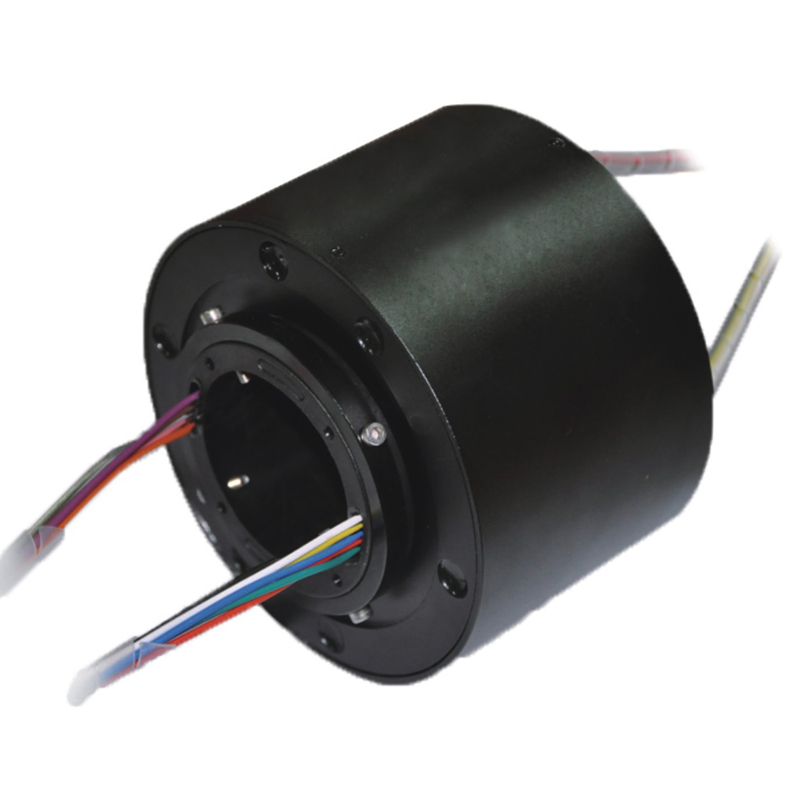

High-Quality Hydraulic Slip Rings for Industrial Use

By:Admin

In today's fast-paced world, the demand for efficient power and data transmission technology is higher than ever. With the increasing complexity of machinery and equipment, the need for reliable and durable slip rings has become a top priority for many industries. This is where the innovative Hydraulic Slip Rings, developed by a renowned company in the field, come into the picture.

(insert company name) is a leading provider of advanced solutions for power and data transmission in various industrial sectors. With a strong focus on research and development, the company has consistently delivered cutting-edge products that have set new benchmarks in the industry. One of their most notable innovations is the Hydraulic Slip Rings - a technology that promises to revolutionize the way power and data are transmitted in modern machinery.

Traditional slip rings, which are commonly used in machinery and equipment, have limitations when it comes to high-speed and high-power applications. They are prone to wear and tear, leading to frequent maintenance and downtime. However, with the introduction of Hydraulic Slip Rings, these limitations are effectively addressed.

Hydraulic Slip Rings make use of a hydraulic fluid-based system to transmit power and data, offering a number of advantages over traditional slip rings. The fluid-based design allows for a continuous and uninterrupted flow of power and data, making it ideal for high-speed and high-power applications. Additionally, the use of hydraulic fluid ensures smooth and precise transmission, reducing the risk of wear and tear.

One of the key features of Hydraulic Slip Rings is their ability to operate in harsh environments. Their robust design and durable construction make them suitable for use in extreme conditions, such as high temperatures, high pressures, and corrosive environments. This makes them an ideal choice for industries such as aerospace, defense, oil and gas, and marine, where reliability and performance are critical.

Another notable advantage of Hydraulic Slip Rings is their scalability. They can be customized to meet specific requirements, allowing for seamless integration into a wide range of machinery and equipment. This flexibility makes them a versatile solution for various applications, from small-scale machinery to large industrial systems.

The use of Hydraulic Slip Rings also contributes to improved operational efficiency and reduced maintenance costs. The continuous and smooth transmission of power and data minimizes the need for frequent repairs and replacements, resulting in reduced downtime and increased productivity. This, in turn, translates to cost savings for businesses relying on machinery and equipment for their operations.

