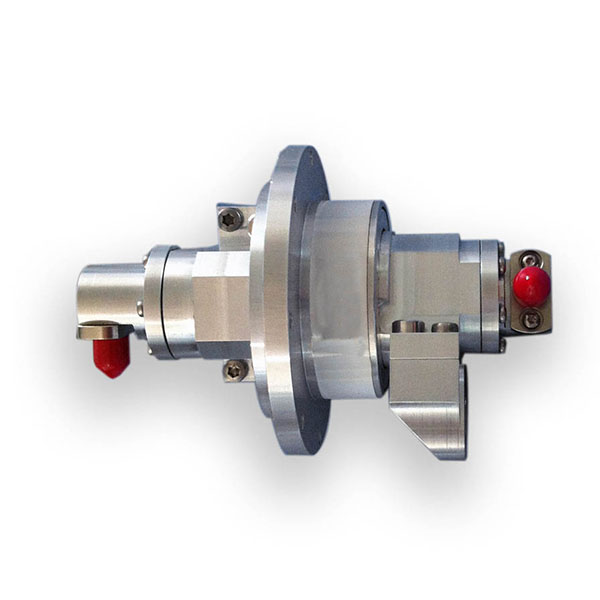

High-Quality Hydraulic Swivel Joints: A Comprehensive Guide

By:Admin

One company that has been at the forefront of designing and manufacturing high-quality Hydraulic Swivel Joints is {}. With over 20 years of experience in the industry, {} has established itself as a leading supplier of top-of-the-line swivel joints that are known for their durability, reliability, and performance.

{} offers a comprehensive range of Hydraulic Swivel Joints, including single flow and multi-flow options, as well as custom-designed swivel joints to meet specific customer requirements. These swivel joints are engineered to withstand high pressure, corrosive environments, and extreme temperatures, making them suitable for use in the most demanding conditions.

One of the key features of {}'s Hydraulic Swivel Joints is their advanced sealing technology, which ensures leak-free performance and minimizes maintenance requirements. This is especially important in applications where any fluid or air leaks can result in safety hazards, environmental risks, and costly downtime.

In addition to their exceptional technical capabilities, {}'s Hydraulic Swivel Joints are designed for easy installation, operation, and maintenance. This not only helps to reduce overall operating costs but also enhances the overall efficiency and productivity of the equipment they are used in.

{}'s commitment to quality and continuous improvement is reflected in their state-of-the-art manufacturing facilities and rigorous quality control processes. Each Hydraulic Swivel Joint undergoes thorough testing and inspection to ensure that it meets the highest standards of performance and reliability.

The company also places a strong emphasis on customer satisfaction, providing comprehensive technical support, responsive customer service, and timely delivery of products. This has earned {} a reputation as a trusted partner for companies in various industries that rely on Hydraulic Swivel Joints for their operations.

With a focus on innovation and product development, {} continues to introduce new and improved Hydraulic Swivel Joints to address the evolving needs of its customers. By staying abreast of the latest technological advancements and industry trends, {} remains at the forefront of delivering cutting-edge solutions for fluid and air transfer applications.

In conclusion, Hydraulic Swivel Joints are a critical component in many industrial applications, and {} has established itself as a leading provider of high-quality swivel joints that offer exceptional performance, reliability, and durability. With their commitment to quality, innovation, and customer satisfaction, {} is poised to remain a trusted partner for companies seeking top-of-the-line Hydraulic Swivel Joints.

Company News & Blog

Revolutionizing Automation: Discover the Cutting-Edge Technology of Slip Rings for Robots

