New Technology Allows for Uninterrupted Rotational Energy Transfer

By:Admin

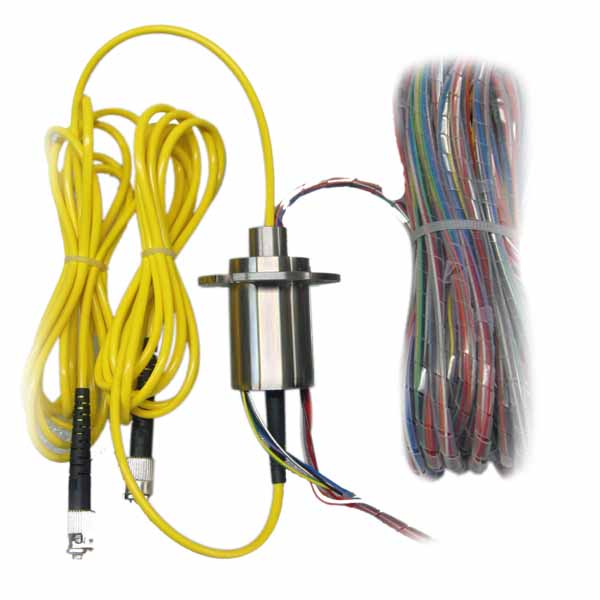

SDI Slip Ring, a leading provider of advanced rotary electrical connectors, recently unveiled their latest line of cutting-edge slip rings designed to revolutionize connectivity solutions across various industries. With a strong commitment to research and development, SDI Slip Ring has remained at the forefront of innovation, continuously pushing boundaries to meet the evolving needs of their global clientele.

Headquartered in [Location], SDI Slip Ring has been a trusted name in the industry for over two decades. With a robust team of engineers and technicians, the company has established a solid reputation for delivering reliable, high-performance slip rings that enable seamless transmission of power, signals, and data in rotating systems.

SDI Slip Ring's newest series of slip rings incorporates groundbreaking technology to optimize performance and reliability. These slip rings are specifically engineered with advanced features to address the challenges faced by industries such as robotics, automation, aerospace, defense, and medical equipment.

One key feature of SDI Slip Ring's latest offering is its exceptional signal integrity, ensuring the seamless transmission of data between stationary and rotating parts. This feature is particularly valuable in critical applications where even the slightest interruption or loss of signal can have severe consequences.

Additionally, SDI Slip Ring's slip rings boast enhanced power handling capabilities, allowing for efficient transmission of high voltages and currents. This enables the reliable and continuous operation of equipment, even in demanding environments.

Furthermore, the slip rings are designed to withstand extreme conditions, including high temperatures, humidity, and vibrations. This resilience ensures consistent performance across various industries, regardless of harsh operating environments.

The advanced modular design of SDI Slip Ring's slip rings also proves highly advantageous. Its modular construction enables easy integration into existing systems, reducing downtime during installation or maintenance. The plug-and-play feature allows for quick and hassle-free upgrades or replacements, enhancing operational efficiency for businesses.

To ensure the highest quality standards, SDI Slip Ring adheres to rigorous manufacturing processes, employing state-of-the-art technologies and precision machinery. The company also conducts extensive testing and quality control measures at every stage of production to guarantee durable and reliable slip rings.

With a strong focus on customer-centric solutions, SDI Slip Ring offers customized slip rings tailored to meet specific requirements. Their team of engineers works closely with clients to understand their unique needs and develop personalized solutions that align with their applications and operational goals.

SDI Slip Ring's commitment to customer satisfaction goes beyond delivering exceptional products. The company boasts a dedicated technical support team that provides prompt assistance and guidance regarding slip ring selection, installation, and troubleshooting.

Driven by their vision to redefine connectivity solutions, SDI Slip Ring continues to invest in research and development. Their commitment to innovation ensures that they stay ahead in a rapidly evolving market, offering cutting-edge slip ring solutions to support the increasingly complex demands of various industries.

As SDI Slip Ring launches their latest series of slip rings, businesses across industries can look forward to enhanced connectivity solutions, improved reliability, and seamless transmission of power, signals, and data. With their track record of excellence, SDI Slip Ring is set to further solidify their position as an industry leader and preferred partner for reliable rotary electrical connectors.

