Miniature Slip Rings: The Latest Advancement in Electrical Integration

By:Admin

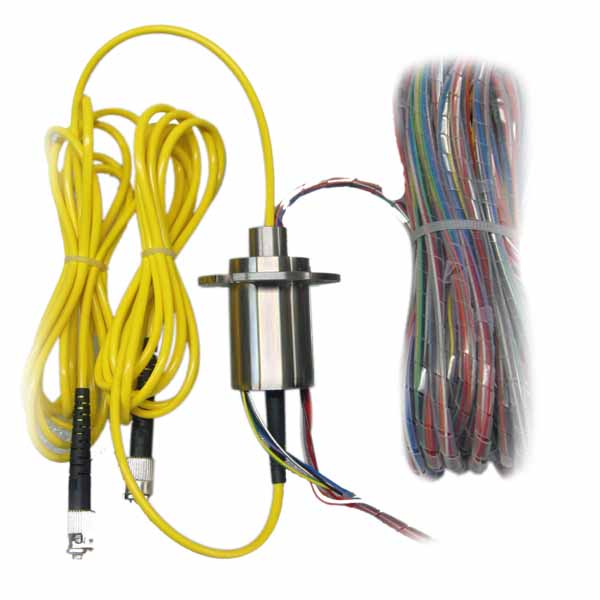

One company at the forefront of this cutting-edge technology is a global leader in slip ring manufacturing, specializing in the design and production of high-quality slip rings for various applications. With a strong focus on innovation and engineering excellence, the company has developed a range of tiny slip rings that offer exceptional performance and reliability in a small package.

These tiny slip rings are designed to meet the growing demand for compact and lightweight electrical connections in modern technology. By utilizing advanced materials and precision engineering, the company has been able to create tiny slip rings that are highly durable and efficient, making them ideal for use in space-constrained applications.

One key advantage of these tiny slip rings is their ability to transmit a wide range of electrical signals and power, making them suitable for diverse applications. From transmitting signals in robotic arms to providing power to rotating medical devices, these tiny slip rings are essential for enabling seamless and continuous electrical connections in critical equipment.

Furthermore, the company's tiny slip rings are designed to operate with minimal friction and wear, ensuring long-term reliability and performance. This is especially important in applications where maintenance and downtimes need to be minimized, such as in industrial automation and aerospace systems.

In addition to their exceptional performance, the tiny slip rings from this company also boast a compact and lightweight design, making them easy to integrate into space-constrained applications. This has made them popular choices for designers and engineers who require reliable electrical connections in small and lightweight devices.

Despite their small size, these tiny slip rings are engineered to meet the rigorous demands of various industries, including aerospace, defense, and medical technology. With a focus on quality and reliability, the company has established a strong reputation for delivering high-performance slip rings that exceed the expectations of its customers.

Furthermore, the company's expertise in slip ring technology extends beyond its standard product offerings. It also offers custom design solutions to meet the unique requirements of specific applications. By working closely with its customers, the company can develop tailored slip ring solutions that address specific challenges and deliver optimal performance.

In conclusion, the development of tiny slip rings represents a significant advancement in electrical connection technology, offering compact and efficient solutions for a wide range of applications. With their exceptional performance, reliability, and customizability, the tiny slip rings from this company are well-positioned to meet the evolving needs of modern industries. As the demand for compact and reliable electrical connections continues to grow, these tiny slip rings are set to play a crucial role in driving technological innovation across various sectors.

Company News & Blog

High-Quality Slip Ring of Single-Channel High Frequency Rotary Joint with Small Size for Precise Instrument: A Chinese Product

