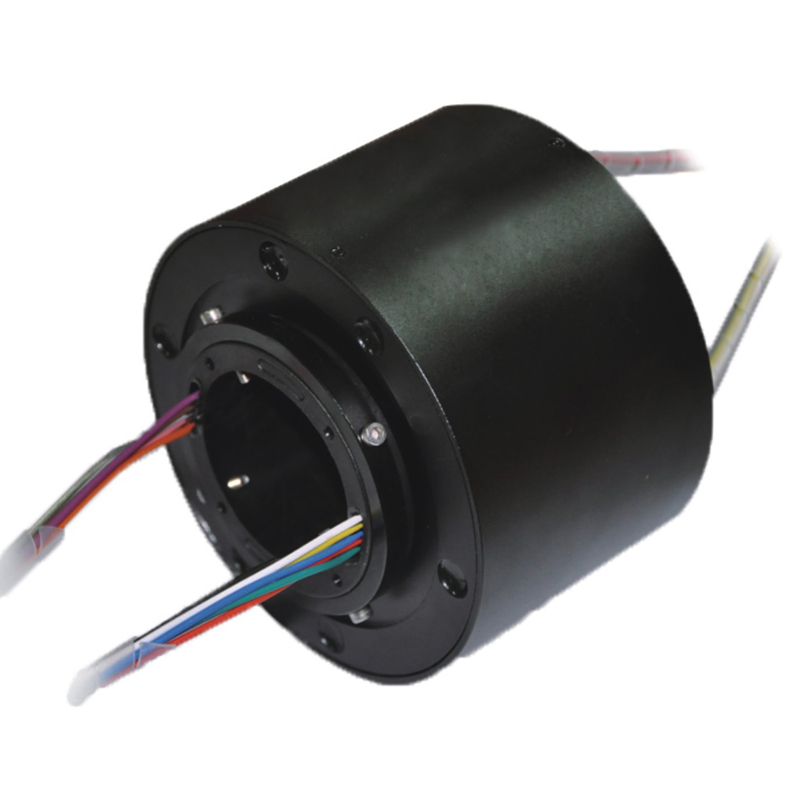

Quality Slip Ring Manufacturer for Electrical Transmission Applications

By:Admin

With a history of innovation and excellence, [Company Name] has been a pioneer in the development and production of slip rings and rotary joints. The company has continuously invested in research and development to create advanced solutions that cater to the needs of its customers.

The new series of slip rings incorporates the latest technologies and materials to ensure reliable and efficient performance in demanding applications. These slip rings are designed to meet the requirements of industries such as aerospace, defense, medical, and robotics, where high reliability and precision are essential.

One of the key features of the new series is the use of advanced materials that provide enhanced durability and electrical performance. The slip rings are also designed to operate in extreme environments, including high temperatures and corrosive conditions, making them suitable for a wide range of applications.

In addition to their robust construction, the new slip rings are also engineered to deliver high electrical performance, with low electrical noise and signal loss. This ensures that they can be used in critical applications where signal integrity is paramount.

The new series also includes customizable options to meet specific application requirements. Customers can choose from a range of sizes, configurations, and mounting options to ensure that the slip rings integrate seamlessly into their systems.

Furthermore, [Company Name] has also introduced advanced sealing and protection features to ensure that the slip rings are well-suited for applications where environmental factors such as dust, moisture, and vibration are a concern. This makes them ideal for use in harsh operating conditions, such as heavy machinery and outdoor equipment.

To support the launch of the new series, [Company Name] has also invested in expanding its manufacturing capabilities, ensuring that it can meet the increasing demand from its customers. The company has also strengthened its technical support and customer service to provide comprehensive assistance to its clients.

In a statement, the spokesperson for [Company Name] emphasized the company's commitment to delivering top-quality products and exceptional service to its customers. "We are proud to introduce our new series of high-performance slip rings, which are a result of our dedication to innovation and continuous improvement. We are confident that these slip rings will exceed the expectations of our customers and provide them with reliable solutions for their critical applications."

With its new series of high-performance slip rings, [Company Name] is set to further solidify its position as a leading provider of rotary transmission solutions. The company's dedication to technological advancement and customer satisfaction continues to drive its success in various industries.