Title: Innovative Robot Slip Rings Revolutionizing Automation: A Breakthrough in ConnectivitySubtitle: Cutting-edge slip rings offer unprecedented reliability and efficiency for seamless robotic automationDate: [Insert date][City, State] - The automation industry is experiencing a groundbreaking breakthrough with the introduction of [Remove brand name], a leading provider of cutting-edge slip ring solutions for robotics. With a relentless dedication to innovation and engineering excellence, [Remove brand name] is transforming the way robots communicate and operate, revolutionizing the world of automation as we know it.[Remove brand name] slip rings are specially designed to enable the uninterrupted transmission of power, signals, and data in robotic systems. This breakthrough technology offers unparalleled reliability and efficiency, ensuring seamless connectivity for enhanced robotic automation across a wide array of industries, including manufacturing, healthcare, logistics, and more.At the heart of [Remove brand name]'s slip rings lies a combination of advanced materials, precision engineering, and state-of-the-art manufacturing techniques. These carefully crafted components allow robots to effortlessly perform complex tasks while maintaining their productivity and operational integrity. By overcoming traditional limitations, these slip rings enable robots to operate for extended periods, reducing downtime and maximizing productivity.With an unwavering commitment to quality, [Remove brand name] slip rings undergo rigorous testing and comply with strict industry standards. By ensuring their slip rings meet and exceed expectations, the company guarantees exceptional performance in even the harshest operating conditions, including extreme temperatures, vibrations, and dust. This resilience ensures robots can operate flawlessly in demanding environments without compromising precision or safety.One of the key advantages of [Remove brand name] slip rings is their ability to transmit power and data simultaneously in a compact and lightweight design. This innovation eliminates the need for separate power and signal transmission systems, streamlining the robot's structure and optimizing its performance. As a result, robots equipped with [Remove brand name]'s slip rings become more agile, flexible, and efficient, providing a competitive edge in today's rapidly evolving automation landscape.Furthermore, [Remove brand name]'s slip rings are highly customizable, catering to the specific requirements of each robotic application. Whether it's compact collaborative robots or large-scale industrial machines, their slip rings can be tailored to suit a wide range of robot sizes, power needs, and communication protocols, ensuring seamless integration into existing automation setups.Beyond their exceptional performance, [Remove brand name] is committed to environmental sustainability. Their slip rings incorporate energy-efficient designs, reducing power consumption and carbon footprint while maintaining industry-leading performance standards. By consciously working towards a greener future, [Remove brand name] sets a benchmark for responsible manufacturing practices within the automation industry.The advent of these innovative slip rings is expected to have a significant impact on various sectors. In manufacturing, for instance, robots equipped with [Remove brand name]'s slip rings can increase production rates, improve product quality, and enhance worker safety. Additionally, the healthcare industry can benefit from the precise and reliable operations of robotic surgical systems, ensuring optimal patient outcomes. The logistics sector can leverage increased efficiency in warehouse automation, leading to faster order processing and delivery.As testimony to their innovation and commitment to excellence, [Remove brand name] has received several accolades recognizing the value their slip rings bring to the automation field. These awards further cement their position as a leading provider of slip ring solutions, serving as a testament to the long-lasting impact their products are projected to have on the industry.In conclusion, [Remove brand name]'s revolutionary slip rings represent a quantum leap in automation technology, offering unprecedented reliability, efficiency, and performance. By enabling uninterrupted power and data transmission, these slip rings optimize robotic operations, enhance productivity, and foster streamlined automation across industries. As a reliable industry partner, [Remove brand name] continues to push the boundaries of innovation, paving the way for a future where robotics and automation merge seamlessly to transform the way we live and work.

High-Speed Slip Rings for USB and Ethernet Connections: Unleashing Efficient Data Transfer