The potential applications of Hydraulic Slip Rings are vast, ranging from robotics and automation to renewable energy and beyond. They have the capability to revolutionize the way power and data are transmitted in modern machinery, paving the way for enhanced performance and reliability across various industries.

(insert company name)’s commitment to innovation and excellence is evident in the development of Hydraulic Slip Rings. By leveraging their expertise in power and data transmission, the company has introduced a pioneering technology that has the potential to transform the way industries operate.

As the demand for advanced power and data transmission solutions continues to grow, (insert company name)’s Hydraulic Slip Rings are poised to lead the way in setting new standards for reliability, durability, and performance. With a strong track record of delivering innovative solutions, the company is well-positioned to drive the adoption of Hydraulic Slip Rings across diverse industrial sectors, shaping the future of power and data transmission.

Company News & Blog

Quality Slip Ring Supplier in India for Industrial Solutions

India has been witnessing an increased demand for slip rings in various industries such as automation, robotics, aerospace, defense, and consumer electronics. In response to this demand, a leading slip ring supplier in India has been making efforts to meet the growing needs of the market by expanding their production capacity and offering innovative solutions to their customers.The company, with a rich history of over 20 years in the industry, has established itself as a reliable and trusted supplier of high-quality slip rings. They have built a strong reputation for delivering cutting-edge solutions to meet the complex requirements of industries such as automation, robotics, and aerospace.With a state-of-the-art manufacturing facility equipped with advanced machinery and a team of skilled engineers, the company has been able to cater to the diverse needs of its customers. Their commitment to quality and continuous innovation has made them a preferred choice for slip rings in India.The company has also been proactive in understanding the specific needs of different industries and customizing their products accordingly. They have a dedicated team of experts who work closely with customers to provide tailored solutions that meet their exact requirements. This focus on customization has set the company apart from its competitors and has helped them build long-lasting relationships with their clients.In addition to their strong focus on innovation and customization, the company has also invested significantly in research and development. They have a team of experienced R&D professionals who are constantly working on developing new and improved slip ring solutions. This commitment to R&D has enabled the company to stay ahead of the curve and offer cutting-edge products to their customers.In line with the growing demand for slip rings in India, the company has recently expanded its production capacity to meet the increasing needs of the market. They have invested in new machinery and technology to enhance their manufacturing capabilities and increase their production output. This expansion reflects their commitment to supporting the growth of various industries in India by providing them with reliable and high-quality slip ring solutions.Furthermore, the company has also been focusing on strengthening its distribution network to ensure that their products reach customers across the country efficiently. They have partnered with leading distributors and suppliers to make their products more accessible to industries in different regions of India. This strategic approach to distribution has enabled the company to reach a wider customer base and cater to the diverse needs of various industries.The company's dedication to quality, innovation, customization, and expansion reflects its strong commitment to serving the growing demand for slip rings in India. They have positioned themselves as a reliable and trusted supplier that delivers top-notch solutions to meet the evolving needs of industries such as automation, robotics, aerospace, defense, and consumer electronics.As the demand for slip rings continues to rise in India, the company is well-positioned to capitalize on this growth and further strengthen its position as a leading supplier in the country. With its focus on innovation, customization, and expansion, the company is poised to play a significant role in supporting the development of various industries in India by providing them with advanced and reliable slip ring solutions.