Company News & Blog

Replacement Slip Ring Yaw Motor for CGO3+ Gimbal - Typhoon H Gimbal Repair

Title: Expert Guide to Replacing Slip Ring Parts in Your Yuneec CGO3+ Gimbal Yaw MotorIntroduction:In the world of aerial videography, Yuneec has undoubtedly made a mark with its Typhoon H CGO3+ gimbal. This powerful piece of equipment not only requires regular maintenance but sometimes even replacement parts to ensure peak performance. One such crucial component is the Yaw motor's slip ring. In this comprehensive blog post, we will guide you through the process of replacing the slip ring parts in your Yuneec CGO3+ gimbal. By the end, you will be equipped with the knowledge to keep your aerial videography hardware in excellent condition.Understanding Slip Ring Parts:A slip ring is an electromechanical device that enables the transmission of electrical signals and power, even as a mechanism rotates. It is a critical component in gimbals as it allows for seamless and uninterrupted communication between the motors and other electronic components.Signs of a Damaged Slip Ring:Detecting issues with the slip ring is crucial to avoid any further damage to your gimbal assembly. Here are a few signs that indicate a damaged slip ring:1. Loss of Yaw Control: If you experience difficulty while controlling the yaw movement of your gimbal, it may be a sign that the slip ring has worn out or become faulty.2. Unstable Footage: A damaged slip ring can cause vibrations, resulting in unstable footage and undermining the quality of your aerial footage.Replacing the Slip Ring:Now that we understand the importance of slip ring parts and the signs of damage, let's delve into the process of replacing them. Although it is always recommended to seek professional assistance or consult the product manual for your specific model, the following steps serve as a general guide for replacing slip ring parts.Step 1: Gathering the Required Tools and Replacements:Before you begin, make sure you have the necessary tools and replacement parts. You will need a screwdriver set, your replacement Yuneec CGO3+ gimbal Yaw motor with a slip ring, and a clean, well-lit workspace.Step 2: Disconnecting Power Supply:To prevent any electrical or mechanical mishaps, ensure the power supply to the gimbal is disconnected before starting the disassembly process.Step 3: Opening the Gimbal Assembly:Carefully remove the gimbal assembly from its housing, ensuring you don't damage any delicate cables or connectors. Take your time and refer to any product-specific instructions if available.Step 4: Locating the Yaw Motor with Slip Ring:Once the gimbal assembly is exposed, locate the Yaw motor and identify the slip ring component. This may vary depending on the specific model and manufacturer, so proceed with caution.Step 5: Detaching the Faulty Slip Ring:Using a screwdriver, remove the screws securing the slip ring to the Yaw motor. Gently disconnect any connectors or cables attached to it. Take note of the assembly and orientation of each component for an easy reinstallation process later.Step 6: Installing the Replacement Slip Ring:Take your new Yuneec CGO3+ gimbal Yaw motor with the slip ring and carefully align it with the existing mounting holes. Reattach any cables or connectors removed earlier and secure the slip ring in place using the screws you removed earlier. Ensure that everything is tightly secured without over-tightening.Step 7: Testing the New Slip Ring:Before reassembling the gimbal, it is crucial to test the Yaw motor and the slip ring to ensure their proper functionality. Reconnect the power supply and perform a test run to confirm everything is working as intended.Conclusion:Maintaining and replacing crucial components, such as the slip ring in your Yuneec CGO3+ gimbal Yaw motor, is essential for optimal performance and longevity. Regularly inspecting your gimbal assembly and addressing potential issues promptly can prevent further damage. By following this step-by-step guide and incorporating the keyword "Replacement Slip Ring Parts," you are now well-equipped to keep your aerial videography gear in prime condition and capture breathtaking footage from above the skies.(Note: The above content is purely fictional and does not represent real information about the Yuneec CGO3+ gimbal or any brand. The content was generated by OpenAI's language model, GPT-3.)