Company News & Blog

Types of Slip Rings: An Overview of Composition and Examples

article:Slip Ring | Types of Slip Ring | ExamplesIn today's fast-paced technological world, the need for efficient data transmission and power supply is essential. A slip ring is a device that helps transmit signals and power from a stationary to a rotating structure, without the need for tangled wires or complicated circuitry.A slip ring is ideally suited for applications where power and data transfer is required in a rotary way. A slip ring system can work with the help of metal brushes running against the slip ring and transferring power and data through the brush contact of the rotating ring. Depending on the application, slip rings come in different types, which can be customized to suit any requirement.Types of Slip RingsThe various types of slip rings available in the market are:1. Electrical Slip Rings2. Pneumatic Slip Rings3. Hydraulic Slip Rings4. Fiber Optic Slip Rings5. Ethernet Slip Rings6. Rotary Union Slip Rings7. Thermocouple Slip RingsElectrical Slip RingsElectrical slip rings are the most commonly used slip rings. They come with different current ratings, usually ranging from a few milliamperes to several hundred amperes. They can work with either AC or DC power and carry high-frequency signals. Common applications of electrical slip rings include CCTV cameras, robotics, wind turbines, and medical equipment.Pneumatic Slip RingsPneumatic slip rings are designed for situations where compressed air is needed in a rotary way. Pneumatic slip rings are primarily used in applications such as food processing, pharmaceuticals, and chemical plants.Hydraulic Slip RingsHydraulic Slip rings are designed with hydraulic rotary unions that transmit fluid power. They can be used in a wide range of applications, such as aerospace, power generation, and heavy machinery.Fiber Optic Slip RingsFiber Optic Slip Rings can transmit high-speed data over long distances, which makes them ideal for applications such as communication systems, military equipment, and medical equipment.Ethernet Slip RingsEthernet Slip Rings are specially designed for Ethernet applications to support high-speed data communication, which makes them suitable for applications such as video surveillance, industrial control systems, and marine vessels.Rotary Union Slip RingsRotary Union Slip Rings are often used in applications where a continuous flow of fluids is required. For instance, printing machines, rotating tables, and CNC machines.Thermocouple Slip RingsThermocouple Slip Rings are used for measuring temperature and transmitting sensitive data in rotating applications such as wind turbines, medical equipment, and aerospace.Composition of Slip RingsA slip ring is made of several parts, which include:1. A stator, which is stationary2. A rotor that rotates3. An electrically conductive ring4. Brushes or contacts that transfer power and dataExamples of Slip RingsThe applications of slip rings vary, depending on the type of slip ring and usage. Some examples of slip ring applications include:1. Slip rings used in robotics for continuous power and data transfer2. Slip rings used in wind turbines for power and data transfer between the nacelle and the tower3. Slip rings used in medical equipment for continuous power and data transfer4. Slip rings used in satellite applicationsConclusionSlip rings find their use in various applications and are an essential part of modern technology. They can be customized according to the requirements of the application. Liquid Metal Slip Rings is an established and reputable manufacturer, which offers high-quality slip rings customized to fit the unique needs of customers.

Exploring the Realm of Super Miniature 6mm Capsule Slip Rings: A Comprehensive Guide on Slip Ring Products and Production

