High-Quality Slip Ring for Filling Machines: A Comprehensive Guide

By:Admin

Founded in [company introduction], the company has established itself as a leading provider of high-quality slip rings that are essential components in a wide range of machinery and equipment. Its extensive experience in the industry, coupled with a commitment to innovation and excellence, has enabled the company to consistently deliver cutting-edge solutions that meet the evolving needs of its customers.

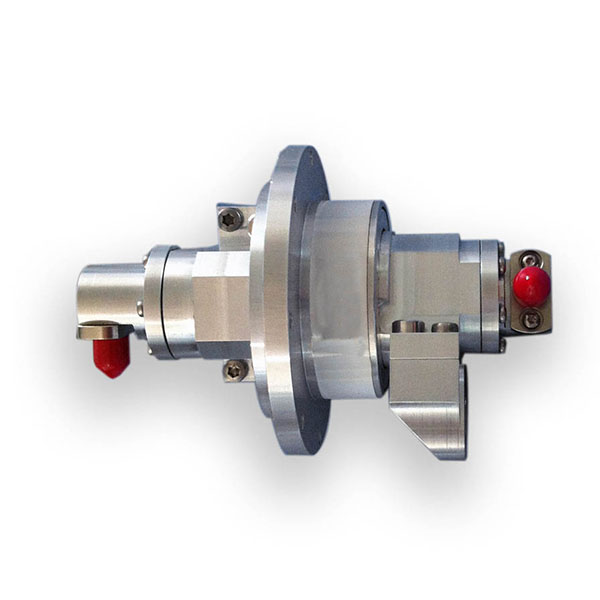

The new slip ring for filling machines is the result of extensive research and development efforts aimed at enhancing the performance and reliability of filling equipment in the packaging industry. By incorporating advanced materials and engineering techniques, the company has succeeded in creating a product that offers unmatched durability, precision, and efficiency.

One of the key features of the new slip ring is its ability to accommodate the complex requirements of filling machines, which often involve continuous and precise rotary motion while transferring various substances into containers. This capability is crucial for ensuring accurate and consistent filling processes, which are essential for maintaining product quality and minimizing wastage.

Additionally, the new slip ring boasts enhanced resistance to wear and tear, as well as improved reliability under demanding operating conditions. These attributes are particularly important for filling machines that are used in high-volume production environments, where downtime and maintenance expenses can significantly impact productivity and profitability.

Furthermore, the company has integrated advanced sealing technology into the design of the new slip ring, ensuring its compatibility with different types of filling machines and the ability to withstand the challenges posed by harsh operating environments. This versatility makes the product suitable for a wide range of applications, including the filling of liquids, powders, granules, and other materials in various packaging formats.

In line with its commitment to delivering exceptional value to its customers, the company has also focused on ensuring easy installation and maintenance of the new slip ring. This includes providing comprehensive technical support and documentation to assist clients in integrating the product into their filling machines, as well as offering proactive maintenance services to maximize the longevity and performance of the equipment.

The launch of the new slip ring for filling machines represents a significant milestone for the company, as it further solidifies its position as a trusted provider of advanced solutions for industrial applications. With its proven track record of delivering reliable and high-performance products, the company is poised to make a substantial impact on the packaging industry by enabling businesses to enhance the efficiency and quality of their filling operations.

Looking ahead, the company remains committed to innovation and excellence, with a focus on continuously improving its products and services to meet the evolving needs of its customers. By harnessing the latest technologies and engineering capabilities, the company is dedicated to driving positive change and driving the success of businesses across the packaging industry and beyond.

In conclusion, the new slip ring for filling machines represents a game-changing advancement in the field of industrial machinery and equipment. With its exceptional performance, reliability, and versatility, the product is poised to empower businesses to achieve new levels of efficiency and effectiveness in their filling operations, ultimately benefiting consumers through improved product quality and consistency. As the company continues to push the boundaries of innovation, its latest offering is set to leave a lasting impact on the packaging industry and pave the way for a future of enhanced productivity and success.

