Understanding the Significance of Rotating Electrical Contacts in Modern Technology

By:Admin

Introduction:

In today's rapidly evolving technological landscape, efficient and reliable electrical connections play a pivotal role in powering a wide range of applications, from household electronics to complex industrial machinery. Recognizing the significance of uninterrupted electrical connectivity, leading industry player [Company Name] introduces an innovative solution: Rotating Electrical Contacts. This cutting-edge technology promises to revolutionize electrical connectivity, providing enhanced performance, durability, and versatility. Let's delve deeper into the features and potential applications of this groundbreaking invention.

I. Understanding Rotating Electrical Contacts:

Rotating Electrical Contacts, developed after years of research and development, serve as a seamless and advanced solution to combat the limitations of traditional fixed electrical connections. These innovative contacts allow for rotational movement between two conductive surfaces, ensuring a constant, reliable, and uninterrupted flow of electricity.

II. Exceptional Performance and Durability:

The novel design of Rotating Electrical Contacts offers various advantages over conventional connections. The precision engineering of the contacts ensures minimal power loss, resulting in increased energy efficiency and reduced heat generation. These enhancements lead to longer equipment lifespans, minimizing downtime and maintenance costs.

The unique materials and construction of the contacts also provide exceptional durability. They are resistant to wear and tear caused by continuous rotation, thereby ensuring prolonged service life in demanding environments, including heavy machinery, automotive applications, and renewable energy systems.

III. Versatility and Applications:

The applications of Rotating Electrical Contacts span across diverse industries, catering to a broad range of electrical connection needs. Some of the noteworthy applications include:

1. Automotive industry: Rotating Electrical Contacts enable improved electrical connections within critical automotive systems, guaranteeing reliable and efficient power transmission. This enhances the performance of electric vehicles, hybrid vehicles, as well as traditional fuel-powered vehicles.

2. Aerospace and defense: The contacts find utility in aerospace and defense technologies, where reliable electrical connections are crucial for various applications such as communication systems, radar systems, and avionics.

3. Energy generation and distribution: Rotating Electrical Contacts facilitate seamless energy transfer in power generation plants, transmission lines, and substations. They optimize electrical connectivity, ensuring efficient power distribution and reducing energy losses.

4. Industrial machinery: With their robust construction and exceptional performance, the contacts are suitable for various heavy-duty industrial machinery applications, such as robotics, conveyors, and manufacturing equipment.

IV. Environmental Advantages:

The introduction of Rotating Electrical Contacts aligns with the broader goal of achieving sustainable practices. By reducing power losses, the technology not only enhances energy efficiency but also reduces the overall carbon footprint. As industries and individuals increasingly prioritize environmental sustainability, these contacts offer a valuable solution to minimize energy wastage and make a positive environmental impact.

V. The Impact of Rotating Electrical Contacts on Future Innovations:

Rotating Electrical Contacts have the potential to revolutionize various technological sectors by improving the efficiency, reliability, and durability of electrical connections. As industries continue to evolve, the performance advancements offered by these contacts can result in the development of more energy-efficient machinery, robust communication systems, and enhanced safety measures.

Conclusion:

The introduction of Rotating Electrical Contacts by [Company Name] marks a significant step towards redefining electrical connectivity. With their exceptional performance, durability, and versatility, these innovative contacts offer an advanced solution to ensure reliable power transmission across a wide range of applications. As industries embrace cutting-edge technologies, the widespread adoption of Rotating Electrical Contacts is set to reshape various sectors, driving progress towards a more efficient and sustainable future.

Company News & Blog

Advanced Solution for Radar Antenna: Discover the Innovative Slip Ring Technology