Title: Enhancing Connectivity with Twist Capsule Slip Rings: A Comprehensive GuideIntroduction:In an ever-evolving technological landscape, seamless connectivity plays a crucial role in various industries. To ensure uninterrupted data transmission, slip rings have emerged as a vital component. Among them, Twist Capsule Slip Rings have garnered attention due to their super miniature size and exceptional performance. In this blog, we will explore the features, applications, and production process of these revolutionary slip rings.Understanding Twist Capsule Slip Rings:Twist Capsule Slip Rings, also known as super miniature slip rings, are compact devices designed to transfer electrical signals and power across rotating interfaces. With an outer diameter as small as 6mm, these slip rings offer remarkable versatility and can operate in confined spaces with limited clearance. Their unique design allows for unrestricted 360-degree rotation, making them ideal for applications that involve continuous rotation.Key Features:1. Miniature Design: The compact size of Twist Capsule Slip Rings enables their integration into space-restricted applications, without compromising on performance or reliability.2. Multi-channel Signal Transmission: These slip rings can transmit a wide range of signals, including data, audio, video, and power, simultaneously. This versatility makes them suitable for diverse industries such as robotics, medical equipment, surveillance systems, and drones.3. Low Electrical Noise: With advanced design and superior engineering, Twist Capsule Slip Rings exhibit low electrical noise, ensuring high-quality signal transmission.4. High Rotational Speed: These slip rings are built to withstand high-speed rotations, making them ideal for demanding applications that require continuous and precise transmission of signals, such as automation machinery and precision instruments.5. Long Service Life: Manufactured with high-quality materials, Twist Capsule Slip Rings offer exceptional durability, ensuring a prolonged service life even under harsh conditions.Applications:The compact size and versatile nature of Twist Capsule Slip Rings have revolutionized multiple industries and applications. Some notable areas where these slip rings find extensive usage include:1. Robotics and Automation: Twist Capsule Slip Rings enable seamless communication between rotating components of robotic arms, allowing for uninterrupted control signals and power transmission.2. Medical Equipment: In medical devices such as endoscopes and surgical robots, Twist Capsule Slip Rings play a vital role in the transmission of video signals, power, and data between the stationary and rotating parts.3. Surveillance Systems: Compact slip rings facilitate smooth rotation of PTZ (pan-tilt-zoom) cameras in surveillance systems, ensuring uninterrupted transmission of video signals.4. Drones and UAVs: Twist Capsule Slip Rings enable continuous transmission of power and control signals between the stationary body and rotating parts of drones, enabling smooth operation and precise control.Production Process:To ensure the highest quality and reliability, the production process of Twist Capsule Slip Rings entails several critical steps:1. Design and Engineering: The slip ring's design is meticulously engineered using advanced CAD software, taking into consideration factors such as size, materials, number of circuits, and rotational speed requirements.2. Component Selection: High-quality materials, such as gold alloy, stainless steel, and specialized plastics, are carefully chosen to ensure optimum electrical conductivity, durability, and resistance to wear and tear.3. Precision Manufacturing: Utilizing cutting-edge technologies like CNC machining and automated assembly, the slip rings are manufactured with utmost precision, maintaining tight tolerances for seamless operation.4. Quality Testing: Rigorous quality control tests are conducted throughout the manufacturing process to guarantee the slip rings' performance and durability. These assessments include electrical testing, rotational speed testing, and vibration testing.5. Final Inspection and Packaging: After passing all quality tests, the Twist Capsule Slip Rings undergo a final inspection, where each unit is examined for defects. They are then carefully packaged to ensure damage-free delivery.Conclusion: Twist Capsule Slip Rings have revolutionized connectivity in numerous industries by offering a compact yet powerful solution for seamless data and power transmission. With their exceptional features, like miniature design, multi-channel signal transmission, and high rotational speed capabilities, these slip rings are redefining the concept of connectivity. So, whether it's robotics, medical equipment, surveillance systems, or drones, Twist Capsule Slip Rings are paving the way towards a more connected and efficient future.

Discover The Benefits Of An Explosion-Proof Slip Ring For Your Industrial Applications