Discover the Benefits of a Rotary Electrical Joint

Rotary Electrical Joint, a pioneering company in the field of advanced electrical connectors, has announced a breakthrough in their technology that promises to revolutionize the way electrical connections are made in various industries. The company has developed a new rotary electrical joint that offers superior performance and reliability, making it an ideal solution for a wide range of applications.With a strong focus on research and development, Rotary Electrical Joint has established itself as a leader in the industry, continuously pushing the boundaries of what is possible in the field of electrical connectors. The company's team of highly skilled engineers and scientists are dedicated to developing innovative solutions that address the evolving needs of their customers.The new rotary electrical joint from Rotary Electrical Joint offers several key advantages over traditional electrical connectors. Its unique design allows for smooth rotation, enabling the transfer of electrical power or signals without the need for additional cables or wiring. This innovation not only reduces the risk of signal loss and interference but also simplifies the installation and maintenance process, ultimately leading to cost savings for customers.In addition, the rotary electrical joint boasts exceptional durability and reliability, making it perfectly suited for use in harsh environments and demanding applications. Its robust construction and advanced materials ensure long-term performance, even in the most challenging conditions. As a result, industries such as aerospace, automotive, industrial automation, and renewable energy can benefit from this groundbreaking technology."We are thrilled to introduce our new rotary electrical joint, which represents a significant advancement in the field of electrical connectors," said [Spokesperson], [Title] at Rotary Electrical Joint. "This innovative solution embodies our commitment to delivering high-quality, reliable products that meet the needs of our customers. We believe that this technology will have a transformative impact across various industries, opening up new possibilities for improved efficiency and performance."Furthermore, Rotary Electrical Joint has a strong track record of providing custom solutions to meet the unique requirements of their clients. The company's team works closely with customers to understand their specific challenges and develop tailored solutions that address their needs. This customer-centric approach has earned Rotary Electrical Joint a reputation for excellence and reliability, making them a trusted partner for many leading organizations.The introduction of the new rotary electrical joint further solidifies Rotary Electrical Joint's position as an industry leader, showcasing their innovative capabilities and commitment to driving progress in the field of electrical connectors. The company's dedication to research, development, and customer satisfaction sets them apart as a key player in the market, with a continued focus on creating value for their clients.As Rotary Electrical Joint continues to push the boundaries of what is possible in the field of electrical connectors, they remain committed to pursuing new opportunities and partnerships that will further propel them ahead in the industry. With a strong foundation built on innovation and excellence, the company is poised to continue shaping the future of electrical connections and setting new standards for performance and reliability.

Global Contactless Inductive Slip Ring Market: Insights, Trends, and Outlook to 2026

Contactless Inductive Slip Ring Market: Revolutionizing ConnectivityIn today's fast-paced world, where technology is advancing at an unprecedented rate, connectivity plays a vital role in various industries. Industries such as robotics, aerospace, and semiconductors rely heavily on seamless communication and data transfer. This is where contactless inductive slip rings come into play. The global contactless inductive slip ring market is experiencing significant growth, driven by innovations and advancements in the field of wireless power transmission.A slip ring, also known as a rotary electrical interface, is an electromechanical device that enables the transmission of power and signals between stationary and rotating components. Traditional slip rings rely on physical brushes or wires that can wear out over time, leading to performance degradation and maintenance issues. Contactless inductive slip rings, on the other hand, offer a revolutionary solution by eliminating the need for physical contact between the stationary and rotating parts.Inductive slip rings utilize electromagnetic coupling for power and signal transmission, enabling high-speed data transfer and power delivery without the concerns associated with traditional slip rings. By employing inductive coupling, these slip rings provide several advantages, including reduced friction, enhanced reliability, and increased lifespan. Moreover, contactless inductive slip rings ensure efficient power transmission, as there is no energy loss due to physical contact.The global contactless inductive slip ring market is witnessing robust growth due to the increasing need for reliable connectivity solutions in various industries. The rise in automation and the demand for efficient power and data transfer in robotics and industrial machinery are major drivers of market growth. Contactless inductive slip rings offer a compact and reliable solution for robotic arms, enabling seamless motion control and data exchange.Furthermore, the aerospace and defense sector is adopting contactless inductive slip rings for applications such as navigation systems, radar antennas, and communication systems. These slip rings ensure a reliable and continuous flow of power and signals, even in harsh environmental conditions. The ability of inductive slip rings to operate at high speeds and handle large amounts of data makes them ideal for aerospace applications.The semiconductor industry is another major consumer of contactless inductive slip rings. The continuous advancements in semiconductor technology, including wafer handling and testing, require highly reliable and high-speed connectivity solutions. Inductive slip rings provide a non-contact solution that minimizes signal interference and data loss, ensuring optimal performance in semiconductor manufacturing processes.In terms of geographical distribution, North America is expected to dominate the contactless inductive slip ring market. The region is home to several leading technology companies and is at the forefront of technological advancements. The automotive and aerospace industries in North America are expanding and demanding innovative connectivity solutions, further driving the market growth. Europe and Asia-Pacific are also witnessing significant growth, propelled by advancements in industrial automation and rapid industrialization.In conclusion, contactless inductive slip rings are revolutionizing connectivity in various industries by providing reliable and efficient power and signal transmission. These slip rings offer numerous advantages over traditional slip rings, including reduced friction, enhanced reliability, and increased lifespan. The global contactless inductive slip ring market is experiencing robust growth, driven by the increasing need for seamless and high-speed connectivity in industries such as robotics, aerospace, and semiconductors. As technology continues to evolve, contactless inductive slip rings will play a crucial role in enabling efficient and reliable communication and data transfer.