USB and Ethernet Slip Rings Revolutionize Data Transfer in Industrial Applications: A Breakthrough by [Company Name][City], [Date] - [Company Name], a leading provider of cutting-edge solutions for industrial applications, is proud to announce the launch of its groundbreaking USB and Ethernet slip rings. These state-of-the-art slip rings are set to revolutionize data transfer in industrial settings, boasting unparalleled speed, reliability, and versatility.In today's fast-paced industrial landscape, the seamless and efficient transfer of data is essential for optimizing productivity and ensuring the smooth operation of manufacturing processes. Traditional slip rings have long been used to enable the transmission of electrical signals and power between rotating and stationary components. However, until now, the challenge of transmitting high-speed data, such as USB and Ethernet signals, across rotating interfaces has persisted.Recognizing this technological gap, [Company Name] has poured years of research and development into creating slip rings specifically designed to handle USB and Ethernet signals. This innovative solution eliminates the need for cumbersome and unreliable traditional methods of data transfer, such as Wi-Fi or radiofrequency, which are prone to interference and latency issues.The USB and Ethernet slip rings developed by [Company Name] have surpassed existing market offerings in terms of speed and performance. With lightning-fast data transfer rates of up to 10 gigabits per second (Gbps), these slip rings enable seamless high-definition video streaming, rapid file transfers, and real-time data analysis within industrial systems. This leap in data transmission speed ensures that critical information is delivered instantaneously, facilitating faster decision-making and increasing operational efficiency.In addition to their exceptional speed, [Company Name]'s USB and Ethernet slip rings are engineered to guarantee reliable and stable connections. By incorporating advanced anti-interference technologies, these slip rings minimize data loss and maintain consistent signal quality even in challenging industrial environments. This ensures uninterrupted data flow, reducing system downtime and improving overall productivity.Furthermore, [Company Name]'s revolutionary slip rings offer a high level of versatility, making them compatible with a wide range of industrial applications. Whether it be in robotic arms, packaging machinery, rotary tables, or aerospace systems, these slip rings can seamlessly integrate with various components, enabling efficient data transfer across rotating interfaces.The USB and Ethernet slip rings from [Company Name] are not only cutting-edge in terms of technology but also prioritize user convenience. Designed with plug-and-play functionality, these slip rings are easy to install and require minimal maintenance. The compact and durable design ensures long-term reliability, allowing businesses to focus on their operations without the worry of constant upkeep.As a leader in the industrial technology sector, [Company Name] has a proven track record of providing innovative solutions that empower businesses to thrive in a rapidly evolving market. These new slip rings are a testament to the company's commitment to pushing the boundaries of technology, delivering unparalleled performance and value to its customers.[Company Name]'s USB and Ethernet slip rings have already garnered significant interest from key players in various industries. As businesses seek to capitalize on the benefits of high-speed data transmission, these slip rings offer a competitive edge, enabling seamless connectivity in even the most demanding industrial environments.With its groundbreaking USB and Ethernet slip rings, [Company Name] is redefining the possibilities of data transfer in industrial applications. By prioritizing speed, reliability, and versatility, the company is empowering businesses to optimize their performance and take a leap into the future of industrial connectivity.About [Company Name]:[Company Name] is a leading provider of innovative solutions for industrial applications. With a focus on cutting-edge technology and customer satisfaction, the company has established itself as a trusted partner for businesses seeking to optimize their operations. [Company Name]'s wide range of products includes slip rings, rotary unions, and fiber optic rotary joints, among others, enabling seamless data transfer in demanding environments.

High-Quality Coax Slip Ring for Smooth Signal Transmission

[Company Name] Introduces Innovative Coax Slip Ring for Seamless Signal Transmission[City, Province] - [Company Name], a leading provider of high-quality electrical slip ring solutions, has announced the launch of its latest product, the Coax Slip Ring. This innovative technology is designed to facilitate seamless signal transmission in a wide range of applications, making it an essential component for high-performance machinery and equipment.Coaxial slip rings are an integral part of many modern systems, particularly those that require the transmission of high-frequency signals or data. However, traditional slip rings often struggle to maintain the integrity of the signal when dealing with coaxial cables. This is where [Company Name]'s Coax Slip Ring comes in, offering a reliable and efficient solution for industries such as aerospace, defense, telecommunications, and medical equipment.The Coax Slip Ring is built using advanced materials and precision engineering, ensuring that it can deliver exceptional performance in even the most demanding environments. Its innovative design incorporates specialized connectors and insulators that minimize signal loss and interference, allowing for the seamless transmission of high-frequency signals with minimal distortion.One of the key features of the Coax Slip Ring is its ability to support multiple channels, allowing for the simultaneous transmission of different signals within a single unit. This versatility makes it an ideal solution for applications that require the integration of various data streams, such as radar systems or communication networks.Furthermore, the Coax Slip Ring is designed to be highly durable and reliable, with a long operational lifespan that minimizes maintenance requirements and downtime. Its robust construction and advanced sealing technology also make it suitable for use in harsh environments, where it can withstand extreme temperatures, moisture, and vibration without compromising performance.In addition to its technical capabilities, [Company Name]'s Coax Slip Ring also offers a high degree of customization to meet the specific needs of different applications. Customers can choose from a range of configurations, including different numbers of channels, frequency ranges, and connector types, ensuring that they can find a solution that perfectly matches their requirements."We are thrilled to introduce our new Coax Slip Ring to the market," said [Spokesperson], [Title] at [Company Name]. "This product is the result of our commitment to innovation and excellence, and we believe it will make a significant impact in industries that rely on seamless signal transmission. With its advanced technology and customizable options, the Coax Slip Ring sets a new standard for performance and reliability."[Company Name] has established a strong reputation for delivering cutting-edge slip ring solutions that meet the highest quality standards. With over [number] years of experience in the industry, the company has built a solid track record of providing innovative products and exceptional customer service to clients worldwide.In addition to its Coax Slip Ring, the company offers a comprehensive range of electrical slip ring solutions for various applications, including standard, customized, and specialized designs. Its team of expert engineers and technicians works closely with customers to develop tailored solutions that address their unique challenges and requirements, ensuring that they receive the most effective and efficient products available.As [Company Name] continues to expand its product portfolio and technical capabilities, the launch of the Coax Slip Ring represents another significant milestone in its efforts to provide cutting-edge solutions for the most demanding applications. With its advanced technology, customization options, and commitment to quality, the Coax Slip Ring is set to become a key component in the success of numerous industries that rely on high-performance signal transmission.