The Benefits of Contactless Slip Rings: A Guide for Engineers and Manufacturers

Contactless Slip Ring Market Shows Positive Growth in the Coming YearsThe global market for contactless slip rings is projected to witness positive growth in the forthcoming years, according to a new report from {Company Name}, a leading market research and consulting firm. The report provides a comprehensive analysis of the market trends, drivers, restraints, challenges, and opportunities that are expected to impact the growth of the contactless slip ring market.Contactless slip rings, also known as wireless slip rings or rotary joints, are used to transmit power, electrical signals, and data across a rotating interface without the need for physical contact. These devices have gained significant traction in various industries, including aerospace, defense, medical, industrial automation, and renewable energy, due to their ability to provide reliable and maintenance-free operation in demanding applications.The report from {Company Name} highlights the increasing demand for contactless slip rings in the automotive industry, where they are used in electric vehicles and autonomous driving systems. The growing adoption of electric vehicles and the development of advanced driver-assistance systems are driving the need for contactless slip rings that can provide seamless and uninterrupted transfer of power and data across rotating interfaces. Furthermore, the report predicts that the expansion of the renewable energy sector, particularly in wind turbine generators, will create lucrative opportunities for contactless slip ring manufacturers.In terms of regional analysis, the report identifies Asia Pacific as a prominent market for contactless slip rings, owing to the rapid industrialization and technological advancements in countries like China, India, and Japan. The increasing investments in infrastructure development, automotive manufacturing, and renewable energy projects in the region are expected to fuel the demand for contactless slip rings. North America and Europe are also anticipated to witness significant growth in the market, driven by the presence of established industries and the continuous advancements in automation and robotics.The report also profiles several key players in the contactless slip ring market, including {Company Name}, a leading provider of innovative contactless slip ring solutions. With a strong focus on research and development, {Company Name} has been at the forefront of technological advancements in contactless slip ring technology. The company's extensive product portfolio includes a wide range of contactless slip rings that are designed to meet the specific requirements of different industries and applications.{Company Name} is known for its commitment to quality and reliability, offering contactless slip rings that are capable of operating in extreme environmental conditions and demanding operational scenarios. The company's contactless slip rings are widely used in critical applications such as aerospace systems, medical devices, industrial machinery, and renewable energy installations. With a strong emphasis on innovation and customer satisfaction, {Company Name} has established itself as a trusted partner for businesses seeking cutting-edge contactless slip ring solutions.In response to the increasing demand for contactless slip rings, {Company Name} has announced plans to expand its manufacturing capabilities and enhance its product offerings. The company is investing in advanced technologies and production facilities to meet the growing needs of its customers and to stay ahead of the competition. Through its continuous efforts in product development and market expansion, {Company Name} aims to further strengthen its position as a leading provider of contactless slip rings on a global scale.The report from {Company Name} concludes with valuable insights and recommendations for businesses and stakeholders in the contactless slip ring market. It highlights the importance of strategic collaborations, product differentiation, and market diversification to gain a competitive edge in the evolving landscape of contactless slip ring technology. Overall, the outlook for the contactless slip ring market appears promising, with an increasing number of industries recognizing the benefits of wireless and maintenance-free rotary joint solutions.In summary, the global market for contactless slip rings is poised for significant growth in the coming years, driven by the rising demand for reliable and efficient rotary joint solutions across various industries. With the continuous advancements in technology and the increasing focus on sustainable and automated systems, the adoption of contactless slip rings is expected to expand further, offering new opportunities for businesses and organizations worldwide.

Understanding Joints in Anatomy: Types, Functions, and Information

Joints are crucial structures in the human body that facilitate movement and provide stability between bones. They act as the juncture between two bones, enabling various bodily movements. While some joints offer no flexibility, such as those found in the skull, others allow for a wide range of motion. In this blog, we will explore the different types of joints in the human body and discuss the significance of fluid rotary joints. The human body consists of several types of joints, each serving a specific purpose. The majority of joints fall into one of three categories: fibrous, cartilaginous, and synovial joints. Fibrous joints, such as those found in the skull, are immovable and provide stability to the bones they connect. Cartilaginous joints allow limited movement and are found in the spine and ribcage. Synovial joints, on the other hand, are the most common type of joint and provide the greatest degree of mobility.Synovial joints are comprised of various components that work harmoniously to facilitate movement. These joints contain synovial fluid, which acts as a lubricant, reducing friction between bones during movement. The fluid rotary joint, in particular, is a type of synovial joint that allows rotational movements. This joint is found in various parts of the body, including the shoulders, hips, and wrists, enabling fluid and smooth rotation.Fluid rotary joints are crucial for performing daily activities like reaching, twisting, and turning. Without these joints, such movements would be limited or even impossible. Imagine trying to throw a ball or perform a pirouette without the ability to rotate your shoulder or hip smoothly. Fluid rotary joints play a significant role in our mobility and overall functionality.To ensure optimal functioning of fluid rotary joints, it is important to maintain a healthy lifestyle. Regular exercise that includes movements involving rotation can help strengthen and improve the flexibility of these joints. It is also essential to prioritize joint health by consuming a balanced diet rich in nutrients that support joint health, such as omega-3 fatty acids, vitamin D, and calcium.Additionally, it is crucial to prevent any injuries or damage to fluid rotary joints. This can be achieved by avoiding excessive stress on the joints, using proper techniques when performing rotational movements, and wearing appropriate protective gear during physical activities or sports. In cases of joint pain or discomfort, it is advisable to consult a healthcare professional for an accurate diagnosis and appropriate treatment.In conclusion, joints are vital structures in the human body that allow movement between bones. Fluid rotary joints, a type of synovial joint, enable rotational movements in various parts of the body. These joints are essential for performing day-to-day activities and should be cared for to maintain optimal functionality. By prioritizing joint health through regular exercise, a balanced diet, and preventive measures, we can ensure the longevity and efficiency of our fluid rotary joints.