High-quality Capsule Slip Ring for Reliable Rotational Transmission

Capsule Slip Ring Market: OverviewThe global Capsule Slip Ring market report offers a significant assistant that prepares market participants to work on the strategies for growth and while considering this report, the business structure has been developed to delve into the market and find ways to grow and be successful. It provides in-depth knowledge about all the market's competitive landscapes, it outlines the market's future trends, and it also provides insight into the companies' active in the market. Furthermore, the report provides a comprehensive analysis of the global Capsule Slip Ring market from the company profiles to the competitive landscape.The global Capsule Slip Ring market report offers a comprehensive overview of the various aspects of the market, including market segmentation, market dynamics, market size, supply and demand, and the competitive landscape. The report provides an in-depth analysis of the market dynamics, including the drivers, restraints, opportunities, and challenges. It also provides a comprehensive analysis of the market size, supply and demand, and the competitive landscape.The report provides a detailed analysis of the global Capsule Slip Ring market based on the company profiles, the competitive landscape, and the market's future trends. The report also provides an in-depth analysis of the market dynamics, including the drivers, restraints, opportunities, and challenges. Companies ProfiledThe global Capsule Slip Ring market report profiles some of the key players in the market and provides information about their products and services, business strategies, and financial performance. Some of the key players profiled in the report include [company name removed], Moog, Cobham, Stemmann, MERSEN, United Equipment Accessories, Conno, Morgan, Cavotec SA, and JINPAT Electronics. The report also provides information about the companies' market share, sales and revenue, and market share. The report also provides information about the companies' market share, sales and revenue, and market share.Market SegmentationThe global Capsule Slip Ring market report provides a comprehensive analysis of the market segmentation, including the product types, applications, and geographic regions. The report also provides an in-depth analysis of the market size, supply and demand, and the competitive landscape. The report also provides a comprehensive analysis of the market's future trends, including the drivers, restraints, opportunities, and challenges.By Type:• Standard Capsule Slip Ring• Miniature Capsule Slip Ring• OthersBy Application:• Defense & Aerospace• Industrial & Commercial• Testing Equipment• OthersRegional AnalysisThe global Capsule Slip Ring market report provides a comprehensive analysis of the market's regional landscape, including the Americas, Europe, Asia Pacific, and the Middle East and Africa. The report also provides information about the market's future trends, including the drivers, restraints, opportunities, and challenges.Market DynamicsThe global Capsule Slip Ring market report provides an in-depth analysis of the market's dynamics, including the drivers, restraints, opportunities, and challenges. The report also provides information about the market's future trends, including the drivers, restraints, opportunities, and challenges.The global Capsule Slip Ring market report provides a comprehensive analysis of the market's competitive landscape, including the company profiles and the competitive landscape. The report also provides information about the market's future trends, including the drivers, restraints, opportunities, and challenges.