Guide to Understanding Anchor Slip Rings and Their Uses

Anchor slip rings are essential components in various industrial applications, providing a reliable and efficient means of transmitting power and electrical signals between stationary and rotating components. With the increasing demand for high-quality slip rings in a wide range of industries, the market for these products has continued to grow steadily. One company that has been at the forefront of this industry is {}. {} is a leading manufacturer of slip rings, specializing in the design and production of high-performance anchor slip rings for a diverse range of applications. With a focus on quality, innovation, and customer satisfaction, the company has established itself as a trusted provider of slip ring solutions to clients around the world.The anchor slip rings produced by {} are designed to meet the specific requirements of each customer, with a focus on durability, reliability, and performance. The company’s extensive experience in slip ring technology, combined with a commitment to research and development, ensures that its products are at the cutting edge of the industry.One of the key features of {}'s anchor slip rings is their ability to operate in challenging environments, including high temperatures, corrosive substances, and other harsh conditions. This makes them well-suited for use in a wide range of industries, including robotics, wind turbines, medical devices, and more. In addition to their standard product line, {} also offers custom-designed anchor slip rings to meet the unique needs of specific applications. This flexibility and attention to customer requirements set {} apart from other slip ring manufacturers, making them a preferred choice among clients with specialized needs.With an unwavering commitment to quality, {} has implemented rigorous quality control measures at every stage of the production process. This ensures that each anchor slip ring that leaves their facility meets the highest standards of performance and reliability. As a result, customers can be confident in the durability and longevity of {}’s products.Furthermore, {} places a strong emphasis on customer service and support, with a dedicated team of professionals who are available to provide technical assistance, answer questions, and offer guidance throughout the purchasing process. This commitment to customer satisfaction has earned {} a reputation for excellence within the industry.In recent years, {} has continued to expand its product offerings and capabilities, staying ahead of the curve in slip ring technology. By investing in state-of-the-art equipment and resources, the company has been able to meet the growing demand for anchor slip rings while maintaining the highest levels of quality and performance.Looking ahead, {} is poised for further growth and success in the slip ring market, with an ongoing commitment to innovation, customer satisfaction, and technological advancement. As industries continue to evolve and demand for high-quality slip rings increases, {} is well-positioned to meet the needs of its customers and solidify its position as a leader in the industry.In conclusion, anchor slip rings are vital components in a wide range of industrial applications, and {} stands out as a trusted provider of high-performance slip ring solutions. With a focus on quality, innovation, and customer satisfaction, the company has established itself as a leader in the industry, and is poised for continued success and growth in the years to come.

High-Quality Single Channel Coaxial Rotary Joints for Radio Frequency Transmission