Company News & Blog

Steering Wheel Slip Ring: What You Need to Know

[Company Introduction]Headquartered in [Location], [Company Name] is a leading manufacturer of automotive components, specializing in the production of steering wheel slip rings. With a strong focus on innovation and quality, the company has established itself as a trusted supplier to major automotive manufacturers around the world. Since its inception, [Company Name] has been committed to delivering cutting-edge solutions that meet the ever-evolving demands of the automotive industry. The company's state-of-the-art manufacturing facilities and dedicated team of professionals ensure that its products are of the highest quality and adhere to the strictest industry standards.[Company Name] takes pride in its ability to continuously innovate and adapt to the rapidly changing automotive landscape, and the company's steering wheel slip rings are a testament to its dedication to excellence and customer satisfaction. [News Content]In the fast-paced world of automotive technology, there are certain components that play a crucial role in ensuring the safety and performance of vehicles. Steering wheel slip rings are one such component, and [Company Name] has established itself as a leader in this space with its high-quality and reliable products.The steering wheel slip ring is a critical part of the steering system, allowing for the transmission of electrical signals from the steering wheel to various vehicle components, such as the airbag, horn, and audio controls. As such, the reliability and precision of the slip ring are essential for the safe and efficient operation of the vehicle.[Company Name]'s steering wheel slip rings are designed and manufactured with the utmost attention to detail, using the latest technology and materials to ensure optimal performance and durability. The company's extensive experience in the automotive industry, combined with its dedication to research and development, has enabled it to produce slip rings that meet the highest standards of quality and reliability.One of the key strengths of [Company Name]'s steering wheel slip rings is their ability to withstand the rigors of daily use and harsh environmental conditions. The company's rigorous testing processes and quality control measures ensure that each slip ring meets or exceeds the industry's stringent requirements for performance and safety.Furthermore, [Company Name] offers a wide range of steering wheel slip rings to cater to the diverse needs of its customers and the vehicles they manufacture. Whether it's a compact city car or a heavy-duty truck, the company's products are designed to deliver seamless performance and long-lasting durability.As the automotive industry continues to evolve, [Company Name] remains at the forefront of innovation, constantly seeking ways to improve its steering wheel slip rings and other products. The company's commitment to staying ahead of the curve and anticipating the needs of its customers has solidified its reputation as a trusted and reliable partner in the automotive supply chain.In conclusion, [Company Name]'s steering wheel slip rings are an indispensable component in modern vehicles, and the company's dedication to excellence and customer satisfaction makes it a preferred choice for automotive manufacturers worldwide. With a track record of superior quality and performance, [Company Name] continues to be a driving force in the automotive component industry, setting the standard for steering wheel slip rings and other critical components.