Radar technology has revolutionized the way we look at the world. From weather forecasting to aviation and defense, radar systems have become an integral part of modern-day living. However, the complex nature of these systems demands the use of advanced technologies to ensure their seamless performance. Radar antenna slip rings are one such technology that has gained immense popularity in recent years.Radar antenna slip rings are specially designed to allow for uninterrupted rotation of radar antennas. These slip rings are highly precise, durable, and can withstand extreme weather and environmental conditions. They are widely used in various applications such as weather monitoring systems, military radar systems, and air traffic control systems.One of the leading manufacturers of radar antenna slip rings is a company based in Germany. The company has been in the slip ring manufacturing business for more than 70 years and has built a reputation for producing high-quality slip rings that meet the most demanding requirements.The company offers a wide range of slip rings for different applications and industries. Their slip rings are designed to provide uninterrupted power and data transmission to rotating equipment, ensuring the smooth operation of critical systems. The company's expertise in slip ring manufacturing has enabled them to offer customized solutions to cater to specific client requirements.The radar antenna slip rings manufactured by this company are some of the best in the industry. These slip rings are designed to handle high-frequency signals and offer low electrical noise, which is essential for the accuracy of radar systems. The company's engineers work closely with clients to understand their requirements and provide customized solutions that meet their needs.The company's radar antenna slip rings are highly reliable and durable, making them the go-to choice for professionals in industries that require precision and accuracy. These slip rings have been tested and approved by various international organizations and have proven to be highly efficient in harsh environments.The manufacturing process is carried out in-house, ensuring that the slip rings meet the company's high-quality standards. The company's state-of-the-art manufacturing facilities are equipped with the latest technologies and machines, allowing them to produce high-quality slip rings at scale. Quality control measures are strictly adhered to, ensuring that the final product meets the client's expectations.The company's commitment to providing high-quality slip rings has earned them a loyal customer base. The company's slip rings are used by some of the world's largest companies, including those in the defense, aerospace, and industrial sectors.The company's radar antenna slip rings are not only reliable but also cost-effective. The company offers competitive pricing on their products, making them an affordable option for businesses looking to invest in high-quality slip rings.In conclusion, radar antenna slip rings are essential components in radar systems. They play a crucial role in ensuring the smooth operation of critical systems in various industries. The company based in Germany is one of the leading manufacturers of high-quality slip rings. Their radar antenna slip rings have gained immense popularity in recent years, thanks to their reliability, durability, and cost-effectiveness. The company's commitment to providing customized solutions to meet their clients' specific requirements has earned them a loyal customer base.