Top Quality Slip Rings for Your Electrical Equipment

In today’s fast-paced world, the demand for reliable and efficient technology is constantly on the rise. Companies are always looking for innovative solutions to improve their products and services. A key component in many technologies is slip rings, which play a crucial role in transmitting power and data in rotating systems. This is where {company name} comes into the picture. They are a leading provider of slip rings, and their cutting-edge technology has been making waves in various industries.Established in {year}, {company name} has quickly carved a niche for itself in the field of slip ring technology. The company has a team of highly skilled engineers and technicians who are dedicated to pushing the boundaries of innovation. Their commitment to quality and customer satisfaction has earned them a stellar reputation in the industry. {company name} takes pride in offering a wide range of slip rings with different specifications to cater to the diverse needs of their clients.One of the key features that sets {company name} apart from its competitors is its focus on research and development. The company is constantly investing in new technologies and methodologies to stay ahead of the curve. This dedication to innovation has allowed {company name} to develop state-of-the-art slip rings that are not only reliable but also highly efficient. Their products have been widely adopted in various applications, including robotics, medical equipment, aerospace, and many more.In addition to their technological prowess, {company name} also takes great pride in its commitment to customer service. The company understands that each client has unique requirements, and they go above and beyond to provide personalized solutions. Whether it’s a standard slip ring or a custom-designed one, {company name} works closely with its clients to ensure that they get exactly what they need. Their responsive customer support team is always ready to answer any queries and provide technical assistance whenever necessary.Moreover, {company name} places a strong emphasis on quality control and assurance. Each slip ring undergoes rigorous testing and inspection before it is shipped out to the customer. This meticulous attention to detail guarantees that every product that leaves the {company name} facility meets the highest standards of quality and reliability. As a result, their clients can have peace of mind knowing that they are investing in a product that will deliver exceptional performance.Looking towards the future, {company name} is committed to furthering its position as a leader in slip ring technology. With a strong focus on innovation and customer satisfaction, the company is continuously striving to develop new and improved solutions for its clients. {company name} also aims to expand its reach to new markets and industries, while also strengthening its relationships with existing clients.In conclusion, {company name} has established itself as a powerhouse in the field of slip ring technology. Their unwavering commitment to innovation, quality, and customer service has set them apart from the competition. As technology continues to evolve, {company name} is well-positioned to lead the charge and set new benchmarks in the industry. Their dedication to excellence and their passion for delivering cutting-edge solutions make them a force to be reckoned with.

Benefits of Through Bore Slip Rings in Industrial Applications

Through Bore Slip Ring Market Growth, Trends, and Forecasts (2021 - 2026)The global Through Bore Slip Ring market is expected to grow at a CAGR of over 5% during the forecast period (2021-2026). The through bore slip ring, also known as a rotary electrical interface, is used to transfer power, electrical signals, and data from a stationary to a rotating structure. This technology has a wide range of applications, including in wind turbines, packaging equipment, industrial machinery, and medical equipment.The increasing demand for automation and robotics in various industries is one of the key factors driving the growth of the through bore slip ring market. With the rise of Industry 4.0, there is a growing need for seamless connectivity between stationary and rotating components in manufacturing processes. Through bore slip rings facilitate this connectivity, enabling the transfer of power and signals without the need for cables or wires.Additionally, the increasing adoption of renewable energy sources such as wind and solar power is expected to drive the demand for through bore slip rings. These slip rings are used in wind turbines to transfer power and data from the stationary base to the rotating blades, ensuring efficient and reliable operation.Furthermore, technological advancements in through bore slip ring designs are leading to the development of high-performance, compact, and lightweight solutions. These advanced slip rings offer improved reliability, longer service life, and enhanced capabilities to transfer power and signals in demanding industrial environments.Based in (Company Location), (Company Name) is a leading manufacturer of through bore slip rings, offering a wide range of standard and custom solutions for various applications. With over (number) years of experience in the industry, (Company Name) has established itself as a trusted supplier of high-quality slip rings to customers around the world.The company's through bore slip rings are designed to meet the rigorous demands of modern industrial and commercial applications. (Company Name) utilizes state-of-the-art manufacturing processes and quality control measures to ensure that its slip rings meet international standards for performance and reliability. The company's team of experienced engineers and technical staff work closely with customers to develop custom solutions that meet their specific requirements.In addition to standard through bore slip rings, (Company Name) also offers a range of accessories and services to support its customers. This includes slip ring assemblies, mounting brackets, and technical support for installation and maintenance. The company's commitment to providing comprehensive solutions sets it apart from competitors in the market.As a global supplier, (Company Name) has a strong presence in key regions such as North America, Europe, and Asia Pacific. The company has established a robust distribution network and partnerships with leading industrial and automation companies to ensure the availability of its products worldwide. This extensive reach allows (Company Name) to effectively serve a diverse customer base across different industries.Looking ahead, (Company Name) is focused on further enhancing its product portfolio with advanced through bore slip ring technologies. The company is investing in research and development to address the evolving needs of its customers and stay ahead of market trends. By leveraging its expertise and capabilities, (Company Name) aims to continue driving innovation and delivering value to its customers in the through bore slip ring market.In conclusion, the global through bore slip ring market is poised for significant growth driven by the increasing demand for automation, renewable energy, and advanced industrial machinery. (Company Name) is well-positioned to capitalize on these opportunities with its high-quality products, technical expertise, and global presence. As the market continues to evolve, (Company Name) remains committed to providing reliable and innovative solutions to meet the evolving needs of its customers.