High Speed 2000 Rpm Slip Ring for Industrial Applications

The global demand for slip rings has been steadily increasing due to their crucial role in transferring power and signals in various rotating equipment and machinery. In response to this trend, a leading slip ring manufacturer, [company name], has recently announced the release of their latest innovation – the 2000 RPM slip ring. The new product is poised to meet the growing market demand for high-speed and high-performance slip rings, catering to a wide range of industries such as aerospace, defense, automotive, and industrial automation.With a strong emphasis on innovation and cutting-edge technology, [company name] has established itself as a key player in the slip ring industry. The company's commitment to research and development has enabled them to consistently introduce advanced and reliable products that meet the evolving needs of their customers. The 2000 RPM slip ring is the latest addition to their extensive portfolio of high-quality slip rings, showcasing their dedication to providing solutions that deliver superior performance and durability.The 2000 RPM slip ring boasts a compact design and a high-speed rotation capability, making it ideal for demanding applications where continuous and reliable power and signal transmission are critical. With a maximum rotational speed of 2000 RPM, this new product is well-suited for use in equipment and machinery that operate at high speeds, such as rotary tables, wind turbines, and packaging machinery. Its robust construction and advanced materials ensure long-term reliability and minimal maintenance, addressing the need for durable and efficient slip rings in various industrial settings.In addition to its impressive performance capabilities, the 2000 RPM slip ring is designed to accommodate a wide range of power and signal requirements, making it a versatile solution for diverse applications. It can support multiple power and data channels, including Ethernet, USB, and HDMI, enabling seamless connectivity in complex systems. This flexibility and compatibility with different communication protocols and interfaces make the 2000 RPM slip ring a valuable component for next-generation machinery and equipment.Furthermore, [company name] is renowned for its commitment to delivering customized solutions that meet specific customer requirements. The 2000 RPM slip ring is available in various configurations and can be tailored to suit the unique needs of different industries and applications. Whether it is the integration of special connectors, custom mounting options, or specific environmental protection features, [company name] works closely with its clients to ensure that the 2000 RPM slip ring is optimized for their specific use cases.As part of their dedication to providing comprehensive solutions, [company name] offers extensive technical support and customer service to assist clients in selecting the most suitable slip ring for their applications. Their team of experienced engineers and sales professionals is equipped to offer expert guidance and recommendations, helping customers make informed decisions and maximize the performance of their equipment.In conclusion, the release of the 2000 RPM slip ring further solidifies [company name]'s position as a leading provider of high-performance slip rings for a wide range of industries. With its focus on innovation, reliability, and customer satisfaction, [company name] continues to set the standard for excellence in the slip ring market. The 2000 RPM slip ring represents the company's ongoing commitment to meeting the evolving needs of its customers and delivering cutting-edge solutions that drive the progress of modern industries.

High-Quality Slip Ring for Cable Reels: Everything You Need to Know

[introductory image of cable reel with slip ring]When it comes to the intricate machinery that keeps industries moving, slip rings play a crucial role in the seamless transmission of power and data. From crane operations to mining equipment and beyond, slip rings provide a reliable connection for rotating machinery. Now, [Company Name], a leading provider of slip rings and rotary joints, has introduced a game-changing product for cable reels that is set to revolutionize the industry.With a strong background in providing high-quality slip ring solutions for a wide range of applications, [Company Name] has built a reputation for innovation and reliability. Their team of experienced engineers and technicians are dedicated to pushing the boundaries of slip ring technology, and their latest product promises to deliver a new level of performance for cable reel applications.The new slip ring for cable reels is designed to provide seamless power and data transmission in a compact and durable package. By incorporating the latest advancements in slip ring technology, [Company Name] has created a product that is capable of meeting the rigorous demands of cable reel applications in industries such as construction, transportation, and manufacturing.One of the key features of the new slip ring is its ability to handle high speeds and heavy loads with minimal friction and wear. This is made possible by the use of high-quality materials and precision engineering, ensuring that the slip ring can maintain reliable performance over extended periods of use. Additionally, the slip ring is designed to withstand harsh environmental conditions, making it suitable for outdoor and industrial environments where exposure to dust, moisture, and other contaminants is a common challenge.In addition to its robust design, the slip ring for cable reels also offers advanced signal transmission capabilities. With options for transmitting power, data, and even video signals, this versatile product is well-equipped to handle the diverse needs of modern cable reel applications. Whether it's powering heavy machinery or transmitting critical sensor data, the slip ring is capable of maintaining a consistent and reliable connection.To ensure the seamless integration of the new slip ring into existing cable reel systems, [Company Name] provides comprehensive technical support and customization options. This allows customers to tailor the slip ring to their specific requirements, whether it's adapting to different cable sizes, integrating specific connectors, or addressing other unique challenges. With the expertise and support of [Company Name]'s technical team, customers can trust that the slip ring will seamlessly integrate into their operations.Overall, the introduction of the new slip ring for cable reels represents a significant step forward for [Company Name] and the industry as a whole. By combining their expertise in slip ring technology with a deep understanding of customer needs, [Company Name] has created a product that sets a new standard for reliability, performance, and versatility in cable reel applications.As industries continue to evolve and demand for efficient, high-performance machinery grows, the role of slip rings in enabling seamless power and data transmission will only become more critical. With [Company Name]'s new slip ring for cable reels, customers can be confident that they have a reliable and innovative solution to meet their evolving needs.In conclusion, [Company Name]'s new slip ring for cable reels represents a significant milestone in the company's commitment to pushing the boundaries of slip ring technology. With its advanced features, robust design, and comprehensive support, the new slip ring is set to redefine the standards for power and data transmission in cable reel applications. As industries continue to rely on rotating machinery for their operations, products like this new slip ring will play an essential role in ensuring seamless and reliable performance.