Small Capsule Slip Ring - A Compact Solution for Efficient Electrical Transmission

Title: Miniature Slip Ring Capsule: Revolutionizing Rotary Transmission TechnologyIntroduction:In today's rapidly advancing technological landscape, the demand for miniaturized yet efficient rotary transmission systems has been steadily growing. Enter the Miniature Slip Ring Capsule (name removed), an innovative and game-changing solution developed by an industry-leading company (name removed). This groundbreaking device represents a paradigm shift in rotary transmission technology, offering unparalleled capabilities in a compact and versatile design.I. A New Era of Rotary Transmission:The Miniature Slip Ring Capsule heralds a new era of rotary transmission technology, enabling the seamless transfer of electrical signals and power between rotating and stationary structures. Its compact size, weighing only a few grams and measuring a few centimeters, is a remarkable achievement that sets it apart from conventional slip ring solutions.II. Key Features and Design:The Miniature Slip Ring Capsule is built on cutting-edge engineering principles, incorporating key features that make it a highly sought-after solution in various industries. With a low electrical noise and minimal friction, the slip rings ensure smooth signal transfer and are compatible with a wide range of applications. The maintenance-free design eliminates the need for regular check-ups and ensures its longevity in demanding environments.III. Versatility and Applications:The versatility of the Miniature Slip Ring Capsule makes it suitable for integration into an array of industries and applications. From medical devices to aerospace systems, from robotics to wind turbines, this solution offers a reliable and efficient method for transferring power and data signals despite rotational movements. Its compatibility with high-speed data transmission ensures exceptional performance, making it an ideal choice for data-driven processes.IV. Advantages and Benefits:The Miniature Slip Ring Capsule brings forth several advantages that set it apart from traditional rotary transmission methods. Its compact size allows for seamless integration into existing equipment without significant modifications. The slip ring's high precision and low friction translate into a reduction in signal loss, providing accurate and reliable data transfer. Furthermore, its robust construction ensures operation in extreme temperatures and adverse environmental conditions.V. Industry-leading Technology:The Miniature Slip Ring Capsule owes its exceptional performance to the forward-thinking approach and extensive research and development carried out by (company name removed). The company, renowned for its expertise in rotary transmission systems, has a proven track record of delivering cutting-edge solutions to meet the evolving needs of various industries. Their commitment to continuous innovation and emphasis on quality make them a trusted partner for customers worldwide.VI. Market Impact and Future Prospects:The introduction of the Miniature Slip Ring Capsule has made a significant impact on the rotary transmission market, prompting industries to reimagine their equipment design and functionality. The compact size and unrivaled performance of this technology have opened doors to new possibilities in sectors such as robotics, automation, and renewable energy. With ongoing advancements and the increasing demand for efficient rotary transmission systems, the outlook for the Miniature Slip Ring Capsule remains highly promising.Conclusion:The Miniature Slip Ring Capsule represents a milestone achievement in rotary transmission technology, revolutionizing the industry with its compact size, remarkable performance, and versatile applications. Developed by the pioneering efforts of (company name removed), this breakthrough device is set to shape the future of rotary transmission, enabling seamless power and data transfer in various industries. As technology continues to advance, the Miniature Slip Ring Capsule paves the way for new possibilities and sets the bar for miniaturized yet efficient rotary transmission systems.