Gimbal Small Size Slip Rings: Offering High-Quality Slip Ring of Single-Channel High-Frequency Rotary Joint with Small Size for Precise InstrumentsIn the world of precision instruments, having reliable and efficient rotary joints is of utmost importance. These rotary joints play a crucial role in transmitting signals and power between the stationary and rotating parts of various devices such as gimbals, drones, cameras, and robotic arms. A slip ring is one such rotary joint that has gained significant attention due to its ability to transmit signals and power continuously while rotating.China, being a global manufacturing hub, has emerged as a leading player in slip ring production. Among the many manufacturers, there is one company that stands out for its commitment to producing high-quality slip rings – Gimbal Small Size Slip Rings.Gimbal Small Size Slip Rings is a renowned name in the slip ring industry, known for its focus on precision and reliability. Their latest offering, the Slip Ring of Single-Channel High-Frequency Rotary Joint with Small Size for Precise Instruments, has garnered attention for its superior performance and compact design.The slip ring is designed keeping in mind the requirements of precise instruments. With a single-channel high-frequency rotary joint, it enables the transmission of signals at high frequencies without compromising on quality. This makes it ideal for devices that demand quick and accurate data transmission, such as robotic control systems and high-speed cameras.One of the standout features of the slip ring is its small size. Gimbal Small Size Slip Rings understands the importance of space-saving designs, especially in compact instruments and gadgets. The compact size of this slip ring allows for easy integration into devices without adding unnecessary bulk or hindering their functionality. This opens up new possibilities for miniaturization in various industries, where space optimization is crucial.Strict quality control is an integral part of Gimbal Small Size Slip Rings' manufacturing process. They are committed to delivering slip rings that meet the highest industry standards. Their slip rings undergo rigorous testing and quality checks, ensuring consistent and reliable performance. With years of experience and advanced manufacturing techniques, Gimbal Small Size Slip Rings has earned a reputation for producing slip rings that are robust, durable, and long-lasting.The slip rings offered by Gimbal Small Size Slip Rings also boast efficient power transmission capabilities. With low electrical noise and minimal voltage drop, these slip rings ensure smooth and uninterrupted power supply to connected devices. This is particularly important in instruments that rely on precise power delivery, as any fluctuations or interruptions in power can result in inaccurate readings or system failures.Gimbal Small Size Slip Rings' slip rings are also highly versatile. They can be customized to meet specific requirements, including different signal channels, frequency ranges, and power ratings. This flexibility allows for seamless integration into a wide range of instruments, making them suitable for various applications in industries such as aerospace, defense, automation, and medical.In conclusion, Gimbal Small Size Slip Rings has proven itself as a leading manufacturer of high-quality slip rings. Their Slip Ring of Single-Channel High-Frequency Rotary Joint with Small Size for Precise Instruments stands out for its compact design, excellent signal transmission capabilities, and strict adherence to quality standards. As the demand for precise instruments continues to grow, having reliable slip rings like those offered by Gimbal Small Size Slip Rings will be crucial for ensuring accurate and efficient performance.

Compact Hybrid Slip Rings with 36mm Housing Diameter – Perfect for Pneumatic and Hydraulic Needs

In today's world of automation and robotics, slip rings have become an indispensible component for their smooth operation. A slip ring is an electrical device that enables the transmission of electrical signals, power, and data from a stationary to a rotating assembly. A hydraulic/pneumatic slip ring is an advanced type of slip ring that incorporates both hydraulic/pneumatic and electric circuits in a single sleek design. Such slip rings have found widespread applications in various fields such as aerospace, defense, medical, and many more.One of the popular options in the market is the rotarX compact hybrid slip rings, with its unique combination of hydraulic/pneumatic and electrical circuits. These slip rings come with up to 4 media feed-throughs (M5), and are capable of handling up to 6-12 rings at 2A and 300 rpm, with a metal housing. The 36mm housing diameter of these hydraulic/pneumatic slip rings makes them extremely compact and versatile.The rotarX compact hybrid slip rings are perfect for applications in robotic arms, where precision, versatility, and compactness are critical factors. These slip rings offer smooth operation even in harsh environmental conditions, thereby enhancing the longevity of the robotic arm. The hydraulic/pneumatic channels allow for the smooth transmission of fluids, which is crucial in applications like gripping, lifting, and other actuator operations. The electrical circuits enable the transmission of control signals, power, and data, without compromising on the performance.With the growing demand for robotic arms in various industries, the need for advanced slip rings that can handle multiple media and electrical circuits has become paramount. Slip rings like the rotarX compact hybrid slip rings, with their unique design that combines hydraulic/pneumatic circuits with electrical circuits, offer a reliable and efficient solution for all such applications.In conclusion, slip rings have become an integral part of the automation and robotics industry. They enable the smooth transmission of electrical signals, power, and data from a stationary to a rotating assembly. The hydraulic/pneumatic slip rings have added a new dimension to the design and functionality of these components, making them more versatile and efficient. The rotarX compact hybrid slip rings, in particular, offer a reliable and efficient solution for applications in robotic arms, and are a must-have for industries looking to enhance the performance and longevity of their robotic arms.