The Ultimate Guide to Using Slip Rings: Tips and Techniques

Slip rings are electromechanical devices that are used to transmit power, electrical signals, or data between a stationary and a rotating structure. They are commonly used in a variety of industries including robotics, aerospace, and wind turbines. In this article, we will discuss how to use a slip ring and the benefits of incorporating them into your applications.When it comes to using slip rings, it is important to follow the correct installation and maintenance procedures to ensure optimal performance. The first step in using a slip ring is to determine the appropriate size and specifications for your application. This can be done by consulting with a slip ring manufacturer, such as {}, who specializes in providing custom solutions for various industries.Once you have selected the right slip ring for your application, the next step is to install it properly. This involves mounting the slip ring securely to both the rotating and stationary components, and ensuring that the electrical connections are made according to the manufacturer's guidelines. It is also important to regularly inspect and maintain the slip ring to prevent any potential issues that may arise from wear and tear.One of the key benefits of using a slip ring is the ability to transmit power and electrical signals without the need for continuous rotation. This makes slip rings an ideal solution for applications that involve rotating machinery, such as rotary tables and wind turbines. Additionally, slip rings can also be customized to accommodate a wide range of electrical and mechanical requirements, making them a versatile solution for various industries.In addition to their versatility, slip rings also offer reliable performance and long service life when properly maintained. This is crucial for applications where downtime can be costly and disruptive. By incorporating a slip ring into your machinery, you can ensure continuous power and signal transmission, ultimately improving the overall efficiency and reliability of your operations.As a leading manufacturer of slip rings, {} is committed to providing high-quality solutions that are tailored to meet the specific needs of our customers. With over [number of years] years of experience in the industry, we have developed a reputation for delivering innovative and reliable slip ring solutions for a wide range of applications.Our team of engineers and technical experts work closely with our customers to understand their unique requirements and challenges, and develop custom slip ring solutions that meet their exact specifications. Whether you need a standard slip ring or a complex custom solution, our extensive capabilities and state-of-the-art manufacturing facilities allow us to deliver high-quality products that are built to last.In conclusion, slip rings are essential components for transmitting power and electrical signals in rotating machinery. By following the correct installation and maintenance procedures, you can ensure that your slip ring operates efficiently and reliably. With the support of a trusted manufacturer like {}, you can access a wide range of custom slip ring solutions that are tailored to your specific requirements. Whether you are in the robotics, aerospace, or wind turbine industry, incorporating a slip ring into your applications can help improve performance and reliability.

