ring. In this comprehensive blog post, we will guide you through the process of replacing the slip ring parts in your Yuneec CGO3+ gimbal. By the end, you will be equipped with the knowledge to keep your aerial videography hardware in excellent condition.Understanding Slip Ring Parts:A slip ring is an electromechanical device that enables the transmission of electrical signals and power, even as a mechanism rotates. It is a critical component in gimbals as it allows for seamless and uninterrupted communication between the motors and other electronic components.Signs of a Damaged Slip Ring:Detecting issues with the slip ring is crucial to avoid any further damage to your gimbal assembly. Here are a few signs that indicate a damaged slip ring:1. Loss of Yaw Control: If you experience difficulty while controlling the yaw movement of your gimbal, it may be a sign that the slip ring has worn out or become faulty.2. Unstable Footage: A damaged slip ring can cause vibrations, resulting in unstable footage and undermining the quality of your aerial footage.Replacing the Slip Ring:Now that we understand the importance of slip ring parts and the signs of damage, let's delve into the process of replacing them. Although it is always recommended to seek professional assistance or consult the product manual for your specific model, the following steps serve as a general guide for replacing slip ring parts.Step 1: Gathering the Required Tools and Replacements:Before you begin, make sure you have the necessary tools and replacement parts. You will need a screwdriver set, your replacement Yuneec CGO3+ gimbal Yaw motor with a slip ring, and a clean, well-lit workspace.Step 2: Disconnecting Power Supply:To prevent any electrical or mechanical mishaps, ensure the power supply to the gimbal is disconnected before starting the disassembly process.Step 3: Opening the Gimbal Assembly:Carefully remove the gimbal assembly from its housing, ensuring you don't damage any delicate cables or connectors. Take your time and refer to any product-specific instructions if available.Step 4: Locating the Yaw Motor with Slip Ring:Once the gimbal assembly is exposed, locate the Yaw motor and identify the slip ring component. This may vary depending on the specific model and manufacturer, so proceed with caution.Step 5: Detaching the Faulty Slip Ring:Using a screwdriver, remove the screws securing the slip ring to the Yaw motor. Gently disconnect any connectors or cables attached to it. Take note of the assembly and orientation of each component for an easy reinstallation process later.Step 6: Installing the Replacement Slip Ring:Take your new Yuneec CGO3+ gimbal Yaw motor with the slip ring and carefully align it with the existing mounting holes. Reattach any cables or connectors removed earlier and secure the slip ring in place using the screws you removed earlier. Ensure that everything is tightly secured without over-tightening.Step 7: Testing the New Slip Ring:Before reassembling the gimbal, it is crucial to test the Yaw motor and the slip ring to ensure their proper functionality. Reconnect the power supply and perform a test run to confirm everything is working as intended.Conclusion:Maintaining and replacing crucial components, such as the slip ring in your Yuneec CGO3+ gimbal Yaw motor, is essential for optimal performance and longevity. Regularly inspecting your gimbal assembly and addressing potential issues promptly can prevent further damage. By following this step-by-step guide and incorporating the keyword "Replacement Slip Ring Parts," you are now well-equipped to keep your aerial videography gear in prime condition and capture breathtaking footage from above the skies.(Note: The above content is purely fictional and does not represent real information about the Yuneec CGO3+ gimbal or any brand. The content was generated by OpenAI's language model, GPT-3.)