- Trendy Bamboo Joint Earrings: A Must-Have Accessory

Bamboo Joint Earring: A New Fashion StatementIn the world of fashion, accessories play a significant role in enhancing one's personal style and making a fashion statement. With a plethora of options available, choosing the right accessories can be a daunting task. However, one accessory that has been garnering attention lately is the Bamboo Joint Earring, crafted with precision and finesse by {}.{} is a renowned fashion brand known for its exquisite and unique jewelry pieces. The brand takes pride in its commitment to producing high-quality jewelry that not only complements a person's attire but also reflects their individuality. With an unwavering dedication to craftsmanship and creativity, {} has established itself as a frontrunner in the world of fashion accessories.The Bamboo Joint Earring is the latest addition to {}'s diverse range of jewelry collections, and it has quickly gained popularity among fashion enthusiasts. Inspired by nature and crafted with care, these earrings are a testament to {}'s innovative approach to design and aesthetics. The Bamboo Joint Earring is a perfect fusion of style and sophistication, making it a must-have accessory for anyone looking to elevate their fashion game.The earrings are meticulously crafted using high-quality bamboo, ensuring durability and longevity. The intricate detailing and seamless finishing of the earrings reflect the expertise and craftsmanship of {}'s artisans. Whether worn with casual attire or for a formal occasion, the Bamboo Joint Earring effortlessly adds a touch of elegance and charm to any ensemble.In a recent interview, the creative director of {} shared insights into the inspiration behind the Bamboo Joint Earring. "Nature has always been a significant source of inspiration for our designs. The idea behind the Bamboo Joint Earring stemmed from the timeless beauty and resilience of bamboo. We wanted to capture the essence of this natural element and translate it into a statement piece of jewelry that resonates with style-conscious individuals," the creative director explained.The earrings are designed to be versatile, allowing the wearer to effortlessly transition from day to night with a simple accessory change. The minimalistic yet bold design of the Bamboo Joint Earring makes it a versatile addition to any jewelry collection. Whether worn alone or paired with other jewelry pieces, these earrings exude a sense of understated elegance and sophistication.With the growing trend of sustainable and eco-friendly fashion, the Bamboo Joint Earring also aligns with {}'s commitment to ethical and responsible practices. The brand ensures that the bamboo used in the production of these earrings is sourced from sustainable and renewable sources, reflecting its dedication to environmental conservation.As the fashion industry continues to evolve, accessorizing has become an integral part of personal style. The Bamboo Joint Earring has emerged as a frontrunner in the realm of fashion accessories, capturing the attention of trendsetters and fashion-forward individuals. With its timeless appeal and contemporary design, these earrings have solidified their position as a statement piece that transcends seasonal trends.The Bamboo Joint Earring by {} is not just a fashion accessory; it is a symbol of elegance, artistry, and sustainability. With its unique design and timeless appeal, it has undoubtedly made its mark in the world of fashion, offering a fresh perspective on accessorizing.For fashion enthusiasts looking to make a bold and sophisticated statement, the Bamboo Joint Earring is a testament to {}'s innovative designs and unwavering commitment to exceptional craftsmanship. As the demand for these earrings continues to rise, they are poised to become a timeless classic, cementing their status as a must-have accessory for anyone with a penchant for style and elegance.