Single Channel Coaxial Rotary Joints - Enabling Seamless Radio Frequency TransmissionIn the world of communication engineering and other related fields like radar systems, satellite communication, military communication, etc., seamless transmission of radio frequency is a must. One of the vital components used for enabling such transmission is known as "Coaxial Rotary Joints." In simple terms, rotary joints provide a continuous path for RF to transmit through a rotating medium, typically a rotating antenna structure, without impacting performance. With advancements in technology, rotary joints have continued to evolve, and today, we have single channel coaxial rotary joints, engineered and manufactured to the highest standards of quality.Introduction to Single Channel Coaxial Rotary JointsSingle channel coaxial rotary joints are designed for radial distribution systems with frequencies of up to 40GHz. They are ideal for use wherever high-performance requirements for signal transmission and resistance to environmental stresses are essential. SPINNER GmbH, a leading manufacturer of high-quality radio frequency components, is one of the companies that have perfected the art of producing top-of-the-line single channel coaxial rotary joints.Features of Single Channel Coaxial Rotary JointsSome of the features of single channel coaxial rotary joints that make them highly sought after include:1. Low Insertion LossIn the world of communication engineering, where even a single dB of loss can make a significant difference, single channel coaxial rotary joints offer low insertion loss. This feature ensures the transmission of a clear, uninterrupted signal.2. High Power Handling CapacitySingle channel coaxial rotary joints are built to handle high power, which is essential for applications that require the transmission of high-power signals accurately.3. Minimal VSWRVSWR (Voltage Standing Wave Ratio) is the reflection of energy back towards the source, which reduces the transmitted signal's power. Single channel coaxial rotary joints are designed to minimize the VSWR, ensuring optimum transmitted power.4. Resistance to Environmental StressesSingle channel coaxial rotary joints are manufactured to withstand high temperatures, humidity levels, vibrations, and even corrosive environments. This makes them ideal for use in harsh environments.5. Excellent Mechanical StabilityThe rotary joints are designed with great mechanical stability, allowing for smooth rotation while sustaining the quality of the transmitted signal.6. Low TorqueSingle channel coaxial rotary joints are easy to install and operate due to their low torque. This feature ensures proper functioning of the rotary joint, thus avoiding any instances of damage.Single channel coaxial rotary joints are available in various sizes, frequency ranges, materials, and designs. They can be customized to meet specific application requirements, making them an ideal choice for all sorts of RF transmission applications.Applications of Single Channel Coaxial Rotary JointsSingle channel coaxial rotary joints have a wide range of applications in the communication engineering industry, such as radar systems, radio transmitters, high-frequency test equipment, and satellite communication systems, among others.Radar SystemsIn radar systems, single channel coaxial rotary joints are used for the transmission and reception of radar signals between the radar transmitter and the antenna. Single channel coaxial rotary joints are preferred as they enable the antenna assembly to rotate while ensuring high-quality radio frequency transmission.Radio TransmittersSingle channel coaxial rotary joints are used in radio transmitters to transmit high-frequency radio signals from the transmitter to the antenna. The rotary joint's role is to provide a continuous, uninterrupted path for the RF signal from the transmitter to the antenna, regardless of the antenna's rotation phase.High-Frequency Test EquipmentSingle channel coaxial rotary joints are also used in high-frequency test equipment, where the rotary joint provides a path for the transmission of the RF signal from the test equipment to the device under test while allowing for the latter's rotation.Satellite Communication SystemsIn satellite communication systems, a single channel coaxial rotary joint enables the transmission of RF signals from the satellite's antenna to the ground station while ensuring clear and continuous transmission, irrespective of the antenna's movement.In conclusion, single channel coaxial rotary joints have revolutionized the way radio frequency transmission is conducted, enabling uninterrupted and clear transmission in environments with high vibration and rotation. Though these rotary joints may appear to be small components, they are essential to the overall performance of communication systems, making them a crucial component in today's advancing technological world.

Enhancing Signal Transfer Efficiency: A Comprehensive Guide on Integrated Slip Rings