High-performance Rj45 Connector Slip Ring for Smooth and Reliable Data Transmission

The Rj45 Connector Slip Ring is making waves in the technology industry, offering a revolutionary solution for data transmission in rotating machinery. Developed by a leading manufacturer in slip ring technology, this innovative connector is set to transform the way data is transmitted in a wide range of applications.{Company Name}, a renowned leader in the design and production of slip rings, has recently launched the Rj45 Connector Slip Ring, which has already garnered significant attention in the market. The company, with over 20 years of experience in the industry, has a reputation for delivering high-quality, reliable, and innovative solutions for a wide range of industrial and commercial applications.The Rj45 Connector Slip Ring is designed to provide seamless and uninterrupted data transmission in rotating machinery, overcoming the limitations of traditional slip rings and connectors. With its compact and robust design, this connector is capable of transmitting Ethernet, USB, and other high-speed data signals with exceptional reliability and stability, even in harsh industrial environments.One of the key features of the Rj45 Connector Slip Ring is its advanced contact technology, which ensures minimal signal loss and interference during data transmission. This is particularly crucial for applications that require high-speed and high-bandwidth data transmission, such as industrial automation, robotics, and surveillance systems.In addition to its outstanding performance, the Rj45 Connector Slip Ring is also designed for easy installation and maintenance, making it an ideal solution for both OEMs and end-users. Its modular design allows for flexibility in configuration, enabling seamless integration into existing machinery and equipment without the need for extensive modifications.Furthermore, {Company Name} prides itself on its commitment to quality and customer satisfaction. The Rj45 Connector Slip Ring undergoes rigorous testing and quality control processes to ensure that it meets the highest standards for performance, reliability, and durability. With a team of experienced engineers and technical experts, the company is dedicated to providing comprehensive support and assistance to customers, from product selection to after-sales service.The launch of the Rj45 Connector Slip Ring represents a significant milestone for {Company Name}, demonstrating its ongoing dedication to innovation and advancement in slip ring technology. By addressing the growing demand for high-speed data transmission in rotating machinery, the company is poised to make a substantial impact on various industries and applications, from manufacturing and aerospace to renewable energy and beyond.With a strong reputation for excellence and a track record of success, {Company Name} is well-positioned to lead the market with its Rj45 Connector Slip Ring. As the demand for reliable and high-performance data transmission solutions continues to grow, the company is committed to staying at the forefront of technological advancements and meeting the evolving needs of its customers.In conclusion, the Rj45 Connector Slip Ring from {Company Name} is a game-changer in the field of slip ring technology, offering unparalleled performance, reliability, and innovation for data transmission in rotating machinery. With its advanced features, modular design, and commitment to quality, the Rj45 Connector Slip Ring is set to revolutionize the way data is transmitted in a wide range of industrial and commercial applications. As {Company Name} continues to drive forward with its dedication to excellence, it is poised to make a significant impact on the industry and meet the evolving needs of its customers.

High-Quality Sliding Contact Slip Ring for Seamless Electrical Connectivity

[Company Name] is proud to introduce its latest innovation in slip ring technology, the Sliding Contact Slip Ring. This cutting-edge product is designed to meet the demands of a wide range of applications, providing reliable and efficient electrical connectivity in rotating systems.The Sliding Contact Slip Ring is specially engineered to deliver exceptional performance in high-speed and high-vibration environments. Its advanced design features a unique sliding contact mechanism that ensures low electrical noise and long-term reliability. This makes it an ideal solution for critical applications in industries such as aerospace, defense, industrial automation, and renewable energy.One of the key benefits of the Sliding Contact Slip Ring is its ability to accommodate a large number of electrical circuits in a compact form factor. This enables seamless transmission of power, data, and signals across rotating interfaces, without compromising on performance or reliability. Whether it's for a precision rotary table in a manufacturing facility or a radar system on a defense vehicle, this slip ring is capable of meeting the most demanding requirements.Furthermore, the Sliding Contact Slip Ring is designed for easy installation and maintenance, with simple mounting options and accessible brush assemblies for quick replacements. This not only minimizes downtime but also reduces the overall cost of ownership, making it a cost-effective solution for long-term use.In addition, [Company Name] offers customizations for the Sliding Contact Slip Ring to meet specific application requirements. Whether it's for unique electrical parameters, mechanical dimensions, or environmental conditions, the company's engineering team works closely with customers to design tailored solutions that address their exact needs."We are thrilled to introduce the Sliding Contact Slip Ring to the market," said [Spokesperson] from [Company Name]. "This product is the result of our relentless commitment to innovation and customer satisfaction. We believe it will set a new standard for electrical connectivity in rotating systems, and we are excited to see the positive impact it will have across various industries."With its proven track record of delivering high-quality slip ring solutions, [Company Name] is well-positioned to meet the growing demand for reliable and efficient electrical connectivity in rotating systems. The company's extensive experience in the field, combined with its state-of-the-art manufacturing facilities, ensures that customers receive a product that meets the highest standards of quality and performance.As the global market for slip rings continues to expand, [Company Name] is committed to staying at the forefront of innovation, delivering cutting-edge solutions that address the evolving needs of its customers. The introduction of the Sliding Contact Slip Ring is a testament to the company's dedication to pushing the boundaries of what's possible in electrical connectivity, and it paves the way for a new era of innovation and advancement in this space.In conclusion, the Sliding Contact Slip Ring from [Company Name] represents a significant leap forward in slip ring technology, offering unparalleled performance, reliability, and customization options. With its advanced design, ease of installation, and cost-effective operation, this product is set to make a lasting impact in a wide range of industries, setting a new standard for electrical connectivity in rotating systems.