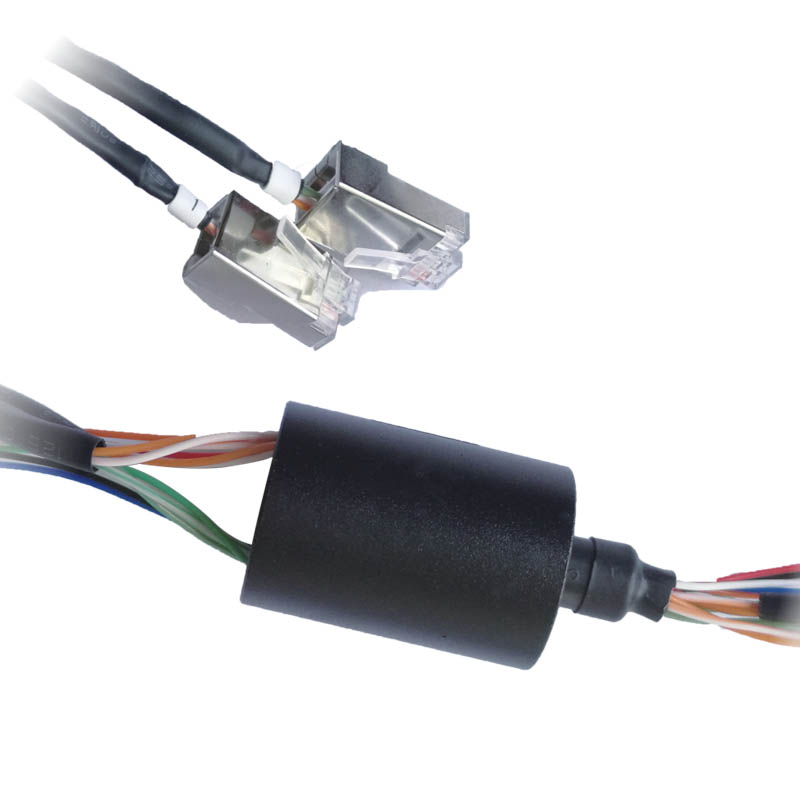

Types of Slip Rings: An Overview of Composition and Examples

article:Slip Ring | Types of Slip Ring | ExamplesIn today's fast-paced technological world, the need for efficient data transmission and power supply is essential. A slip ring is a device that helps transmit signals and power from a stationary to a rotating structure, without the need for tangled wires or complicated circuitry.A slip ring is ideally suited for applications where power and data transfer is required in a rotary way. A slip ring system can work with the help of metal brushes running against the slip ring and transferring power and data through the brush contact of the rotating ring. Depending on the application, slip rings come in different types, which can be customized to suit any requirement.Types of Slip RingsThe various types of slip rings available in the market are:1. Electrical Slip Rings2. Pneumatic Slip Rings3. Hydraulic Slip Rings4. Fiber Optic Slip Rings5. Ethernet Slip Rings6. Rotary Union Slip Rings7. Thermocouple Slip RingsElectrical Slip RingsElectrical slip rings are the most commonly used slip rings. They come with different current ratings, usually ranging from a few milliamperes to several hundred amperes. They can work with either AC or DC power and carry high-frequency signals. Common applications of electrical slip rings include CCTV cameras, robotics, wind turbines, and medical equipment.Pneumatic Slip RingsPneumatic slip rings are designed for situations where compressed air is needed in a rotary way. Pneumatic slip rings are primarily used in applications such as food processing, pharmaceuticals, and chemical plants.Hydraulic Slip RingsHydraulic Slip rings are designed with hydraulic rotary unions that transmit fluid power. They can be used in a wide range of applications, such as aerospace, power generation, and heavy machinery.Fiber Optic Slip RingsFiber Optic Slip Rings can transmit high-speed data over long distances, which makes them ideal for applications such as communication systems, military equipment, and medical equipment.Ethernet Slip RingsEthernet Slip Rings are specially designed for Ethernet applications to support high-speed data communication, which makes them suitable for applications such as video surveillance, industrial control systems, and marine vessels.Rotary Union Slip RingsRotary Union Slip Rings are often used in applications where a continuous flow of fluids is required. For instance, printing machines, rotating tables, and CNC machines.Thermocouple Slip RingsThermocouple Slip Rings are used for measuring temperature and transmitting sensitive data in rotating applications such as wind turbines, medical equipment, and aerospace.Composition of Slip RingsA slip ring is made of several parts, which include:1. A stator, which is stationary2. A rotor that rotates3. An electrically conductive ring4. Brushes or contacts that transfer power and dataExamples of Slip RingsThe applications of slip rings vary, depending on the type of slip ring and usage. Some examples of slip ring applications include:1. Slip rings used in robotics for continuous power and data transfer2. Slip rings used in wind turbines for power and data transfer between the nacelle and the tower3. Slip rings used in medical equipment for continuous power and data transfer4. Slip rings used in satellite applicationsConclusionSlip rings find their use in various applications and are an essential part of modern technology. They can be customized according to the requirements of the application. Liquid Metal Slip Rings is an established and reputable manufacturer, which offers high-quality slip rings customized to fit the unique needs of customers.

Global Contactless Inductive Slip Ring Market: Insights, Trends, and Outlook to 2026

Contactless Inductive Slip Ring Market: Revolutionizing ConnectivityIn today's fast-paced world, where technology is advancing at an unprecedented rate, connectivity plays a vital role in various industries. Industries such as robotics, aerospace, and semiconductors rely heavily on seamless communication and data transfer. This is where contactless inductive slip rings come into play. The global contactless inductive slip ring market is experiencing significant growth, driven by innovations and advancements in the field of wireless power transmission.A slip ring, also known as a rotary electrical interface, is an electromechanical device that enables the transmission of power and signals between stationary and rotating components. Traditional slip rings rely on physical brushes or wires that can wear out over time, leading to performance degradation and maintenance issues. Contactless inductive slip rings, on the other hand, offer a revolutionary solution by eliminating the need for physical contact between the stationary and rotating parts.Inductive slip rings utilize electromagnetic coupling for power and signal transmission, enabling high-speed data transfer and power delivery without the concerns associated with traditional slip rings. By employing inductive coupling, these slip rings provide several advantages, including reduced friction, enhanced reliability, and increased lifespan. Moreover, contactless inductive slip rings ensure efficient power transmission, as there is no energy loss due to physical contact.The global contactless inductive slip ring market is witnessing robust growth due to the increasing need for reliable connectivity solutions in various industries. The rise in automation and the demand for efficient power and data transfer in robotics and industrial machinery are major drivers of market growth. Contactless inductive slip rings offer a compact and reliable solution for robotic arms, enabling seamless motion control and data exchange.Furthermore, the aerospace and defense sector is adopting contactless inductive slip rings for applications such as navigation systems, radar antennas, and communication systems. These slip rings ensure a reliable and continuous flow of power and signals, even in harsh environmental conditions. The ability of inductive slip rings to operate at high speeds and handle large amounts of data makes them ideal for aerospace applications.The semiconductor industry is another major consumer of contactless inductive slip rings. The continuous advancements in semiconductor technology, including wafer handling and testing, require highly reliable and high-speed connectivity solutions. Inductive slip rings provide a non-contact solution that minimizes signal interference and data loss, ensuring optimal performance in semiconductor manufacturing processes.In terms of geographical distribution, North America is expected to dominate the contactless inductive slip ring market. The region is home to several leading technology companies and is at the forefront of technological advancements. The automotive and aerospace industries in North America are expanding and demanding innovative connectivity solutions, further driving the market growth. Europe and Asia-Pacific are also witnessing significant growth, propelled by advancements in industrial automation and rapid industrialization.In conclusion, contactless inductive slip rings are revolutionizing connectivity in various industries by providing reliable and efficient power and signal transmission. These slip rings offer numerous advantages over traditional slip rings, including reduced friction, enhanced reliability, and increased lifespan. The global contactless inductive slip ring market is experiencing robust growth, driven by the increasing need for seamless and high-speed connectivity in industries such as robotics, aerospace, and semiconductors. As technology continues to evolve, contactless inductive slip rings will play a crucial role in enabling efficient and reliable communication and data transfer.