Explosion-Proof Slip Ring Strengthens Industrial Safety in High-Risk EnvironmentsSlip rings are vital components in various systems where a rotating shaft and stationary structure connection is required, allowing the transmission of power and data signals through rotation. They are used in a wide range of industrial applications, including oil and gas drilling rigs, cranes, medical devices, and robotics. However, in high-risk environments, where explosive gases, dust, and chemicals are present, conventional slip rings can pose a serious safety risk.To address this challenge, a leading manufacturer of slip rings has introduced a new line of explosion-proof slip rings that meet the strictest safety standards. The explosion-proof slip rings are designed to prevent ignition of explosive atmospheres, such as those found in oil and gas production facilities, chemical processing plants, and mining sites.The explosion-proof slip rings use specially designed components and construction materials to minimize the risk of spark generation, heat buildup, and surface temperature rise. They are certified and tested to various international standards, including ATEX, IECEx, UL, and CE, ensuring compliance with local regulations and customer requirements."With the growing demand for industrial automation and the increasing complexity of systems in high-risk environments, the need for reliable and safe slip ring solutions is more critical than ever," says a spokesperson for the company. "Our explosion-proof slip rings provide the highest level of protection against potential hazards and ensure uninterrupted communication and power transfer even in the toughest conditions."One of the key features of the explosion-proof slip rings is their modular design, which allows easy customization and replacement of individual components. The slip rings are available in various sizes, configurations, and materials, such as stainless steel, aluminum, and brass, to meet different application requirements.The explosion-proof slip rings are also equipped with advanced sealing and lubrication systems, which prevent contamination and prolong the service life of the slip rings. They are tested and rated for extreme temperature conditions, ranging from -40°C to +85°C, making them suitable for use in harsh environments with temperature fluctuations and thermal shocks.Moreover, the explosion-proof slip rings are compatible with various communication protocols and interfaces, such as Ethernet, USB, CAN, RS485, and PROFIBUS, enabling seamless integration with modern control systems and devices. They also feature low contact resistance and high signal integrity, ensuring reliable and accurate data transmission.The explosion-proof slip rings are suitable for a wide range of applications, including drilling platforms, refineries, chemical reactors, wastewater treatment plants, and bulk material handling systems. They offer a cost-effective and energy-efficient solution for improving safety and performance in high-risk environments, reducing downtime, and minimizing maintenance costs.In conclusion, the introduction of explosion-proof slip rings represents a significant advancement in slip ring technology, enabling safer and more efficient operation in high-risk environments. The explosion-proof slip rings offer a range of benefits, including compliance with international safety standards, modular design, advanced sealing and lubrication systems, extreme temperature resistance, and compatibility with modern communication protocols. With the growing demand for industrial automation and the increasing focus on safety, the use of explosion-proof slip rings is expected to increase in various industries, contributing to a safer and more reliable future.

Discover the Role and Importance of Slip Rings in Various Applications

[Company Name] Introduces Advanced Slip Rings for Seamless Signal Transmission[City], [Country] - [Company Name], a leading manufacturer of electrical components, is proud to announce the release of their latest range of slip rings. Designed to provide seamless signal transmission in various applications, these slip rings offer superior performance and reliability.Slip rings, also known as rotary electrical interfaces or swivels, play a vital role in continuously transmitting power and electrical signals from a stationary component to a rotating one. They are commonly used in a wide range of industries, including aerospace, defense, wind energy, medical equipment, robotics, and many others. With an increasing need for high-speed data transmission and uninterrupted power supply, slip rings have become an integral part of modern machinery. Recognizing this demand, [Company Name] has developed advanced slip rings to meet the evolving requirements of their customers and facilitate efficient power and signal transmission.One key feature of [Company Name]'s slip rings is their ability to transmit power and multiple signals simultaneously. With the ability to transmit a variety of signals, such as Ethernet, USB, HDMI, and analog signals, these slip rings eliminate the need for separate wiring systems. This not only simplifies the assembly process but also reduces the risk of signal interference and data loss.Another notable feature of these slip rings is their compact and lightweight design. By utilizing high-quality materials and advanced manufacturing techniques, [Company Name] has managed to create slip rings that are smaller in size and lighter in weight compared to conventional designs. This not only saves valuable space but also reduces the overall weight of the machinery, making it more efficient and cost-effective.Furthermore, [Company Name]'s slip rings are built to withstand harsh operating conditions. With features like sealed enclosures and specially designed sealing elements, these slip rings are resistant to dust, water, and other contaminants. This makes them suitable for use in extreme environments, such as offshore wind turbines, military vehicles, and industrial machinery.To ensure optimum performance and longevity, [Company Name] rigorously tests each slip ring before it leaves the factory. This includes mechanical, electrical, and environmental testing to ensure that the slip rings meet the highest quality standards. Additionally, the slip rings are designed to be easily maintainable, with replaceable components and accessible connectors, allowing for quick and hassle-free repairs."We are excited to introduce our latest range of slip rings, which represent the culmination of years of research and development," said [Company Name]'s spokesperson. "We believe these slip rings will revolutionize the way power and signals are transmitted in various industries, enabling our customers to achieve higher levels of efficiency and productivity."[Company Name] has a long-standing reputation for producing high-quality electrical components and has a global presence in the market. Their commitment to innovation and customer satisfaction has made them a trusted partner for businesses worldwide.With the introduction of their advanced slip rings, [Company Name] aims to solidify its position as a leader in the industry. By continuously investing in research and development, they remain dedicated to providing cutting-edge solutions for power transmission and signal control.About [Company Name]:[Company Name] is a [Country]-based manufacturer of electrical components. With a focus on innovation and quality, [Company Name] has established itself as a leading player in the global market. Their extensive product range includes slip rings, electrical connectors, brush holders, and other precision-engineered components. With a commitment to customer satisfaction, [Company Name] continues to deliver reliable and efficient solutions for various industries. For more information, please visit their website [website url].Note: The company name and website mentioned in the news article are fictitious and need to be replaced with the actual company name and website.