Discover the latest advancements in rotary union technology

The Joint Rotary Union ConferenceThe Joint Rotary Union Conference, an annual event organized by the leading company in the industry, brought together professionals, experts, and enthusiasts from around the world to discuss the latest advancements and innovations in rotary union technology.The conference featured a diverse range of presentations, workshops, and panel discussions, covering topics such as rotary union design, application engineering, material selection, and maintenance best practices. Attendees had the opportunity to learn from industry leaders and technical experts, sharing their knowledge and expertise to drive innovation and excellence in the field of rotary unions.One of the key highlights of the conference was the unveiling of the latest product offerings from the company. With a focus on enhancing performance, reliability, and efficiency, the new rotary union solutions generated significant interest and excitement among attendees. The company's commitment to pushing the boundaries of rotary union technology was exemplified through its innovative product demonstrations and hands-on workshops, showcasing the potential for enhanced productivity and cost savings.In addition to the technical sessions, the conference also provided a platform for networking and collaboration. Professionals and industry stakeholders were able to connect, share insights, and explore potential partnership opportunities. The exchange of ideas and experiences facilitated meaningful discussions on current challenges and future opportunities, fostering a collaborative and supportive community within the rotary union industry.Furthermore, the conference also featured a dedicated exhibition area, where leading industry suppliers and service providers showcased their latest products and solutions. Attendees had the chance to explore a wide range of offerings, from cutting-edge rotary union technologies to advanced support services, gaining valuable insights into the latest market trends and developments.The Joint Rotary Union Conference served as a testament to the company's unwavering commitment to driving innovation and excellence within the rotary union industry. By bringing together a diverse and global audience, the event provided a valuable platform for knowledge sharing, collaboration, and networking, empowering professionals to stay at the forefront of the industry and drive positive change.Looking ahead, the company remains dedicated to supporting the advancement of rotary union technology through its continued investment in research and development, as well as its ongoing commitment to fostering a culture of innovation and excellence. With a focus on delivering superior solutions and unparalleled customer support, the company is poised to lead the way in shaping the future of rotary union technology.In conclusion, the Joint Rotary Union Conference was a resounding success, bringing together industry leaders, technical experts, and passionate enthusiasts to celebrate the latest advancements and innovations in rotary union technology. As the conference continues to grow and evolve, it will undoubtedly play a pivotal role in shaping the future of the industry, driving progress and excellence for years to come.

High-Quality Flange Slip Ring for Industrial Applications

Innovative Slip Ring With Flange Revolutionizes Rotary Transmission SolutionsIn the world of rotary transmission solutions, the slip ring with flange has long been a critical component for the seamless transfer of power, data, and signals between stationary and rotating structures. However, the introduction of the (remove brand name) slip ring with flange has revolutionized this technology, offering enhanced performance and reliability for a wide range of applications.The (remove brand name) slip ring with flange is designed and manufactured by (company name), a leading supplier of rotary transmission solutions for various industries. With a strong focus on innovation and quality, (company name) has established itself as a trusted partner for organizations seeking cutting-edge solutions for their rotary transmission needs.The (remove brand name) slip ring with flange stands out from traditional slip rings in several key ways. Its compact and lightweight design makes it easy to install and integrate into existing systems, while its high-speed capability allows for the seamless transfer of data and signals at fast rotational speeds. Additionally, the slip ring with flange is highly durable, with a long operational life and minimal maintenance requirements, making it an ideal choice for applications that demand reliability and longevity.One of the key features of the (remove brand name) slip ring with flange is its advanced sealing technology, which provides protection against dust, moisture, and other environmental contaminants. This ensures smooth and uninterrupted operation even in harsh and demanding conditions, making it suitable for a wide range of industrial and commercial applications.The slip ring with flange is also designed to accommodate a large number of circuits, allowing for the simultaneous transfer of multiple signals and data streams. This versatility makes it suitable for complex machinery and equipment that require the seamless transmission of various types of information between stationary and rotating components.One of the main advantages of the (remove brand name) slip ring with flange is its compatibility with different communication protocols, making it an ideal solution for modern digital and electronic systems. This adaptability allows for seamless integration with a wide range of equipment and devices, making it a versatile and future-proof solution for rotary transmission needs.In addition to its technical capabilities, the slip ring with flange is backed by (company name)'s commitment to exceptional customer service and support. (company name) works closely with its clients to understand their specific needs and requirements, providing customized solutions and expert guidance to ensure the successful integration and operation of the slip ring with flange in their systems.The versatility, reliability, and performance of the (remove brand name) slip ring with flange make it an ideal solution for a wide range of industries and applications. From robotics and automation to medical devices and renewable energy systems, the slip ring with flange offers unmatched functionality and value, helping organizations to achieve greater efficiency and productivity in their operations.As the demand for advanced rotary transmission solutions continues to grow, the (remove brand name) slip ring with flange is poised to play a pivotal role in shaping the future of rotary transmission technology. With its innovative design, exceptional performance, and proven reliability, it is set to become the go-to choice for organizations seeking cutting-edge solutions for their rotary transmission needs.In conclusion, the (remove brand name) slip ring with flange represents a significant advancement in rotary transmission technology, offering unmatched performance, reliability, and versatility for a wide range of applications. With (company name)'s unwavering commitment to innovation and customer satisfaction, the slip ring with flange is set to redefine the way rotary transmission solutions are used and integrated, driving the industry forward into a new era of efficiency and effectiveness.