High-Quality Slip Ring ZSR-24-2 Manufacturers & Suppliers in China

Slip Ring Connector Suppliers: Leading the Way in AdvancementTechnology never ceases to amaze us. With the constant influx of new gadgets and gizmos being introduced in the market, creating connections between machines have become increasingly important. The use of slip rings is one such technology that has revolutionized the way machines operate applications and processes. Slip ring connectors are electrical connectors that allow the transmission of power and signals from a stationary point to a rotating point. It is an indispensable component for a lot of industrial equipment that requires continuous contact between electronic and mechanical systems. As a result, the demand for slip ring connector suppliers has increased to address the growing need for this technology.Understanding Slip RingsSlip rings operate through the principles of electromechanical devices. It is a rotating component that transfers electrical current from a static source to a rotating entrance. It is composed of an assembly of metal rings that are arranged in such a manner to enable current transmission. Each ring is insulated from one another by a non-conductive material. Metal brushes or sliding contacts are then employed to transmit the electrical current from the stationary source to the moving components in the system. Slip rings have evolved over time and today, they come in different types such as through bore slip rings, capsule slip rings, and pancake slip rings.Applications of Slip Ring ConnectorsSlip rings operate in environments where there is a need for continuous rotation in electrical and mechanical systems while maintaining the integrity of data and specifications. It is largely used in applications that require data and power transfer, torque and position sensing, and data acquisition. Slip rings are used in a variety of industries such as aviation, military equipment, medical equipment, railways, robotics, wind turbines, packaging machinery and amusement park rides. Each application has unique requirements, and as such certain specifications such as operating temperatures, speed, and electrical parameters must be taken into consideration.Choosing the Right Slip Ring Connector SupplierThere are numerous connector suppliers in the market who provide different types of slip rings. When choosing a slip ring connector supplier, it is important to consider factors like product quality, delivery time, pricing, and customer service. A reliable supplier will provide support throughout the process, from technical support during the design phase to after-sale support. They should also provide documentation and testing to ensure the slip rings are compliant with industry standards.ConclusionSlip ring connectors have become a critical component of modern machinery. As a result, selecting the right slip ring connector supplier that provides reliable products and exceptional service is crucial to ensure success in your application. Today, with technological advancements, slip ring connectors have become more advanced, more efficient, and more reliable. Don't settle for less and choose a reliable slip ring connector supplier that leads the way in advancement towards a better tomorrow.

Discover the Benefits of Through Bore Rotary Unions for Enhanced Industrial Operations