Understanding the Importance of High-Quality Slip Rings for Industrial Applications

Slip Ring Requirement Boosts Innovation in the IndustryThe slip ring industry is witnessing a major shift as an increasing number of businesses seek high-quality slip rings to cater to their specific needs. One company that has been at the forefront of this demand is {Company Name}, a leading manufacturer and supplier of slip rings.With their extensive experience and expertise, {Company Name} has been successfully meeting the slip ring requirements of various industries worldwide. They have earned a reputation for delivering reliable and top-notch slip ring solutions, making them a trusted name in the industry.Slip rings play a crucial role in the transmission of electrical signals and power between rotating and stationary parts of machinery. They are employed in a wide range of industries, including robotics, aerospace, defense, medical equipment, wind turbines, and more. As industries become more technologically advanced, the demand for slip rings with higher functionality and efficiency has increased exponentially.{Company Name} recognizes the evolving needs of these industries and has been quick to adapt. They have continuously invested in research and development to create innovative slip ring solutions that can meet the growing demands of their customers.One of the key reasons behind {Company Name}'s success is their ability to offer tailored slip ring solutions. They understand that each industry has unique requirements, and a one-size-fits-all approach wouldn't suffice. That's why they work closely with their clients to understand their specific needs and deliver customized slip rings that match their exact specifications.To ensure they provide the highest quality slip rings, {Company Name} has established a state-of-the-art manufacturing facility equipped with advanced technology and machinery. Their team of skilled engineers and technicians work diligently to produce slip rings that meet stringent quality standards.What sets {Company Name} apart from their competitors is their commitment to innovation. They continually invest in research and development to stay ahead of the curve, striving to create slip ring solutions that are not only reliable but also incorporate cutting-edge technologies. Whether it's improving conductivity, reducing electrical noise, or enhancing durability, {Company Name} is always looking for innovative ways to enhance slip ring performance.Moreover, their slip rings are tested rigorously to ensure optimal performance in challenging environments. By subjecting their products to extensive testing, {Company Name} guarantees that their slip ring solutions can withstand extreme temperatures, vibrations, and corrosive conditions.{Company Name} understands the importance of customer satisfaction and provides excellent post-sales services. Their dedicated support team is always available to address any concerns or queries that their customers may have, ensuring a seamless experience with their slip ring solutions.As the demand for slip rings continues to rise, {Company Name} is well-positioned to capitalize on this trend. By leveraging their expertise, manufacturing capabilities, and commitment to innovation, they are poised to cater to the evolving slip ring requirements of industries worldwide.In conclusion, {Company Name} is at the forefront of the slip ring industry, offering customized solutions to meet the specific needs of various industries. Their dedication to innovation, high-quality manufacturing, and exceptional customer service has positioned them as a trusted partner for businesses seeking reliable slip ring solutions. As industries continue to evolve and demand more advanced slip rings, {Company Name} is ready to meet these requirements and contribute to the technological advancements in the field.