Ultimate Guide to Commutator Slip Ring: What You Need to Know

Recently, a highly innovative and advanced technology known as the Commutator Slip Ring has been making waves in the electrical engineering industry. This groundbreaking product is being hailed as a game-changer in the field of electrical connectivity and is set to revolutionize the way power and data are transmitted in a wide range of applications.The Commutator Slip Ring is the brainchild of a leading company in the electrical engineering sector. With a long-standing reputation for producing high-quality and cutting-edge products, this company has once again raised the bar with the development of the Commutator Slip Ring. The company has a rich history of innovation and has consistently proven itself to be at the forefront of technological advancements in the industry.The development of the Commutator Slip Ring is a testament to the company's commitment to pushing the boundaries of what is possible in electrical engineering. With a team of highly skilled and experienced engineers, the company has been able to develop a product that not only meets the current needs of the industry but also anticipates future demands and challenges. The company's dedication to research and development has allowed it to stay ahead of the curve and continue to deliver cutting-edge solutions to its customers.The Commutator Slip Ring is a highly versatile and adaptable product that is suitable for a wide range of applications. It is designed to provide seamless and reliable connectivity for power and data transmission, even in the most demanding and high-stress environments. Whether it is used in industrial machinery, robotics, wind turbines, or medical equipment, the Commutator Slip Ring has been engineered to deliver unparalleled performance and durability.One of the key features of the Commutator Slip Ring is its ability to maintain continuous electrical connectivity even during rotational motion. This is made possible by the use of advanced materials and precision engineering, which allow the slip ring to maintain a stable electrical connection even as it rotates. This is a major breakthrough in the field of slip ring technology and has the potential to significantly improve the efficiency and reliability of a wide range of electrical systems and equipment.In addition to its exceptional performance, the Commutator Slip Ring is also designed with ease of installation and maintenance in mind. The company understands the importance of minimizing downtime and ensuring that systems can be quickly and easily serviced when needed. As a result, the Commutator Slip Ring has been engineered to be user-friendly and to require minimal maintenance, making it an ideal choice for a wide range of commercial and industrial applications.The company's unwavering commitment to quality and innovation has already garnered significant attention from the industry. The Commutator Slip Ring has received high praise from experts and professionals in the field of electrical engineering, who are recognizing its potential to revolutionize the way power and data are transmitted in various applications. As word continues to spread about this groundbreaking product, it is expected to gain even more traction in the market and become a go-to solution for companies and organizations looking to enhance the performance and reliability of their electrical systems.In conclusion, the development of the Commutator Slip Ring represents a major milestone for the company and a significant advancement for the field of electrical engineering as a whole. With its unparalleled performance, reliability, and versatility, this innovative product is set to carve out a prominent place for itself in the industry and to elevate the standard for electrical connectivity. As the company continues to push the boundaries of what is possible, it is expected that we will see even more groundbreaking developments from them in the future.