Essential Parts for Slip Rings: What You Need to Know

On the forefront of slip ring technology, {company name} has been a leading manufacturer of high-quality slip ring parts for a wide range of industrial applications. With a strong dedication to innovation, quality, and customer satisfaction, {company name} has continuously set the standard in the slip ring industry. Recently, the company has unveiled its latest line of slip ring parts, which promises to deliver even greater performance and reliability.One of the key features of {company name}'s slip ring parts is their ability to transmit power, electrical signals, and data from a stationary to a rotating structure. This is achieved through a combination of advanced engineering techniques and high-quality materials, ensuring that the slip ring parts are capable of withstanding the most demanding operating conditions. This versatility makes {company name}'s slip ring parts suitable for use in a wide range of industries, including aerospace, defense, medical, and robotics.In addition to their exceptional performance, {company name}'s slip ring parts are also designed with ease of installation and maintenance in mind. This ensures that customers can quickly and efficiently integrate the slip ring parts into their existing systems, minimizing downtime and increasing productivity. Furthermore, {company name} offers comprehensive technical support and customer service, ensuring that customers have access to the expertise and assistance they need to maximize the performance of their slip ring parts.{company name} has also been at the forefront of sustainability and environmental responsibility in the manufacturing of slip ring parts. The company has implemented a range of eco-friendly initiatives, from using recyclable materials in their products to reducing energy consumption in their manufacturing processes. This commitment to sustainability not only benefits the environment but also ensures that {company name}'s slip ring parts are manufactured to the highest possible standards.Furthermore, {company name} has established itself as a global leader in the slip ring industry, with a strong presence in markets around the world. The company's dedication to excellence and innovation has earned it a reputation for reliability and performance, making it the preferred choice for customers seeking high-quality slip ring parts.Overall, {company name}'s new line of slip ring parts represents a significant advancement in the industry, offering unmatched performance, reliability, and versatility. With a strong commitment to innovation, quality, and customer satisfaction, {company name} continues to set the standard in the slip ring industry, providing customers with the advanced solutions they need to thrive in today's competitive market.