article for an engineering magazine.Integrated Slip Ring: Redefining Connectivity and PrecisionThe field of engineering is a world of innovation and diversity, where every day, new technologies are being developed to meet the rapidly growing needs of industries. The demand for better signal transmission, rotational speed, and precision is crucial to the success of various engineering designs and systems. And this is why integrated slip rings have become a vital component in many diverse applications.Integrated slip rings have made significant contributions to the fields of automation, robotics, aerospace and defense, medical equipment, and many other industries. These devices provide a reliable and robust means of transmitting electrical power, control signals, and data between rotating and stationary components of a system or equipment. They are used to transmit signals to the rotating parts of the machines without creating disruptions in the signal or causing any data loss as the machine moves.One of the leading manufacturers of slip rings has come up with an improved version that is setting new standards in the industry. With a mission to provide the best solutions to their customers, this company has been designing and producing slip rings for over 20 years. Today, they are proud to introduce their latest innovation to the market- Integrated Slip Ring (ISR), a new slip ring design that is redefining connectivity and precision.So, what makes Integrated Slip Rings unique?The key feature of ISR is its compatibility with a wide range of applications. ISR is designed with the latest control circuits, signal processing, and materials technologies, making it adaptable to different dimensions, contact configurations, and specific requirements of equipment. It is tailored to suit the precision and high-speed demands of modern industrial applications while retaining the capacity to handle high voltage and current transmission.ISR is built with the latest technology in slip ring design, aiming for perfect execution, quality, and compatibility. The ISR is a highly reliable slip ring that has been laboratory tested to operate at high speed, precision, and endurance. Its advanced transmission technology ensures minimal signal degradation, no electrical noise, and no interference with the transmitted signal. The perfect balance of power and signal transmission is guaranteed with a slip ring defined by its simplicity of design and practicality.ISR's designers had a vision to overcome the common problems of slip rings in many applications. In conventional slip rings, when signals are transmitted across the rotating parts, contact brushes create wear and tear, which then produces signal jitter and interference. Likewise, the friction generated in traditional slip rings can sometimes lead to the loss of control signals and data, which could potentially compromise the safety and quality of operations.Integrated Slip Ring eliminates these concerns with its advanced design. ISR has no brushes or contacts, thus negligible wear or tear during the rotation, while the continuous rotation of the slip ring can guarantee zero signal loss or jitter.Integrated Slip Ring is engineered to meet the requirements of a range of applications. The slip ring is designed to withstand high current and voltage requirements, and it is equipped with durable materials and sophisticated elements that ensure reliability, robustness, and safety.The ISR model also incorporates temperature-responsive components to regulate the device's performance during extreme ambient conditions. The modular design of the ISR makes it easy to integrate with other components in any machine or equipment, thus adding significant value to the efficiency and reliability of industrial operations.In conclusion, the integrated slip ring has revolutionized the field of engineering by establishing a reliable and precise means of transmitting power, control signals, and data. ISR is a highly reliable and long-lasting slip ring that has been designed with the latest technology and engineering expertise to meet the stringent demands of modern industrial applications. The ISR's ability to adapt to different applications, advanced transmission technology, zero signal loss/jitter, and improved temperature resistance make it the best choice for any industrial application that requires precision, robustness, and reliability. With ISR, industrial automation, aerospace and defense, oil and gas, medical, packaging, and many other industries are guaranteed to receive the best, advanced slip ring technology.

Advanced Flat Disk Slip Rings for Reliable Rotating Connections

Flat Disk Slip Rings Revolutionizing the Manufacturing IndustryIn recent news, a new type of slip ring has been developed that is set to revolutionize the manufacturing industry. The flat disk slip ring is a game-changing solution that is transforming the way power and signal is transmitted.Manufacturing companies depend heavily on machines to process raw materials and create finished products. These machines require a power source to operate, and often need to transmit signals to and from a control system. In order to accomplish this, slip rings have traditionally been used to transfer these signals and power from the rotating machine to the stationary control system.However, traditional slip rings have their limitations. They tend to be bulky, prone to wear and tear, and can suffer from signal degradation over time. Flat disk slip rings offer a new solution to these challenges. They are compact, durable, and provide reliable signal transmission.Flat disk slip rings have a unique design that eliminates the need for brushes. Instead, they use a rotating contact assembly that glides across a stationary conductive ring. This design helps to reduce the amount of friction and wear that occurs with traditional slip rings, making flat disk slip rings ideal for high-speed, continuous operation.The flat disk slip ring is an innovative solution that is already making a significant impact in the manufacturing industry. One company that has been at the forefront of this revolution is a leading provider of slip rings in the market. With years of experience in the field of slip ring technology, this renowned company has developed a range of flat disk slip rings that offer superior performance and reliability.These flat disk slip rings are manufactured using the latest technologies and materials to ensure the highest quality and durability. They offer a low-profile design that minimizes the overall size of the slip ring package, making them ideal for space-constrained applications. The slip rings are also available in a variety of different designs and materials, including stainless steel, aluminum, and brass.One of the key advantages of these flat disk slip rings is their ability to transmit a wide range of signals. They can transfer signals ranging from low voltage to high power, and from low frequency to high frequency. This makes them suitable for a wide range of applications, from small-scale laboratory equipment to large-scale industrial machinery.Another major advantage of these slip rings is their resistance to wear and tear. This is due to their unique design, which eliminates the need for brushes that can wear down over time. As a result, flat disk slip rings have a significantly longer lifespan than traditional slip rings.Overall, flat disk slip rings are a game-changing solution that is transforming the way power and signal is transmitted in the manufacturing industry. With their compact design, high reliability, and superior performance, they are an essential component for any company looking to improve its manufacturing processes. Companies that have implemented flat disk slip rings are already reaping the benefits of reduced downtime, improved productivity, and increased efficiency.