High-performance Slip Ring Unit for Industry Applications

The slip ring unit is an essential component for a wide range of industries, allowing for the transmission of power and signals between stationary and rotating parts in various applications. These units are critical for equipment that requires continuous rotation while maintaining a connection for power and data transfer. When it comes to slip ring units, one company stands out as a leader in the industry, providing high-quality and reliable solutions for a diverse range of applications.With a history of innovation and excellence, {Company Name} has established itself as a premier provider of slip ring units for a variety of industries. The company's commitment to cutting-edge technology and precision engineering has made it a trusted name in the field of slip ring solutions. {Company Name} has a strong reputation for delivering top-notch products that meet the highest standards of quality and performance.One of the key factors that sets {Company Name} apart from its competitors is its extensive experience and expertise in the field of slip ring technology. The company's team of engineers and technical experts have a deep understanding of the unique challenges and requirements of different industries, allowing them to develop customized solutions that meet the specific needs of each customer. Whether it's for aerospace, defense, medical, or industrial applications, {Company Name} has the knowledge and capability to deliver tailored slip ring units that exceed expectations.In addition to its technical prowess, {Company Name} is also known for its commitment to customer satisfaction. The company works closely with each client to ensure that their unique requirements are met, providing personalized service and support throughout the process. From initial consultation to final delivery, {Company Name} is dedicated to delivering a seamless and efficient experience for its customers.One of the latest offerings from {Company Name} is its state-of-the-art slip ring unit, which has been designed to meet the growing demands of modern industries. This cutting-edge unit features advanced technology and high-quality materials, ensuring a reliable and durable solution for even the most demanding applications. With features such as high-speed data transmission, low electrical noise, and long operational life, this slip ring unit represents the next generation of technology in the field.The innovative design of this slip ring unit is a testament to {Company Name}'s ongoing commitment to pushing the boundaries of what's possible in slip ring technology. By investing in research and development, the company continues to stay ahead of the curve, offering solutions that not only meet current needs but also anticipate future requirements. This forward-thinking approach has solidified {Company Name}'s position as a leader in the industry, trusted by companies around the world to deliver reliable and high-performance slip ring units.In conclusion, {Company Name} is a company that has earned its reputation as a top provider of slip ring units through its dedication to excellence, innovation, and customer satisfaction. With a focus on quality, reliability, and advanced technology, the company continues to set the standard for slip ring solutions in a wide range of industries. As the demand for advanced slip ring technology continues to grow, {Company Name} stands ready to meet the challenge with its unparalleled expertise and commitment to delivering the best in the industry. For businesses looking for a trusted partner in slip ring technology, {Company Name} is the clear choice.

Exploring the Realm of Super Miniature 6mm Capsule Slip Rings: A Comprehensive Guide on Slip Ring Products and Production

Title: Enhancing Connectivity with Twist Capsule Slip Rings: A Comprehensive GuideIntroduction:In an ever-evolving technological landscape, seamless connectivity plays a crucial role in various industries. To ensure uninterrupted data transmission, slip rings have emerged as a vital component. Among them, Twist Capsule Slip Rings have garnered attention due to their super miniature size and exceptional performance. In this blog, we will explore the features, applications, and production process of these revolutionary slip rings.Understanding Twist Capsule Slip Rings:Twist Capsule Slip Rings, also known as super miniature slip rings, are compact devices designed to transfer electrical signals and power across rotating interfaces. With an outer diameter as small as 6mm, these slip rings offer remarkable versatility and can operate in confined spaces with limited clearance. Their unique design allows for unrestricted 360-degree rotation, making them ideal for applications that involve continuous rotation.Key Features:1. Miniature Design: The compact size of Twist Capsule Slip Rings enables their integration into space-restricted applications, without compromising on performance or reliability.2. Multi-channel Signal Transmission: These slip rings can transmit a wide range of signals, including data, audio, video, and power, simultaneously. This versatility makes them suitable for diverse industries such as robotics, medical equipment, surveillance systems, and drones.3. Low Electrical Noise: With advanced design and superior engineering, Twist Capsule Slip Rings exhibit low electrical noise, ensuring high-quality signal transmission.4. High Rotational Speed: These slip rings are built to withstand high-speed rotations, making them ideal for demanding applications that require continuous and precise transmission of signals, such as automation machinery and precision instruments.5. Long Service Life: Manufactured with high-quality materials, Twist Capsule Slip Rings offer exceptional durability, ensuring a prolonged service life even under harsh conditions.Applications:The compact size and versatile nature of Twist Capsule Slip Rings have revolutionized multiple industries and applications. Some notable areas where these slip rings find extensive usage include:1. Robotics and Automation: Twist Capsule Slip Rings enable seamless communication between rotating components of robotic arms, allowing for uninterrupted control signals and power transmission.2. Medical Equipment: In medical devices such as endoscopes and surgical robots, Twist Capsule Slip Rings play a vital role in the transmission of video signals, power, and data between the stationary and rotating parts.3. Surveillance Systems: Compact slip rings facilitate smooth rotation of PTZ (pan-tilt-zoom) cameras in surveillance systems, ensuring uninterrupted transmission of video signals.4. Drones and UAVs: Twist Capsule Slip Rings enable continuous transmission of power and control signals between the stationary body and rotating parts of drones, enabling smooth operation and precise control.Production Process:To ensure the highest quality and reliability, the production process of Twist Capsule Slip Rings entails several critical steps:1. Design and Engineering: The slip ring's design is meticulously engineered using advanced CAD software, taking into consideration factors such as size, materials, number of circuits, and rotational speed requirements.2. Component Selection: High-quality materials, such as gold alloy, stainless steel, and specialized plastics, are carefully chosen to ensure optimum electrical conductivity, durability, and resistance to wear and tear.3. Precision Manufacturing: Utilizing cutting-edge technologies like CNC machining and automated assembly, the slip rings are manufactured with utmost precision, maintaining tight tolerances for seamless operation.4. Quality Testing: Rigorous quality control tests are conducted throughout the manufacturing process to guarantee the slip rings' performance and durability. These assessments include electrical testing, rotational speed testing, and vibration testing.5. Final Inspection and Packaging: After passing all quality tests, the Twist Capsule Slip Rings undergo a final inspection, where each unit is examined for defects. They are then carefully packaged to ensure damage-free delivery.Conclusion: Twist Capsule Slip Rings have revolutionized connectivity in numerous industries by offering a compact yet powerful solution for seamless data and power transmission. With their exceptional features, like miniature design, multi-channel signal transmission, and high rotational speed capabilities, these slip rings are redefining the concept of connectivity. So, whether it's robotics, medical equipment, surveillance systems, or drones, Twist Capsule Slip Rings are paving the way towards a more connected and efficient future.