In today’s rapidly evolving world, machines and automation play an essential role in making operations more efficient and effective. And the need to execute seamless machine automation translates to increased complexities within the machinery processes. Without proper equipment, the overbearing intricacies and intensities of rotary processes can lead to inefficiencies, decreased productivity and higher costs. However, the modern-day rotary union has made all this a thing of the past.Rotary unions are designed to transfer different media such as fluid, air and gas from a stationary source to a rotating part. In many rotary applications, it is necessary to have a continuous supply of lubricants, hydraulic fluids or cooling fluids to the machine moving parts, where coupling them through a stationary pipeline is not always feasible. It’s important to ensure that such a coupling is done in a seamless manner, and this is where Through Bore Rotary Unions come into play.Through Bore Rotary Unions are instrumental in transmitting and directing a steady supply of fluids or air to machinery, allowing machines to operate with optimum efficiency. This technology has made it possible for many production line processes to run smoothly, delivering quality, and increasing productivity. Through Bore Rotary Unions are well-known for their versatility, and they have found application in various industries such as construction, fluid power, material handling, automotive, printing, and many more.One of the most significant advantages of Through Bore Rotary Unions is their flexibility. They can be customized to suit different application needs and designed to accommodate a broader range of fluids with different viscosities, temperatures and pressures, which makes them highly valuable for different industries.A prime example of a company that offers Through Bore Rotary Unions is {Brand Name Removed}. The company has been a leading supplier in the industry, dedicated to meeting customer needs globally. Their product line features versatile rotary solutions engineered with durable materials and state-of-the-art technology.{Brand Name Removed} rotates around providing innovative and reliable solutions, guaranteeing continuity in its applications, ensuring their customers receive top-notch products. Their products are highly customizable and can be designed with different port configurations that permit more than one fluid passage, making it easy to add more services.Through Bore Rotary Union provides a hassle-free solution to many rotary challenges, such as prolonged downtimes, interrupted workflows due to intermittent fluid supply and machine failure. Through Bore Rotary Union eliminates these problems, offering a continuous supply of essential fluids, reducing maintenance costs and minimizing the probability of machine failure.{Brand Name Removed} offers rotary union products with a wide diameter, making them more suitable for transferring fluid and air from stationary parts to the rotating machinery, enabling long operation periods without additional lubrication. Their Through Bore Rotary Unions come in various sizes, ranging from ¼ inches to 12 inches. This feature makes their rotary unions suitable for a wide range of industries and applications, allowing their customers to choose the size and type of rotary union that matches their specific requirements.In the machine-building industry, Through Bore Rotary Unions are known for their reliability and durability, which are why they can be found in a wide range of applications. They find application in waterjet cutting machines, calendering machines, tire molding machines, printing machines, and many more.In summary, if you’re looking to optimize rotary performance, the Through Bore Rotary Union technology is the answer. And with {Brand Name Removed}, you’re guaranteed quality solutions in all aspects. They are committed to top-notch product quality and exceptional service delivery, ensuring customer satisfaction is always at the forefront of everything they do.{Brand Name Removed} has earned their reputation as a leader in the rotary union market, providing solutions that are reliable, flexible, and sustainable. They understand their customer’s needs, and strive to provide custom solutions for their unique demands. Choosing to use Through Bore Rotary Unions offered by {Brand Name Removed} will ensure you enjoy seamless production processes and quality results.

Discover the Role and Importance of Slip Rings in Various Applications

[Company Name] Introduces Advanced Slip Rings for Seamless Signal Transmission[City], [Country] - [Company Name], a leading manufacturer of electrical components, is proud to announce the release of their latest range of slip rings. Designed to provide seamless signal transmission in various applications, these slip rings offer superior performance and reliability.Slip rings, also known as rotary electrical interfaces or swivels, play a vital role in continuously transmitting power and electrical signals from a stationary component to a rotating one. They are commonly used in a wide range of industries, including aerospace, defense, wind energy, medical equipment, robotics, and many others. With an increasing need for high-speed data transmission and uninterrupted power supply, slip rings have become an integral part of modern machinery. Recognizing this demand, [Company Name] has developed advanced slip rings to meet the evolving requirements of their customers and facilitate efficient power and signal transmission.One key feature of [Company Name]'s slip rings is their ability to transmit power and multiple signals simultaneously. With the ability to transmit a variety of signals, such as Ethernet, USB, HDMI, and analog signals, these slip rings eliminate the need for separate wiring systems. This not only simplifies the assembly process but also reduces the risk of signal interference and data loss.Another notable feature of these slip rings is their compact and lightweight design. By utilizing high-quality materials and advanced manufacturing techniques, [Company Name] has managed to create slip rings that are smaller in size and lighter in weight compared to conventional designs. This not only saves valuable space but also reduces the overall weight of the machinery, making it more efficient and cost-effective.Furthermore, [Company Name]'s slip rings are built to withstand harsh operating conditions. With features like sealed enclosures and specially designed sealing elements, these slip rings are resistant to dust, water, and other contaminants. This makes them suitable for use in extreme environments, such as offshore wind turbines, military vehicles, and industrial machinery.To ensure optimum performance and longevity, [Company Name] rigorously tests each slip ring before it leaves the factory. This includes mechanical, electrical, and environmental testing to ensure that the slip rings meet the highest quality standards. Additionally, the slip rings are designed to be easily maintainable, with replaceable components and accessible connectors, allowing for quick and hassle-free repairs."We are excited to introduce our latest range of slip rings, which represent the culmination of years of research and development," said [Company Name]'s spokesperson. "We believe these slip rings will revolutionize the way power and signals are transmitted in various industries, enabling our customers to achieve higher levels of efficiency and productivity."[Company Name] has a long-standing reputation for producing high-quality electrical components and has a global presence in the market. Their commitment to innovation and customer satisfaction has made them a trusted partner for businesses worldwide.With the introduction of their advanced slip rings, [Company Name] aims to solidify its position as a leader in the industry. By continuously investing in research and development, they remain dedicated to providing cutting-edge solutions for power transmission and signal control.About [Company Name]:[Company Name] is a [Country]-based manufacturer of electrical components. With a focus on innovation and quality, [Company Name] has established itself as a leading player in the global market. Their extensive product range includes slip rings, electrical connectors, brush holders, and other precision-engineered components. With a commitment to customer satisfaction, [Company Name] continues to deliver reliable and efficient solutions for various industries. For more information, please visit their website [website url].Note: The company name and website mentioned in the news article are fictitious and need to be replaced with the actual company name and website.