Effective Slip Ring Maintenance Tips for Long-Term Reliability

In today's fast-paced and highly automated world, the importance of slip ring maintenance cannot be overstated. Slip rings are essential components in a wide range of mechanical and electrical systems, providing the necessary connection for the transmission of power and signals between stationary and rotating parts. Proper maintenance ensures the longevity and performance of these critical components, ultimately contributing to the efficiency and reliability of the overall system.{Company Name} is a leading supplier of slip rings, offering an extensive range of high-quality products for various industrial applications. With a strong commitment to innovation and customer satisfaction, {Company Name} has established itself as a trusted partner for businesses seeking reliable slip ring solutions. The company's expertise and dedication to excellence make it a go-to source for slip ring maintenance best practices and advice.Effective slip ring maintenance begins with a thorough understanding of the components and their operational requirements. It is essential for businesses to implement a regular inspection schedule to identify any signs of wear, damage, or potential issues that may impact the performance of the slip rings. This involves checking for carbon deposits, worn brushes, loose connections, and any other abnormalities that could hinder the proper function of the slip rings.{Company Name} recognizes the importance of proactive maintenance and offers valuable insights into the best practices for slip ring maintenance. The company emphasizes the significance of regular cleaning to remove dust, debris, and other contaminants that can compromise the integrity of the slip rings. Additionally, lubrication of the moving parts is crucial to minimize friction and wear, ultimately extending the lifespan of the components.Furthermore, {Company Name} provides guidance on the importance of conducting electrical tests to ensure the integrity of the connections and the transmission of signals. By identifying and addressing any potential electrical issues, businesses can mitigate the risk of downtime and costly repairs associated with slip ring failures.In addition to these proactive measures, {Company Name} emphasizes the value of having a comprehensive maintenance plan in place. This includes keeping detailed records of inspections, repairs, and replacements to track the lifecycle of the slip rings and identify any trends or recurring issues that may require further attention. By establishing a systematic approach to maintenance, businesses can effectively manage the upkeep of their slip rings and minimize the risk of unexpected failures.{Company Name} also recognizes that not all businesses may have the expertise or resources to manage slip ring maintenance internally. As such, the company offers professional maintenance services to assist businesses in upholding the performance and reliability of their slip ring systems. With a team of skilled technicians and engineers, {Company Name} is equipped to conduct thorough inspections, perform necessary repairs, and provide tailored maintenance solutions to meet the specific needs of its customers.As a trusted partner for slip ring solutions, {Company Name} is dedicated to supporting businesses in optimizing the performance and longevity of their slip ring systems. With a strong emphasis on proactive maintenance practices and a commitment to excellence, the company is well-positioned to guide businesses in implementing effective maintenance strategies to safeguard the integrity of their operations.In conclusion, slip ring maintenance is a critical aspect of ensuring the reliability and performance of mechanical and electrical systems. {Company Name} stands as a reliable source of expertise and support, offering valuable insights and professional maintenance services to help businesses uphold the integrity of their slip ring systems. By prioritizing proactive maintenance practices and implementing comprehensive maintenance plans, businesses can optimize the longevity and efficiency of their slip rings, ultimately minimizing the risk of unexpected failures and costly downtime.

Innovative Manufacturer Creates High-Quality Products for Various Industries

Forj Manufacturer is a leading company in the field of manufacturing and supplying high-quality industrial components for various applications. With a strong emphasis on innovation and customer satisfaction, Forj Manufacturer has established a strong reputation for delivering superior products that meet the highest industry standards.Recently, Forj Manufacturer has introduced a new line of industrial components that are designed to enhance the efficiency and reliability of manufacturing processes. These new components have been specifically developed to address the evolving needs of modern industries, and are set to revolutionize the way that industrial processes are carried out.One of the key features of the new industrial components is their advanced material composition, which offers enhanced durability and resistance to wear and tear. This is particularly important in industries where heavy machinery and equipment are used on a daily basis, as it ensures that the components can withstand the rigors of industrial operations without compromising their performance.Furthermore, the new components also boast improved precision and accuracy, which is essential for maintaining the high quality standards demanded by modern manufacturing processes. This level of precision is achieved through state-of-the-art manufacturing techniques and rigorous quality control measures, ensuring that each component meets the stringent requirements of its intended application.In addition to their technical superiority, the new industrial components from Forj Manufacturer are also designed with user-friendliness in mind. This includes features such as easy installation and maintenance, as well as compatibility with existing machinery and equipment. As a result, customers can seamlessly integrate these components into their existing operations without the need for extensive retooling or modification.The launch of these new industrial components has been met with great enthusiasm from Forj Manufacturer's customers, who recognize the significant impact that these products will have on their operations. Many have already expressed their interest in incorporating these components into their manufacturing processes, citing the potential for increased productivity and cost savings.Forj Manufacturer has also been proactive in providing comprehensive support and technical assistance to its customers who are adopting these new components. This includes on-site training and consultation services, as well as access to a dedicated team of experts who are on hand to address any issues or concerns that may arise during the implementation process.The introduction of these new industrial components is a testament to Forj Manufacturer's commitment to innovation and continuous improvement. By staying ahead of industry trends and investing in research and development, Forj Manufacturer is able to deliver cutting-edge solutions that empower its customers to stay competitive in today's rapidly evolving market.Looking ahead, Forj Manufacturer is poised to further expand its product offerings and market presence, as it continues to explore new opportunities for growth and diversification. With a strong focus on customer satisfaction and technological advancement, Forj Manufacturer is well positioned to remain a leader in the industrial components manufacturing industry for many years to come.