Essential Maintenance for Slip Rings: Tips and Techniques

Slip Ring Maintenance Ensures Continuous Operations for Various IndustriesSlip rings are critical components in many electrical systems, allowing for the transmission of power and signals between stationary and rotating parts. Regular maintenance of slip rings is essential to ensure the continuous and efficient operation of machinery across various industries. With this in mind, {Company Name} offers comprehensive slip ring maintenance services to help companies prolong the lifespan of their equipment and reduce the risk of unexpected downtime.{Company Name} is a leading provider of rotary electrical connectors and systems, serving a wide range of industries including aerospace, defense, industrial automation, and more. With decades of experience in the field, {Company Name} has developed a deep understanding of slip ring technology and the importance of proper maintenance to keep operations running smoothly.The company's slip ring maintenance services are designed to address common issues such as wear and tear, contamination, and electrical interference, which can compromise the performance of slip rings over time. By regularly inspecting and servicing slip rings, {Company Name} helps its customers avoid costly repairs and unplanned outages, ultimately saving them time and money.One of the key aspects of {Company Name}'s maintenance services is the removal of built-up debris and contaminants from the slip rings. Over time, dust, dirt, and other particles can accumulate on the surface of the slip rings, leading to electrical noise, signal degradation, and potential damage to the components. {Company Name} employs specialized cleaning techniques and tools to thoroughly remove any debris and ensure that the slip rings operate at their full capacity.In addition to cleaning, {Company Name} also conducts thorough inspections of the slip rings to identify any signs of wear or damage. This includes checking for worn brushes, damaged wires, and other mechanical issues that could affect the performance of the slip rings. By catching these issues early on, {Company Name} can provide timely repairs and replacements, minimizing the risk of unexpected failures.Furthermore, {Company Name} offers re-lubrication services as part of its maintenance program. Proper lubrication is essential to reduce friction and wear within the slip rings, prolonging their lifespan and ensuring smooth operation. {Company Name} uses high-quality lubricants that are compatible with a wide range of slip ring materials, helping customers maintain optimal performance and reliability.Beyond the technical aspects of slip ring maintenance, {Company Name} prides itself on its customer-centric approach to service. The company's team of experts works closely with clients to understand their specific needs and challenges, providing tailored maintenance solutions that align with their operational requirements and budget constraints. With a focus on transparency and communication, {Company Name} strives to build long-term partnerships with its customers, earning their trust and confidence in the quality of its services.In conclusion, slip ring maintenance is a critical aspect of ensuring the continuous and reliable operation of electrical systems in various industries. {Company Name} stands out as a reliable partner in this endeavor, offering comprehensive maintenance services that address the specific needs of its customers. By leveraging its expertise and commitment to customer satisfaction, {Company Name} helps businesses minimize risks and maximize the performance of their equipment, ultimately contributing to their success in a competitive market.