Exploring the Realm of Super Miniature 6mm Capsule Slip Rings: A Comprehensive Guide on Slip Ring Products and Production

Title: Enhancing Connectivity with Twist Capsule Slip Rings: A Comprehensive GuideIntroduction:In an ever-evolving technological landscape, seamless connectivity plays a crucial role in various industries. To ensure uninterrupted data transmission, slip rings have emerged as a vital component. Among them, Twist Capsule Slip Rings have garnered attention due to their super miniature size and exceptional performance. In this blog, we will explore the features, applications, and production process of these revolutionary slip rings.Understanding Twist Capsule Slip Rings:Twist Capsule Slip Rings, also known as super miniature slip rings, are compact devices designed to transfer electrical signals and power across rotating interfaces. With an outer diameter as small as 6mm, these slip rings offer remarkable versatility and can operate in confined spaces with limited clearance. Their unique design allows for unrestricted 360-degree rotation, making them ideal for applications that involve continuous rotation.Key Features:1. Miniature Design: The compact size of Twist Capsule Slip Rings enables their integration into space-restricted applications, without compromising on performance or reliability.2. Multi-channel Signal Transmission: These slip rings can transmit a wide range of signals, including data, audio, video, and power, simultaneously. This versatility makes them suitable for diverse industries such as robotics, medical equipment, surveillance systems, and drones.3. Low Electrical Noise: With advanced design and superior engineering, Twist Capsule Slip Rings exhibit low electrical noise, ensuring high-quality signal transmission.4. High Rotational Speed: These slip rings are built to withstand high-speed rotations, making them ideal for demanding applications that require continuous and precise transmission of signals, such as automation machinery and precision instruments.5. Long Service Life: Manufactured with high-quality materials, Twist Capsule Slip Rings offer exceptional durability, ensuring a prolonged service life even under harsh conditions.Applications:The compact size and versatile nature of Twist Capsule Slip Rings have revolutionized multiple industries and applications. Some notable areas where these slip rings find extensive usage include:1. Robotics and Automation: Twist Capsule Slip Rings enable seamless communication between rotating components of robotic arms, allowing for uninterrupted control signals and power transmission.2. Medical Equipment: In medical devices such as endoscopes and surgical robots, Twist Capsule Slip Rings play a vital role in the transmission of video signals, power, and data between the stationary and rotating parts.3. Surveillance Systems: Compact slip rings facilitate smooth rotation of PTZ (pan-tilt-zoom) cameras in surveillance systems, ensuring uninterrupted transmission of video signals.4. Drones and UAVs: Twist Capsule Slip Rings enable continuous transmission of power and control signals between the stationary body and rotating parts of drones, enabling smooth operation and precise control.Production Process:To ensure the highest quality and reliability, the production process of Twist Capsule Slip Rings entails several critical steps:1. Design and Engineering: The slip ring's design is meticulously engineered using advanced CAD software, taking into consideration factors such as size, materials, number of circuits, and rotational speed requirements.2. Component Selection: High-quality materials, such as gold alloy, stainless steel, and specialized plastics, are carefully chosen to ensure optimum electrical conductivity, durability, and resistance to wear and tear.3. Precision Manufacturing: Utilizing cutting-edge technologies like CNC machining and automated assembly, the slip rings are manufactured with utmost precision, maintaining tight tolerances for seamless operation.4. Quality Testing: Rigorous quality control tests are conducted throughout the manufacturing process to guarantee the slip rings' performance and durability. These assessments include electrical testing, rotational speed testing, and vibration testing.5. Final Inspection and Packaging: After passing all quality tests, the Twist Capsule Slip Rings undergo a final inspection, where each unit is examined for defects. They are then carefully packaged to ensure damage-free delivery.Conclusion: Twist Capsule Slip Rings have revolutionized connectivity in numerous industries by offering a compact yet powerful solution for seamless data and power transmission. With their exceptional features, like miniature design, multi-channel signal transmission, and high rotational speed capabilities, these slip rings are redefining the concept of connectivity. So, whether it's robotics, medical equipment, surveillance systems, or drones, Twist Capsule Slip Rings are paving the way towards a more connected and efficient future.