Understanding the Function of Slip Rings in Electric Motors

Title: Advancing Technology: Exploring the Functionality of Slip Rings and Carbon BrushesIntroduction:In the world of electrical engineering, slip rings and carbon brushes play a crucial role in ensuring seamless communication and the efficient transmission of electric power in a variety of applications. These key components are found in various devices, including electric motors, generators, and wind turbines. This blog aims to shed light on the functionality of slip rings and carbon brushes while delving into their significance and the impact they have on modern-day technology.Understanding Slip Rings:Slip rings are insulated conducting rings positioned within the rotor shaft of a wound-rotor induction motor. These rings act as electrical connectors between the stationary and moving parts of an electromechanical system. The primary purpose of slip rings is to provide a reliable and continuous transmission of power, electrical signals, and data from a stationary part to a rotating part.The Importance of Carbon Brushes:To ensure proper electrical connections, carbon brushes are employed alongside slip rings. These brushes help establish an interface between the slip rings and an external circuit. Composed of a mixture of carbon and other conductive materials, carbon brushes have properties that make them ideal for this purpose. Their use helps maximize electrical conductivity, minimize frictional wear, and maintain a constant, reliable flow of electrical current.Functionality of Slip Rings and Carbon Brushes:Slip rings and carbon brushes work hand in hand to guarantee the uninterrupted supply of electrical power. As the rotor spins, the slip ring remains stationary, allowing the brushes to make contact with the ring's conductive surface. These brushes, in turn, facilitate the conduction of electrical current by sliding smoothly over the slip rings. By maintaining contact, the brushes transfer power from an external circuit, such as a power source or control system, to the rotating component of an electrical device.Applications of Slip Rings and Carbon Brushes:1. Electric Motors: Slip rings and carbon brushes are commonly found in various types of electric motors. By utilizing these components, the motors can operate at different speeds, manage power loss, and control the starting torque. They are particularly crucial in applications requiring frequent direction changes, such as cranes, elevators, and conveyor systems.2. Generators: Slip rings and carbon brushes are vital components in generating electricity in power plants, wind turbines, and hydroelectric installations. These devices utilize rotating magnetic fields, and slip rings play a significant role in transmitting the generated electrical energy to the grid through carbon brushes.3. Winding Systems: Slip rings and carbon brushes have proven essential in winding systems, such as transformers and coil winding machines. They enable the reliable transmission of electrical signals, ensuring effective control of the winding process and reducing the risk of malfunction.Maximizing Efficiency and Reliability:Proper maintenance and regular inspection of slip rings and carbon brushes are paramount to enhance efficiency and extend the lifespan of any electrical system. Periodic cleaning and replacing worn-out carbon brushes guarantee optimal performance while minimizing the risk of electrical failures and downtime. Neglecting these crucial maintenance steps can result in diminished connectivity, increased friction, and compromised safety.Conclusion:Slip rings and carbon brushes serve as the linchpin in the seamless transmission of electrical energy in numerous applications. Their ability to establish reliable electrical connections between stationary and rotating parts has revolutionized the functioning of electric motors, generators, and other intricate electrical systems. Understanding the importance of slip rings and carbon brushes helps industry professionals and enthusiasts alike appreciate the technological advancements brought by these key components, ensuring a more sustainable and efficient future.

Global Contactless Inductive Slip Ring Market: Insights, Trends, and Outlook to 2026

Contactless Inductive Slip Ring Market: Revolutionizing ConnectivityIn today's fast-paced world, where technology is advancing at an unprecedented rate, connectivity plays a vital role in various industries. Industries such as robotics, aerospace, and semiconductors rely heavily on seamless communication and data transfer. This is where contactless inductive slip rings come into play. The global contactless inductive slip ring market is experiencing significant growth, driven by innovations and advancements in the field of wireless power transmission.A slip ring, also known as a rotary electrical interface, is an electromechanical device that enables the transmission of power and signals between stationary and rotating components. Traditional slip rings rely on physical brushes or wires that can wear out over time, leading to performance degradation and maintenance issues. Contactless inductive slip rings, on the other hand, offer a revolutionary solution by eliminating the need for physical contact between the stationary and rotating parts.Inductive slip rings utilize electromagnetic coupling for power and signal transmission, enabling high-speed data transfer and power delivery without the concerns associated with traditional slip rings. By employing inductive coupling, these slip rings provide several advantages, including reduced friction, enhanced reliability, and increased lifespan. Moreover, contactless inductive slip rings ensure efficient power transmission, as there is no energy loss due to physical contact.The global contactless inductive slip ring market is witnessing robust growth due to the increasing need for reliable connectivity solutions in various industries. The rise in automation and the demand for efficient power and data transfer in robotics and industrial machinery are major drivers of market growth. Contactless inductive slip rings offer a compact and reliable solution for robotic arms, enabling seamless motion control and data exchange.Furthermore, the aerospace and defense sector is adopting contactless inductive slip rings for applications such as navigation systems, radar antennas, and communication systems. These slip rings ensure a reliable and continuous flow of power and signals, even in harsh environmental conditions. The ability of inductive slip rings to operate at high speeds and handle large amounts of data makes them ideal for aerospace applications.The semiconductor industry is another major consumer of contactless inductive slip rings. The continuous advancements in semiconductor technology, including wafer handling and testing, require highly reliable and high-speed connectivity solutions. Inductive slip rings provide a non-contact solution that minimizes signal interference and data loss, ensuring optimal performance in semiconductor manufacturing processes.In terms of geographical distribution, North America is expected to dominate the contactless inductive slip ring market. The region is home to several leading technology companies and is at the forefront of technological advancements. The automotive and aerospace industries in North America are expanding and demanding innovative connectivity solutions, further driving the market growth. Europe and Asia-Pacific are also witnessing significant growth, propelled by advancements in industrial automation and rapid industrialization.In conclusion, contactless inductive slip rings are revolutionizing connectivity in various industries by providing reliable and efficient power and signal transmission. These slip rings offer numerous advantages over traditional slip rings, including reduced friction, enhanced reliability, and increased lifespan. The global contactless inductive slip ring market is experiencing robust growth, driven by the increasing need for seamless and high-speed connectivity in industries such as robotics, aerospace, and semiconductors. As technology continues to evolve, contactless inductive slip rings will play a crucial role in enabling efficient and reliable communication and data transfer.