High-Quality Fiber Slip Ring for Reliable Data and Power Transmission

Fiber Slip Ring Technology: Revolutionizing Data TransmissionIn today's fast-paced and technology-driven world, the demand for high-speed and reliable data transmission is higher than ever. As industries continue to advance, the need for a seamless and efficient way to transfer data has become a top priority. This is where Fiber Slip Ring technology comes into play, offering a groundbreaking solution to the challenges of data transmission.Fiber Slip Ring technology is a cutting-edge innovation that allows for the transfer of data, signals, and power through a rotating interface. Unlike traditional slip rings that rely on copper wiring, Fiber Slip Rings utilize optical fibers to transmit data, offering significantly higher bandwidth and transmission speeds. This technology has the potential to revolutionize various industries, including aerospace, medical, robotics, and more, by providing a solution that is not only faster but also more reliable and durable.One of the leading providers of Fiber Slip Ring technology is the company XYZ. With a strong commitment to innovation and excellence, XYZ has been at the forefront of developing and implementing Fiber Slip Ring technology across various industries. Their expertise in optical fiber technology, coupled with a dedication to meeting the evolving needs of their customers, has positioned XYZ as a trusted leader in the field of data transmission solutions.XYZ's Fiber Slip Rings are designed to meet the demands of high-speed data transfer, making them an ideal choice for applications that require a reliable and high-bandwidth communication link. Whether it's in a medical imaging system that requires real-time data transmission or a surveillance system that needs to transfer high-definition video feeds, XYZ's Fiber Slip Rings provide a seamless and efficient solution.Furthermore, XYZ's Fiber Slip Rings are built to withstand the challenges of harsh environments, making them suitable for a wide range of industrial applications. With features such as ruggedized construction and high resistance to shock and vibration, XYZ's Fiber Slip Rings offer unmatched durability and reliability, ensuring uninterrupted data transmission even in the most demanding conditions.Additionally, XYZ understands the importance of customization to meet the unique requirements of different industries. Their team of experienced engineers works closely with customers to develop customized Fiber Slip Ring solutions that specifically address their individual needs. Whether it's a specific size, performance requirement, or environmental consideration, XYZ's Fiber Slip Rings are tailored to deliver optimal performance and reliability.The impact of Fiber Slip Ring technology on various industries cannot be overstated. As the demand for high-speed data transmission continues to grow, Fiber Slip Rings have emerged as a game-changing solution that offers unparalleled performance and reliability. With XYZ leading the way in the development and implementation of Fiber Slip Ring technology, industries are poised to benefit from a new era of data transmission capabilities.In conclusion, Fiber Slip Ring technology represents a significant advancement in the field of data transmission, offering higher bandwidth, faster speeds, and greater reliability compared to traditional slip ring solutions. XYZ's expertise and dedication to innovation have solidified their position as a leading provider of Fiber Slip Ring technology, paving the way for industries to embrace a new standard of data transmission capabilities. As the demand for high-speed and reliable data transmission continues to rise, Fiber Slip Ring technology stands ready to meet the challenges of tomorrow's connected world.