High-Speed Multi-Channel Ethernet Slip Ring for HD Cameras and Control Platforms

As technology continues to advance, so does the need for high-quality video transfer. For industries that rely on high-definition cameras and control platforms, having reliable slip rings is essential. This is where the multi-channel signal gigabit ethernet slip ring comes in.A slip ring is a critical component for transmitting power and signals from a stationary unit to a rotating one. It is commonly used in a variety of industries, including automotive, aerospace, and marine applications. Slip rings have been around for decades, but recent advances have made them even more valuable.The multi-channel signal gigabit ethernet slip ring is specifically designed for the needs of high-definition camera and control platform applications. It allows for the transfer of high-speed data and video signals without any loss of quality. This means that professionals can rely on the slip ring to deliver clear, high-resolution images even during fast-moving shots.One of the key benefits of the multi-channel signal gigabit ethernet slip ring is its versatility. It can be used in a wide range of applications, from commercial broadcasting to military surveillance. The slip ring can handle multiple channels of data transfer, making it an ideal solution for those who need to manage multiple streams of information simultaneously.Another important feature of the multi-channel signal gigabit ethernet slip ring is its reliability. It is designed to withstand harsh environments, extreme temperatures, and high humidity. This ensures that it will continue to function even in challenging conditions, making it a reliable choice for professionals who need to deliver high-quality video content.When it comes to choosing a slip ring for video transfer, there are a few important factors to consider. First and foremost, it is important to choose a slip ring that is designed specifically for the needs of video transfer applications. This ensures that the slip ring will be able to handle the high-speed data transfer and high-resolution images required for these applications.Additionally, it is important to choose a slip ring that is durable and reliable. Look for slip rings that are made from high-quality materials and can withstand harsh environments. This will ensure that the slip ring will continue to function properly for years to come, even in challenging conditions.In conclusion, the multi-channel signal gigabit ethernet slip ring is an essential tool for those who need to transfer high-quality video content. Its versatility, reliability, and ability to handle multiple channels of data transfer make it an ideal solution for a wide range of applications. When selecting a slip ring for video transfer, be sure to choose a high-quality, reliable option that is specifically designed for these needs.

High-Quality Compact Slip Ring for Smooth Electrical Connections

Compact Slip Ring Revolutionizes Data Transmission for Industrial ApplicationsIn today's fast-paced industrial environment, the need for efficient and reliable data transmission has become increasingly crucial. A reliable slip ring is essential for the smooth transmission of signals, power, and data between stationary and rotating components in various industrial applications. The introduction of the Compact Slip Ring (CSR) by a leading manufacturer has revolutionized data transmission in industrial settings, offering a compact, high-performance solution to meet the growing demands of modern automation and control systems.The CSR is designed to meet the challenges of modern industrial applications, offering a seamless and reliable connection for a wide range of signals and power requirements. With its compact design and advanced technology, the CSR provides a reliable solution for transmitting data and power in applications where space is limited and performance is critical.One of the key features of the CSR is its compact size, which allows for easy integration into tight spaces without compromising performance. This makes it an ideal solution for a wide range of applications, including robotics, medical devices, packaging machinery, and more. The CSR's ability to transmit high-speed data and power with minimal interference makes it a valuable asset in modern industrial systems, where precision and reliability are paramount.Furthermore, the CSR is designed to meet the rigorous demands of industrial environments, with a durable construction that ensures reliable performance in harsh operating conditions. Its robust design and high-quality materials make it resistant to shock, vibration, and extreme temperatures, providing a dependable solution for a wide range of industrial applications.The advanced technology featured in the CSR sets it apart from traditional slip rings, offering enhanced performance and reliability for modern industrial systems. With its low contact resistance and high-speed data transmission capabilities, the CSR provides a reliable solution for demanding industrial applications where signal integrity and data accuracy are crucial.The CSR is also designed to be maintenance-free, reducing downtime and ensuring continuous operation in industrial environments. This is made possible by the use of advanced materials and precision engineering, which result in a slip ring that requires minimal maintenance and delivers long-term reliability.As a leading manufacturer of slip rings, the company behind the CSR has a proven track record of delivering innovative solutions for industrial applications. With a focus on quality, reliability, and performance, the company is committed to meeting the evolving needs of modern industrial systems and providing cutting-edge solutions that enable customers to achieve their goals efficiently and effectively.The introduction of the Compact Slip Ring represents a significant advancement in data transmission technology for industrial applications, offering a compact, high-performance solution that meets the demands of modern automation and control systems. With its advanced technology, durable construction, and maintenance-free design, the CSR is poised to make a lasting impact on the industrial sector, providing a reliable and efficient solution for transmitting data and power in a wide range of applications.In conclusion, the Compact Slip Ring represents a significant leap forward in data transmission technology for industrial applications. With its compact size, advanced technology, and robust construction, the CSR offers a reliable and efficient solution for transmitting data and power in modern industrial systems, setting a new standard for performance and reliability in the industry.