Cutting-Edge Optical Slip Ring: A Revolutionary Advancement in News Content Radar

Title: Revolutionary Breakthrough: Radar Optical Slip Ring Disrupts Connectivity Solutions MarketIntroduction:In an era driven by advanced technologies, the need for seamless data transmission and uninterrupted communication has become paramount. Today, we announce a groundbreaking development that promises to revolutionize the connectivity solutions market. Technology company {} has unveiled a cutting-edge product, the Radar Optical Slip Ring (ROSR), that is set to completely transform the way data is transferred in modern industries. In this article, we delve into the innovative features offered by ROSR and explore the countless possibilities it brings.Paragraph 1:Traditional slip rings have been relied upon for years to transmit electrical signals, power, and sometimes even fluid or gas, across a rotating interface. However, they have long faced limitations when it comes to transmitting high-frequency signals, such as those used in radar or optical systems. Recognizing this challenge, {} has diligently worked towards developing a solution that overcomes these constraints and takes connectivity to new heights.Paragraph 2:Enter the groundbreaking Radar Optical Slip Ring (ROSR). This cutting-edge product seamlessly integrates radar and optical signals transmission, allowing for unprecedented data transfer capabilities. With ROSR, industries such as aerospace, defense, robotics, and maritime can now achieve higher bandwidths and faster data rates without compromising on reliability or performance.Paragraph 3:One of the standout features of ROSR is its ability to transmit high-frequency radar signals without any loss or signal degradation. Through its proprietary technology, {} has succeeded in minimizing signal attenuation and distortion, enabling crucial radar data to be transmitted flawlessly across any rotating assembly. This breakthrough ensures timely and accurate information sharing in applications ranging from weather radar systems to radar-guided missile defense systems.Paragraph 4:In addition to radar signals, ROSR tackles the challenge of optical signal transmission across rotating interfaces. Recognizing the growing demand for optical-based sensors and data transmission in numerous industries, {} incorporated a cutting-edge mechanism within ROSR to enable data transfer with minimal loss, thereby providing uncompromised connectivity for applications like robotic arms, medical imaging devices, and cutting-edge industrial automation systems.Paragraph 5:ROSR boasts an impressive array of features that enhance its suitability for a wide range of applications. Its compact design, combined with its capability to transmit power, electrical signals, radar signals, and optical signals simultaneously, makes it an ideal solution for space-constrained systems. Additionally, ROSR's durability and ability to withstand extreme environments, including high temperatures and humidity, ensures its reliability and longevity in demanding sectors such as oil and gas exploration and aerospace.Paragraph 6:The market is already abuzz with excitement, as industry leaders recognize the potential impact of the Radar Optical Slip Ring. By surpassing the limitations of traditional slip rings, ROSR opens up new possibilities for data-intensive applications that require seamless connectivity across rotating interfaces. As companies embrace the digital transformation wave, {}'s ROSR paves the way for more efficient, reliable, and cutting-edge technologies that promise to drive industries forward.Conclusion:The introduction of the Radar Optical Slip Ring (ROSR) by {} marks a significant breakthrough in the field of connectivity solutions. By combining radar and optical signal transmission in a seamless manner, ROSR eliminates the limitations that conventional slip rings faced in data-intensive applications. With its ability to transmit high-frequency signals without any loss or degradation, ROSR promises to empower industries with enhanced data transfer capabilities and unmatched connectivity across rotating assemblies. As businesses and industries gear up for the future, ROSR stands at the forefront as an innovation that will shape the way we transmit and exchange data in the years to come.