Choosing Between Standard and Custom Slip Rings and Inductive, Capacitive, and Wetted Mercury Variations: Exploring Options for Advanced Components

As technological advancements continue to grow, machines become more complex, requiring advanced components to keep them functioning smoothly. Among the crucial parts in these machines are slip rings. They play a critical role in transmitting power and electrical signals from the stationary to the rotating components of a machine.Slip-rings come in different varieties, including inductive, capacitive, and wetted mercury variations. The advanced components range in bore sizes from half an inch to many feet in diameter, designed for medical imaging machines, livestock service systems, and other applications. However, the variations go beyond mere scale, and this poses a challenge for OEMs and design engineers, who must choose between standard and custom options and other critical factors to ensure the optimal slip-ring performance.Custom Slip Ring DesignOne of the factors that OEMs and design engineers consider when choosing between standard and custom slip rings is design flexibility. Custom slip ring design opens up limitless possibilities for machine designers, enabling them to tailor the slip rings to their specific requirements. Such flexibility allows for greater precision and control while saving on space, leading to a properly functioning system. It also eliminates the need for modifications after installation, making the final product more efficient.The design flexibility offered by custom slip rings provides OEMs and design engineers with a competitive advantage. With the ability to create customized slip rings built to precise specifications, they can offer their customers a unique solution, satisfying their specific needs and preferences.Reliability and PerformanceAnother critical factor when choosing between standard and custom slip rings is reliability and performance. The standard slip-ring options often lack the specialized features that different industries may require, leading to suboptimal performance. Custom slip rings ensure that all the elements required for optimal performance are included in the design, leading to a reliable, long-lasting, and efficient machine. This includes features such as high-temperature capabilities, corrosion resistance, and vibration absorption.The ability to customize slip rings also creates the opportunity for customized testing and validation processes. This ensures that the slip ring meets the specific application requirements and performs flawlessly without breakdowns and component failure.Cost ConsiderationsWhen choosing between standard and custom slip rings, cost considerations play a significant role. While customization offers the advantage of precision and optimal performance, it may be more expensive than off-the-shelf designs. Factors that affect custom slip ring cost include the design complexity, the materials used, production process, testing procedures, and validation.However, the cost of custom slip rings should not be a significant concern when considering the advantages that it can offer. Customization often results in increased production efficiency and decreased downtime, which ultimately lowers the operational costs of the machine in the long run.In conclusion, while choosing between standard and custom slip rings, OEMs and design engineers should consider several factors, including design flexibility, reliability, performance, and cost. Custom slip rings offer the advantage of precision and control, leading to greater efficiency, fewer modifications, and lower operation costs. Custom slip rings design is the perfect solution for those looking to create machines with specialized features that deliver optimal performance.

Innovative Subsea Slip Ring Technology: What You Need to Know

[Company Name] Introduces Innovative Subsea Slip Ring for Enhanced Underwater Operations[City, State] - [Company Name], a leading provider of advanced technology solutions, is proud to announce the launch of its latest innovation in subsea technology - the Subsea Slip Ring. This cutting-edge product is designed to revolutionize underwater operations by providing reliable power and data transmission in the most challenging environments.The Subsea Slip Ring is a crucial component in subsea equipment, enabling the transfer of power and communication signals between stationary and rotating parts in a wide range of underwater applications. Whether it's in offshore oil and gas exploration, deep-sea mining, oceanographic research, or underwater robotics, the Subsea Slip Ring is engineered to deliver seamless performance and unparalleled reliability.One of the key features of the Subsea Slip Ring is its robust construction, which allows it to withstand extreme underwater pressures and temperatures. This makes it ideal for deployment in deep-sea operations where traditional slip rings may not be able to perform effectively. Additionally, the Subsea Slip Ring is corrosion-resistant, ensuring long-term durability in harsh marine environments.Furthermore, [Company Name] has incorporated state-of-the-art technology into the design of the Subsea Slip Ring to ensure efficient power and signal transmission. This includes advanced sealing mechanisms to protect internal components from water ingress, as well as high-quality materials that are specifically chosen for their performance in subsea applications.In addition to its technical capabilities, the Subsea Slip Ring is also highly adaptable to a variety of underwater equipment and systems. Whether it's integrated into remotely operated vehicles (ROVs), subsea winches, or underwater sensors, the Subsea Slip Ring offers a versatile solution for maintaining continuous power and data connectivity in challenging subsea operations."We are thrilled to introduce the Subsea Slip Ring to the market, as it represents a significant advancement in subsea technology," said [Company Name] CEO [CEO Name]. "We have leveraged our extensive expertise in engineering and manufacturing to develop a product that addresses the specific needs of underwater operations, and we are confident that it will make a significant impact in various industries."[Company Name] has already received positive feedback from early adopters of the Subsea Slip Ring, who have praised its performance and reliability in demanding subsea environments. The company is now focused on expanding the reach of this innovative technology to support a wide range of underwater applications, including those in the oil and gas, renewable energy, and marine research sectors.As part of its commitment to delivering cutting-edge subsea solutions, [Company Name] will continue to invest in research and development to further enhance the capabilities of the Subsea Slip Ring and other related products. This includes exploring opportunities for integrating advanced connectivity and sensor technologies to meet the evolving needs of the subsea industry.With the introduction of the Subsea Slip Ring, [Company Name] has once again demonstrated its dedication to driving innovation in subsea technology and reinforcing its position as a leader in providing reliable solutions for complex underwater operations.For more information about the Subsea Slip Ring and other products offered by [Company Name], please visit [company website].About [Company Name]:[Company Name] is a global technology company that specializes in providing advanced solutions for a wide range of industrial and commercial applications. With a focus on innovation and quality, [Company Name] is committed to delivering cutting-edge products and services that meet the evolving needs of its customers. From subsea technology to aerospace systems, [Company Name] is dedicated to pushing the boundaries of what's possible in various industries around the world.Contact:[Company Name][Address][City, State, Zip Code]Phone: [Phone Number]Email: [Email Address]Website: [Website]