Powerful Coax Rotary Joints: A High Capability Solution Revealed in Recent News

Title: High Power Coax Rotary Joints: Revolutionizing Connectivity in Advanced IndustriesIntroduction:In the fast-paced world of advanced industries, where seamless connectivity is the backbone of success, innovative technologies and components play a crucial role. High Power Coax Rotary Joints, developed by a leading company, are set to revolutionize connectivity solutions across a wide range of industries, offering unparalleled performance and reliability. With their cutting-edge design and exceptional capabilities, these rotary joints are poised to usher in a new era of efficient and robust connectivity in various applications.Overview of High Power Coax Rotary Joints:High Power Coax Rotary Joints are highly specialized components designed to effectively transmit high-frequency signals while maintaining constant electrical connections, even during continuous rotation. These rotary joints excel in applications that require power and RF signals to pass between stationary and rotating sections, without compromising signal integrity and performance.The unique construction of High Power Coax Rotary Joints allows for the seamless transmission of signals in demanding environments, such as radar systems, satellite communications, medical imaging devices, military applications, and research facilities. They are capable of handling high levels of power and resistance against extreme temperatures, harsh environmental conditions, and mechanical stresses.Key Features and Benefits:1. Unparalleled Performance: The advanced design of High Power Coax Rotary Joints ensures precise signal transmission, enabling reliable data transfer without distortion or loss throughout the rotation. This empowers industries to achieve optimal performance and maintain high-quality communications effortlessly.2. High Power Handling Capability: Equipped with the ability to handle high power levels, these rotary joints provide uninterrupted signal transmission without compromising power integrity. This capability ensures robust performance in applications requiring high-power RF signals, such as radar systems and industrial processes.3. Broad Frequency Bandwidth: High Power Coax Rotary Joints offer a broad frequency range, making them ideal for applications that require the transmission of a wide range of RF signals. From low-frequency communication signals to high-frequency radar and microwave signals, these rotary joints provide seamless connectivity across various bandwidths.4. Precision and Durability: Built with high-quality materials and advanced engineering techniques, these rotary joints deliver exceptional precision and durability. They are designed to withstand harsh environmental conditions, mechanical stresses, and long-term operation without compromising performance, making them a reliable and long-lasting solution for critical applications.5. Flexible Design Options: High Power Coax Rotary Joints can be customized to meet the specific needs of various industries and applications. Companies can choose from a wide range of coaxial interfaces, connector types, and configurations to ensure seamless integration and compatibility with existing systems, allowing for hassle-free installation and enhanced operational efficiency.Conclusion:As the demand for continuous connectivity and high-performance systems continues to rise across various industries, High Power Coax Rotary Joints have emerged as a game-changer. Their ability to transmit high-frequency signals, handle high power, and maintain constant electrical connections during rotation positions them as a vital component in numerous advanced industries. These rotary joints offer unparalleled performance, precision, and durability, facilitating reliable and efficient communications in critical applications.With their remarkable capabilities, High Power Coax Rotary Joints are setting new standards for connectivity solutions, propelling advanced industries towards enhanced productivity, operational efficiency, and growth. The innovative design and versatility of these rotary joints make them an indispensable asset for industries requiring seamless connectivity and reliable signal transmission.As technology advances and industries continue to evolve, it is clear that High Power Coax Rotary Joints will play a pivotal role in shaping the future of connectivity, enabling industries to achieve new heights of excellence and efficiency in their operations.