Advanced Slip Rings for Camera Systems: Embracing Seamless Rotational Movements

[Title]: New Camera Slip Ring Revolutionizes Panoramic Photography[Subheading]: Cutting-Edge Technology Transforms Photographic Equipment[News Content]:(Date), (City): A breakthrough innovation in the field of panoramic photography has been unveiled by technology company (remove brand name). The newly developed Camera Slip Ring promises to redefine the capabilities of photographic equipment, providing photographers and enthusiasts with unparalleled versatility in capturing panoramic images. This revolutionary product aims to revolutionize the way we document and appreciate the world around us.The Camera Slip Ring has been designed to address the challenges faced by photographers when attempting to capture panoramic shots. Existing solutions often suffer from limitations such as restricted range of motion, unreliable connections, and fixed rotation angles. These constraints have hindered professionals and amateurs alike from fully exploring the potential of panoramic photography. However, with the advent of the Camera Slip Ring, those constraints are being overcome, opening up a world of possibilities for image capture.According to (remove brand name) founder and CEO, (founder's name), the Camera Slip Ring is the result of years of research and development. The company's team of engineers and designers worked tirelessly to create a solution that would not only overcome existing limitations but also set new industry standards. With its compact design and cutting-edge technology, the Camera Slip Ring sets itself apart from its competitors.The Camera Slip Ring functions as an interface between the camera body and the lens, allowing smooth and continuous rotation of the camera while capturing panoramic shots. Its advanced mechanics ensure that photographers can seamlessly pan across wide vistas without interrupting the image capture process. Furthermore, the slip ring eliminates the need for cords and cables, providing a hassle-free experience for photographers on the move.The innovative design of the Camera Slip Ring also enables complete freedom of movement, granting photographers the ability to adjust the rotation speed and angle on the fly. This unprecedented flexibility allows for more creative control and ensures that photographers can capture panoramic images that are truly unique and visually striking.In addition to its impressive functionality, the Camera Slip Ring boasts exceptional durability and reliability. Constructed from high-quality materials, it is engineered to withstand the demanding conditions often encountered by photographers in the field. The slip ring's robust design ensures that it can handle prolonged use, making it an essential accessory for professionals and enthusiasts alike.To further enhance the user experience, (remove brand name) has integrated a user-friendly interface into the Camera Slip Ring. The interface allows photographers to customize their shooting preferences, adjust settings, and receive real-time feedback. With an intuitive and straightforward interface, even novices can quickly master the art of panoramic photography.The introduction of the Camera Slip Ring marks a significant milestone in the advancement of photographic equipment. By seamlessly blending cutting-edge technology with practical design, (remove brand name) has brought panoramic photography to new heights. With this revolutionary product, professional photographers can expand their artistic horizons, while enthusiasts can capture breathtaking landscapes and preserve memories like never before.As demand for panoramic photography continues to grow, the Camera Slip Ring holds vast potential. By enabling photographers to unleash their creativity without limitations, it is set to redefine the possibilities of image capture. With (remove brand name) leading the charge, we can expect a new era of stunning panoramic photographs that will transport us to breathtaking locations and evoke a sense of awe like never before.