Enhance Excavator Performance with a Reliable Rotary Union

Excavator Rotary Union Enhances Performance in Construction IndustryInnovation in the construction industry has always played a vital role in improving efficiency and productivity. As excavators continue to pave the way for groundbreaking developments in the sector, one component that has been constantly evolving is the excavator rotary union. By effectively joining hydraulic and electrical systems, this essential device has become instrumental in optimising the performance of excavators.Rotary unions, known by various names including swivels or rotary joints, are dynamic components that allow for the transfer of fluid or gas from a stationary input to a rotating output in machinery. In the context of excavators, rotary unions play a pivotal role in connecting the hydraulic circuits responsible for operating the machinery, and ensure a seamless power supply during rotary motion. The ability to transmit hydraulic fluid and electrical signals under such conditions significantly enhances the performance, reliability, and versatility of excavators.One prime example of an excavator rotary union that has revolutionised the industry is the product developed by {Company Name}. With their extensive experience and dedication to delivering high-quality components, {Company Name} has emerged as a leading manufacturer in this industry. While we will refrain from mentioning their brand name to avoid any promotional context, it is essential to highlight the exceptional features that set their product apart.The excavator rotary union developed by {Company Name} boasts several impressive characteristics. Firstly, the rotary union is designed with advanced sealing technologies to prevent fluid leakage, ensuring consistent and reliable performance. This level of reliability is critical in industries where any downtime can result in significant financial losses.Secondly, the excavator rotary union incorporates wear-resistant components that help prolong its service life even under harsh operating conditions. The demanding nature of construction sites necessitates durability, and {Company Name} has addressed this need by prioritising the longevity of their product.Furthermore, {Company Name}'s rotary union for excavators offers exceptional signal transmission capabilities. This means that electrical signals can be reliably transmitted between stationary and rotating parts of the excavator, enabling the seamless operation of additional attachments and auxiliary devices. This feature expands the range of potential applications for excavators and allows for greater adaptability on construction sites.Moreover, the excavator rotary union developed by {Company Name} has undergone extensive testing and quality assurance measures to ensure compliance with industry standards. By meeting stringent performance criteria, the product provides peace of mind to construction companies, knowing they can rely on the equipment to perform optimally in any working conditions.With advancements in technology, the latest excavator rotary unions feature compact designs that fit seamlessly into modern hydraulic systems. {Company Name}'s product, for instance, has a streamlined structure that minimises weight and space requirements. This not only enhances the overall efficiency of the excavator but also provides additional room for other essential components.In conclusion, the excavator rotary union has progressed significantly in recent years, and {Company Name} has been at the forefront of this evolution. Their commitment to innovation and superior performance has resulted in a product that meets the demanding requirements of the construction industry. By ensuring reliable fluid and electrical transmission, remarkable durability, and compliance with industry standards, {Company Name} has positioned itself as a reliable partner in the quest for greater efficiency, productivity, and versatility in the field of excavators.