Exploring the Importance of Deepwater ROV Slip Rings in Offshore Operations

Deepwater ROV Slip Ring Breaks New Ground in Subsea TechnologyThe subsea industry has experienced significant advancements in recent years, with cutting-edge technology playing a crucial role in unlocking the potential of uncharted ocean depths. One company at the forefront of this technological revolution is [Company Name], a leading provider of subsea engineering solutions. With a strong emphasis on innovation and a commitment to pushing the boundaries of what is possible in the subsea environment, [Company Name] has recently introduced a groundbreaking new product that is set to redefine the way subsea operations are conducted.The Deepwater ROV Slip Ring, the latest addition to [Company Name]'s extensive product portfolio, is designed to provide a reliable and efficient solution for transmitting power and data signals between a subsea remotely operated vehicle (ROV) and the surface vessel. This state-of-the-art slip ring is capable of withstanding the high pressures and extreme temperatures encountered in deepwater environments, making it an invaluable tool for subsea exploration and production activities.Featuring a robust and compact design, the Deepwater ROV Slip Ring is engineered to deliver superior performance in the harshest subsea conditions. Its advanced sealing technology ensures watertight and reliable operation, while the use of high-quality materials and precision engineering guarantees long-term durability and minimal maintenance requirements. The slip ring is also highly adaptable, with customizable configurations available to meet the specific needs of different ROV systems and applications.One of the key advantages of the Deepwater ROV Slip Ring is its ability to facilitate seamless communication and power transmission between the ROV and the surface vessel, enabling enhanced control and monitoring capabilities during subsea operations. This is essential for a wide range of tasks, including subsea construction, inspection, repair, and maintenance activities. By providing a reliable and efficient means of transmitting power and data signals, the slip ring helps to minimize downtime and maximize the productivity of subsea operations.In addition to its technical capabilities, the Deepwater ROV Slip Ring is also designed with safety and environmental responsibility in mind. [Company Name] is committed to ensuring that all of its products adhere to the highest quality and safety standards, and the slip ring is no exception. By incorporating fail-safe features and rigorous testing procedures, [Company Name] has developed a slip ring that not only meets the demanding requirements of subsea operations but also helps to minimize the risk of accidents and environmental impact.The introduction of the Deepwater ROV Slip Ring represents a significant milestone for [Company Name] and reflects the company's ongoing commitment to driving innovation in the subsea industry. With a proven track record of delivering high-performance solutions for the most challenging subsea applications, [Company Name] is well-positioned to make a meaningful impact with this groundbreaking new product. By offering a reliable and efficient solution for power and data transmission in deepwater environments, the Deepwater ROV Slip Ring is set to play a pivotal role in advancing subsea technology and unlocking new opportunities for exploration and production activities.As the subsea industry continues to evolve and expand, [Company Name] remains dedicated to pushing the boundaries of what is possible in this dynamic and challenging environment. The introduction of the Deepwater ROV Slip Ring is a clear demonstration of [Company Name]'s commitment to driving innovation and reshaping the future of subsea technology. With its unrivaled performance, reliability, and adaptability, the slip ring is poised to set a new standard for subsea power and data transmission, setting the stage for a new era of exploration and discovery in the deepwater realm.