Mini Slip Ring with Flange for Data and Video Signals Transmission when 360 Rotating

Senring Electronics Co., Ltd recently introduced its latest product, the Capsule Slip Ring, a mini slip ring with a flange design. This product provides a solution for small and medium-sized equipment that requires data and video signals transmission while rotating 360 degrees.The Capsule Slip Ring boasts of several features tailored to meet the needs of rotating equipment, including low torque, low loss, and low electric noise. The product has been manufactured to cater to the ever-increasing demand for equipment that operates with rotational movements while transmitting data and video signals. The mini slip ring with flange design has become an indispensable component of modern technology and innovation, particularly in the automation and robotics industry.Senring Electronics Co., Ltd is a leading designer and manufacturer of slip rings that have been designed to offer solutions to a wide range of industrial applications. The company is renowned for its immense technological proficiency and state-of-the-art equipment that ensures the production of high-quality products. Senring's expertise has been demonstrated through its production of Capsule Slip Ring, a product that offers high-performance characteristics required for transmitting critical signals of the rotating devices.The Capsule Slip Ring has several benefits that make it a perfect fit for small and medium-sized equipment that require rotational movements. The low torque feature of the product reduces the wear and tear caused by rotational movements of the device. The minimization of friction limits the level of maintenance required to keep the device operational. In addition, the low-loss feature ensures that the device functions efficiently by transmitting signals with minimal power loss, thus saving energy costs.The Capsule Slip Ring is also designed with low electric noise features, a characteristic that is beneficial for devices that operate in an environment with a high level of electromagnetic interference (EMI). The low electric noise levels ensure high-quality data transmission signals, eliminating errors that may arise from electromagnetic interference.The flange design of the Capsule Slip Ring makes it easy to install in small and medium-sized equipment without interfering with their operations. The design allows for easy disassembly and repair of the device without dismantling the entire assembly.Senring Electronics Co., Ltd is a company renowned for its commitment to quality and meeting its clients' needs. The Capsule Slip Ring is a product that meets the high-quality standards that are synonymous with Senring products, providing an efficient solution for data and video signals transmission for equipment that requires rotational movements.In conclusion, the Capsule Slip Ring, manufactured by Senring Electronics Co., Ltd, serves as a solution to the ever-increasing demand for small and medium-sized equipment that require rotational movements while transmitting data and video signals. The product's low torque, low loss, low electric noise, and flange design make it an indispensable component of modern technology and innovation, particularly in the automation and robotics industry. Senring Electronics Co., Ltd has once again demonstrated its technological proficiency and commitment to quality through its latest product, the Capsule Slip Ring, a product that meets the changing needs of the industrial sector.

Reliable and Efficient Slip Rings for Power, Signal, and Data Transmission with Advanced Gigabit Ethernet Technology

Slip Rings: The Backbone of Reliable Power, Signal, and Data TransmissionIn today's fast-paced world, reliable transmission of power, signals, and data is vital to the functioning of various industries. This is where slip rings come into the picture. A slip ring is an electromechanical component that is used to transmit power, signals, and data from a stationary component to a rotating component. Slip rings have been around for over a century and have revolutionized the way power, signals, and data are transmitted.High Protection Slip Rings by Kbler GroupKbler Group is a company that has been manufacturing slip rings for more than 50 years. They specialize in the production of high-quality slip rings and other related components. Kbler Group's slip rings are renowned for their reliability and long service life. The company has recently launched a range of High Protection Slip Rings that are designed to withstand harsh environmental conditions and provide uninterrupted transmission of power, signals, and data.Features of High Protection Slip RingsThe High Protection Slip Rings by Kbler Group come with several features that make them a reliable choice for various industries. These slip rings are designed to offer high protection against dust, water, and chemicals. They come with an IP67 or IP68 protection rating, making them suitable for use in harsh outdoor environments.The Kbler slip rings also come with a modular design that makes them easy to install and maintain. The modular design also enables customization of the slip rings to specific requirements, making them suitable for a wide range of applications. These slip rings also come with Gigabit Ethernet transmission capabilities, making them ideal for data-intensive applications.Long Service LifeKbler Group's High Protection Slip Rings are designed to offer a long service life, even in harsh environmental conditions. The slip rings are made from high-quality materials that are designed to withstand extreme temperatures, shock, and vibration. The materials used are also resistant to wear and tear, ensuring long-lasting performance.Applications of High Protection Slip RingsThe High Protection Slip Rings by Kbler Group are suitable for use in various industries, including:1. Renewable Energy: High Protection Slip Rings are ideal for use in wind turbines and solar panels, where they are used to transmit power from the stationary component to the rotating component.2. Industrial Automation: Slip rings are used in various industrial automation applications, including packaging, printing, and robotics. High Protection Slip Rings are ideal for use in these applications, which often involve harsh environmental conditions.3. Medical Equipment: Slip rings are used in various medical equipment, including MRI machines and ultrasound machines. High Protection Slip Rings are suitable for use in these machines, where transmission of power and data is critical.ConclusionIn conclusion, slip rings are an essential component in the transmission of power, signals, and data. Kbler Group's High Protection Slip Rings are designed to offer high-performance, reliable transmission in harsh environmental conditions. Their modular design, long service life, and Gigabit Ethernet capabilities make them suitable for various industries, including renewable energy, industrial automation, and medical applications. If you're looking for a reliable slip ring for your application, consider Kbler Group's High Protection Slip Rings.