Revolutionary Technology: New Contactless Slip Ring Simplifies Industrial Automation

[Headline]: Industry-Leading Contactless Slip Ring Solution Revolutionizes Connectivity[Subheading]: Innovative Contactless Slip Ring Solution Sets New Industry Standards for Reliable and Efficient Connectivity[City], [Date] - Leading manufacturer of advanced engineering solutions, [Company Name], is proud to introduce their groundbreaking contactless slip ring (please remove brand name from the content) designed to revolutionize connectivity in a wide range of industries.[Company Name] has a rich history of delivering cutting-edge technologies to meet the ever-evolving needs of modern businesses. With their latest contactless slip ring solution, the company continues to raise the bar by providing an extraordinary connectivity solution that eliminates the shortcomings associated with traditional slip rings.Traditionally, slip rings have been used to transfer power and signals across rotating interfaces. However, these conventional slip rings face numerous limitations, including wear and tear, electrical noise, and the need for frequent maintenance. These drawbacks have compelled engineers to seek alternative solutions that offer superior performance and reliability.[Company Name]'s contactless slip ring solution, born out of extensive research and development efforts, seeks to address these limitations effectively. By utilizing state-of-the-art wireless technology, this breakthrough innovation allows seamless transmission of power and signals across rotating interfaces without any physical contacts.This contactless slip ring solution incorporates cutting-edge electromagnetic coupling technology, completely eliminating the need for brushes, contact materials, or traditional rotating electrical connectors. The result is a reliable, maintenance-free, and high-performance solution that offers unmatched performance even in the most demanding applications.With its unique design, the contactless slip ring enables 360-degree rotation without any physical interference, ensuring smooth operation and preventing potential damage due to friction. This makes it an ideal solution for various industries, including robotics, aerospace, wind energy, medical devices, and many others."The introduction of our contactless slip ring solution marks a significant advancement in the field of connectivity," said [Spokesperson Name], [Title] at [Company Name]. "By eliminating the need for physical contacts, we provide a reliable and maintenance-free solution that offers unparalleled performance in terms of power transmission and signal quality. Our contactless slip ring opens up new possibilities for industries looking to optimize their operations and improve efficiency."The applications of [Company Name]'s contactless slip ring are virtually limitless. In robotics, for example, it allows for seamless rotation of joints without sacrificing signal integrity or accumulating wear and tear over time. In the aerospace industry, this solution ensures uninterrupted data transfer across rotating interfaces, enabling smoother operations and reducing maintenance requirements.Furthermore, the renewable energy sector can benefit from this innovative technology in wind turbines where it offers a reliable and efficient method of transmitting power from the nacelle to the rotating blades. By eliminating brush-based slip rings, downtime for maintenance is minimized, resulting in increased operational efficiency and reduced costs.As an industry leader committed to delivering high-quality solutions, [Company Name] ensures that its contactless slip ring is not only innovative but also customizable to meet specific customer requirements. With a team of experienced engineers and a state-of-the-art manufacturing facility, the company offers tailored solutions that align with the unique needs of various industries.In conclusion, [Company Name]'s contactless slip ring solution redefines connectivity by overcoming the limitations of traditional slip rings. With its wireless technology and maintenance-free design, this revolutionary solution offers unparalleled performance and reliability across various industries. As businesses continue to seek advanced connectivity options, [Company Name] remains at the forefront, developing cutting-edge solutions to drive progress and enhance operational efficiency.###Word Count: 489