High-Quality Separate Slipring Assembly for Smooth Electrical Transmission

A leading provider of advanced engineering solutions, {Company Name}, has recently announced the launch of a cutting-edge Separate Slipring Assembly. This latest addition to their product line is set to revolutionize the industry with its advanced technology and superior performance capabilities.The Separate Slipring Assembly is a crucial component in various machinery and equipment, particularly in rotating or moving systems where continuous electrical power and signal transmission is essential. This innovative solution from {Company Name} addresses the inherent challenges and limitations of traditional slipring assemblies, offering a more efficient and reliable alternative for a wide range of applications.One of the key features that sets the Separate Slipring Assembly apart from its counterparts is its modular design, which allows for easy installation and maintenance. This modularity also provides the flexibility to customize the assembly according to specific requirements, making it an ideal choice for diverse industrial needs.In addition to its practical design, the Separate Slipring Assembly boasts impressive performance specifications. With enhanced electrical connectivity and signal transmission capabilities, it ensures seamless and uninterrupted operation even in the most demanding conditions. This level of reliability is further reinforced by the use of high-quality materials and precision engineering, reflecting {Company Name}'s unwavering commitment to excellence.As a company dedicated to pushing the boundaries of innovation, {Company Name} has invested significant resources in research and development to bring the Separate Slipring Assembly to market. Their team of highly skilled engineers and technical experts have leveraged their expertise to create a product that not only meets the industry standards but also exceeds customer expectations.{Company Name} has a longstanding reputation for delivering high-performance solutions that cater to a wide spectrum of industries, including aerospace, defense, renewable energy, medical technology, and more. Their track record of success is attributed to their relentless pursuit of excellence and their ability to anticipate and address evolving market needs.The introduction of the Separate Slipring Assembly is a testament to {Company Name}'s ongoing commitment to innovation and customer satisfaction. By offering a solution that enhances the performance and reliability of critical systems, they are poised to make a significant impact in the market and set new benchmarks for the industry.Looking ahead, {Company Name} plans to continue investing in research and development to further expand their product portfolio and explore new opportunities for growth. Their dedication to staying at the forefront of technological advancements ensures that they remain a trusted partner for businesses seeking cutting-edge engineering solutions.In conclusion, the launch of the Separate Slipring Assembly marks a significant milestone for {Company Name} and reinforces their position as a leading provider of advanced engineering solutions. With its advanced technology, practical design, and superior performance capabilities, this latest offering is set to make a lasting impact in the industry and meet the evolving needs of customers across various sectors. As {Company Name} continues to drive innovation and set new standards, the future looks promising for their continued success and growth.

Top Slip Ring Manufacturers for Rotating Machinery

Innovative Slip Ring Technology from Trolex EngineeringTrolex Engineering, a leading provider of slip ring technology, has announced the release of its latest range of slip rings. The company, which has been in operation for over 50 years, is renowned for its innovation and expertise in the field of rotary transmission solutions. The new range of slip rings promises to deliver even greater levels of performance and reliability than previous models, cementing Trolex Engineering's reputation as a trusted supplier to a wide range of industries.The new range of slip rings features a number of enhancements over previous models, including improved sealing, increased durability, and expanded capabilities. These new features make the slip rings suitable for a wider range of applications, from heavy-duty industrial machinery to high-precision laboratory equipment.Trolex Engineering has a long history of innovation in slip ring technology. The company was one of the first to incorporate fiber optic technology into its slip rings, paving the way for more efficient data transmission. Today, its slip rings are used in a wide range of applications, from wind turbines to medical equipment.The new slip rings feature Trolex Engineering's patented sealing technology, which provides superior protection against dust, debris, and moisture. The slip rings are also designed to withstand the rigors of heavy use, with materials carefully selected for their durability and resistance to wear and tear.One of the key advantages of Trolex Engineering's slip rings is their versatility. The company offers a wide range of slip rings, each designed to meet the specific needs of different industries and applications. This means that customers can choose a slip ring that is ideally suited to their needs, rather than having to make do with a one-size-fits-all solution.Trolex Engineering has a global reputation for excellence in slip ring technology, and its products are used by companies around the world. The company's team of expert engineers and technicians are committed to delivering the highest standards of quality and reliability, and are constantly working to improve and enhance the company's range of products.The new range of slip rings from Trolex Engineering is a testament to the company's ongoing commitment to innovation and excellence. With enhanced capabilities, improved durability, and expanded versatility, these slip rings are set to become the industry standard in rotary transmission solutions. Whether you're a manufacturer of heavy industrial equipment or a provider of high-tech medical devices, Trolex Engineering's slip rings are sure to meet your needs for years to come.