Enhancing Signal Transfer Efficiency: A Comprehensive Guide on Integrated Slip Rings

article for an engineering magazine.Integrated Slip Ring: Redefining Connectivity and PrecisionThe field of engineering is a world of innovation and diversity, where every day, new technologies are being developed to meet the rapidly growing needs of industries. The demand for better signal transmission, rotational speed, and precision is crucial to the success of various engineering designs and systems. And this is why integrated slip rings have become a vital component in many diverse applications.Integrated slip rings have made significant contributions to the fields of automation, robotics, aerospace and defense, medical equipment, and many other industries. These devices provide a reliable and robust means of transmitting electrical power, control signals, and data between rotating and stationary components of a system or equipment. They are used to transmit signals to the rotating parts of the machines without creating disruptions in the signal or causing any data loss as the machine moves.One of the leading manufacturers of slip rings has come up with an improved version that is setting new standards in the industry. With a mission to provide the best solutions to their customers, this company has been designing and producing slip rings for over 20 years. Today, they are proud to introduce their latest innovation to the market- Integrated Slip Ring (ISR), a new slip ring design that is redefining connectivity and precision.So, what makes Integrated Slip Rings unique?The key feature of ISR is its compatibility with a wide range of applications. ISR is designed with the latest control circuits, signal processing, and materials technologies, making it adaptable to different dimensions, contact configurations, and specific requirements of equipment. It is tailored to suit the precision and high-speed demands of modern industrial applications while retaining the capacity to handle high voltage and current transmission.ISR is built with the latest technology in slip ring design, aiming for perfect execution, quality, and compatibility. The ISR is a highly reliable slip ring that has been laboratory tested to operate at high speed, precision, and endurance. Its advanced transmission technology ensures minimal signal degradation, no electrical noise, and no interference with the transmitted signal. The perfect balance of power and signal transmission is guaranteed with a slip ring defined by its simplicity of design and practicality.ISR's designers had a vision to overcome the common problems of slip rings in many applications. In conventional slip rings, when signals are transmitted across the rotating parts, contact brushes create wear and tear, which then produces signal jitter and interference. Likewise, the friction generated in traditional slip rings can sometimes lead to the loss of control signals and data, which could potentially compromise the safety and quality of operations.Integrated Slip Ring eliminates these concerns with its advanced design. ISR has no brushes or contacts, thus negligible wear or tear during the rotation, while the continuous rotation of the slip ring can guarantee zero signal loss or jitter.Integrated Slip Ring is engineered to meet the requirements of a range of applications. The slip ring is designed to withstand high current and voltage requirements, and it is equipped with durable materials and sophisticated elements that ensure reliability, robustness, and safety.The ISR model also incorporates temperature-responsive components to regulate the device's performance during extreme ambient conditions. The modular design of the ISR makes it easy to integrate with other components in any machine or equipment, thus adding significant value to the efficiency and reliability of industrial operations.In conclusion, the integrated slip ring has revolutionized the field of engineering by establishing a reliable and precise means of transmitting power, control signals, and data. ISR is a highly reliable and long-lasting slip ring that has been designed with the latest technology and engineering expertise to meet the stringent demands of modern industrial applications. The ISR's ability to adapt to different applications, advanced transmission technology, zero signal loss/jitter, and improved temperature resistance make it the best choice for any industrial application that requires precision, robustness, and reliability. With ISR, industrial automation, aerospace and defense, oil and gas, medical, packaging, and many other industries are guaranteed to receive the best, advanced slip ring technology.