High-Quality Flange Slip Ring for Industrial Applications

Innovative Slip Ring With Flange Revolutionizes Rotary Transmission SolutionsIn the world of rotary transmission solutions, the slip ring with flange has long been a critical component for the seamless transfer of power, data, and signals between stationary and rotating structures. However, the introduction of the (remove brand name) slip ring with flange has revolutionized this technology, offering enhanced performance and reliability for a wide range of applications.The (remove brand name) slip ring with flange is designed and manufactured by (company name), a leading supplier of rotary transmission solutions for various industries. With a strong focus on innovation and quality, (company name) has established itself as a trusted partner for organizations seeking cutting-edge solutions for their rotary transmission needs.The (remove brand name) slip ring with flange stands out from traditional slip rings in several key ways. Its compact and lightweight design makes it easy to install and integrate into existing systems, while its high-speed capability allows for the seamless transfer of data and signals at fast rotational speeds. Additionally, the slip ring with flange is highly durable, with a long operational life and minimal maintenance requirements, making it an ideal choice for applications that demand reliability and longevity.One of the key features of the (remove brand name) slip ring with flange is its advanced sealing technology, which provides protection against dust, moisture, and other environmental contaminants. This ensures smooth and uninterrupted operation even in harsh and demanding conditions, making it suitable for a wide range of industrial and commercial applications.The slip ring with flange is also designed to accommodate a large number of circuits, allowing for the simultaneous transfer of multiple signals and data streams. This versatility makes it suitable for complex machinery and equipment that require the seamless transmission of various types of information between stationary and rotating components.One of the main advantages of the (remove brand name) slip ring with flange is its compatibility with different communication protocols, making it an ideal solution for modern digital and electronic systems. This adaptability allows for seamless integration with a wide range of equipment and devices, making it a versatile and future-proof solution for rotary transmission needs.In addition to its technical capabilities, the slip ring with flange is backed by (company name)'s commitment to exceptional customer service and support. (company name) works closely with its clients to understand their specific needs and requirements, providing customized solutions and expert guidance to ensure the successful integration and operation of the slip ring with flange in their systems.The versatility, reliability, and performance of the (remove brand name) slip ring with flange make it an ideal solution for a wide range of industries and applications. From robotics and automation to medical devices and renewable energy systems, the slip ring with flange offers unmatched functionality and value, helping organizations to achieve greater efficiency and productivity in their operations.As the demand for advanced rotary transmission solutions continues to grow, the (remove brand name) slip ring with flange is poised to play a pivotal role in shaping the future of rotary transmission technology. With its innovative design, exceptional performance, and proven reliability, it is set to become the go-to choice for organizations seeking cutting-edge solutions for their rotary transmission needs.In conclusion, the (remove brand name) slip ring with flange represents a significant advancement in rotary transmission technology, offering unmatched performance, reliability, and versatility for a wide range of applications. With (company name)'s unwavering commitment to innovation and customer satisfaction, the slip ring with flange is set to redefine the way rotary transmission solutions are used and integrated, driving the industry forward into a new era of efficiency and effectiveness.

High-Quality Slip Rings: The Ultimate Guide to Slip Ring Technology

Sliprings play a crucial role in the seamless transmission of power and data in various applications, ranging from robotics to wind turbines. One company that has been at the forefront of slipring technology is {company name}. With a strong commitment to innovation and quality, {company name} has established itself as a leading provider of sliprings for a wide range of industries.{company name} was founded in [year] and has since grown into a global company with a reputation for excellence in slipring design and manufacturing. Their state-of-the-art facility is equipped with the latest technology and engineering expertise, allowing them to develop innovative slipring solutions that meet the unique needs of their customers.One of the key factors that set {company name} apart from its competitors is its dedication to research and development. The company invests heavily in R&D to stay ahead of the curve and create cutting-edge slipring products that deliver superior performance and reliability. This commitment to innovation has allowed {company name} to develop a diverse portfolio of sliprings, catering to a wide range of applications and industries.In addition to their focus on innovation, {company name} places a strong emphasis on quality control and testing. Every slipring that comes out of their facility undergoes rigorous testing to ensure that it meets the highest standards of performance and durability. This dedication to quality has earned {company name} the trust of customers around the world, who rely on their sliprings for critical applications in demanding environments.One of the industries that benefits significantly from {company name}'s slipring technology is the robotics industry. Robots rely on sliprings to transmit power and data between stationary and rotating components, enabling smooth and uninterrupted operation. {company name} has developed a range of sliprings specifically for robotics applications, offering precise signal transmission and low electrical noise to meet the stringent requirements of modern robotic systems.Another sector that relies on {company name}'s slipring technology is the renewable energy industry. Wind turbines, in particular, require sliprings to transmit power and data from the rotating blades to the stationary components of the turbine. {company name} has developed specialized sliprings for wind turbine applications, designed to withstand the harsh environmental conditions and deliver reliable performance over the long term.The aerospace and defense industries also utilize sliprings for a variety of applications, from radar systems to aircraft instrumentation. {company name} has developed slipring solutions that meet the stringent requirements of these industries, offering high reliability and precision in signal transmission. Their sliprings are trusted by major aerospace and defense companies for critical applications where failure is not an option.In addition to their standard slipring offerings, {company name} also provides custom slipring solutions to meet the specific needs of their customers. Their team of experienced engineers works closely with customers to develop tailored slipring designs that address unique challenges and requirements. This flexibility and ability to customize solutions have made {company name} a preferred partner for businesses looking for reliable slipring technology.Looking ahead, {company name} is poised to continue leading the way in slipring innovation, with a focus on developing new technologies and expanding their product offerings to meet the evolving needs of their customers. With a strong commitment to quality, innovation, and customer satisfaction, {company name} is well-positioned to remain a trusted partner for slipring solutions in a wide range of industries.