Top Hybrid Slip Ring Suppliers: Providing High-Quality Products for Diverse Industries

By:Admin

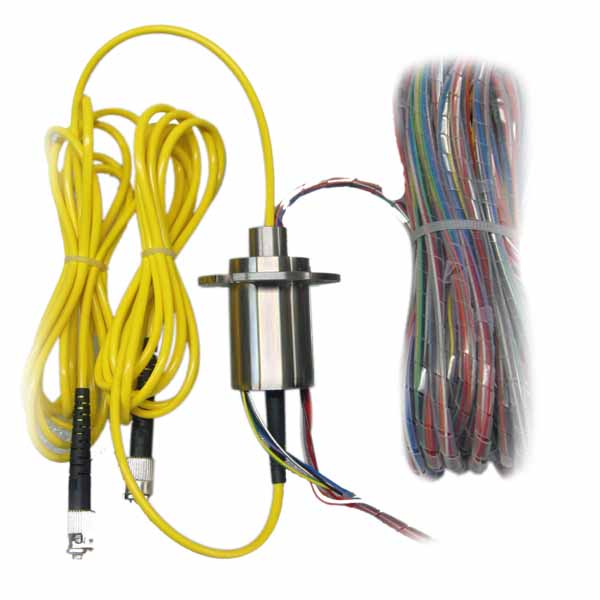

In today's fast-paced and technologically advanced world, efficient electrical connectivity is more important than ever. Industrial machinery, robotics, aerospace systems, and other high-tech applications rely heavily on the seamless transfer of power and data signals. A leading player in this field, Hybrid Slip Ring Supplier (name omitted), is making significant strides in providing cutting-edge solutions to meet the evolving needs of industries worldwide.

Hybrid Slip Ring Supplier, founded in 2005, has established itself as a reliable and trusted partner for businesses seeking specialized slip ring technology. With a strong commitment to innovation, the company has continuously developed and improved its hybrid slip rings, setting new industry standards.

The hybrid slip rings designed by Hybrid Slip Ring Supplier offer a unique combination of electrical power and data signal transmission capabilities. These slip rings enable uninterrupted rotation in electromechanical systems, allowing power and data to be transmitted between stationary and rotating components. This technology is crucial in applications where the continuous transmission of data and power is essential, such as wind turbines, packaging machinery, medical devices, surveillance systems, and more.

One of the key characteristics that sets Hybrid Slip Ring Supplier apart from its competitors is its emphasis on customization. The company understands that every industry and application can have unique requirements, making off-the-shelf solutions inadequate. To address this, Hybrid Slip Ring Supplier collaborates closely with its clients to provide tailored slip ring designs to meet their specific needs. Their team of experienced engineers adopts a customer-centric approach, ensuring that the final product not only meets the highest quality standards but also exceeds customer expectations.

With a strong focus on research and development (R&D), Hybrid Slip Ring Supplier consistently invests in cutting-edge technologies and manufacturing processes. By employing advanced techniques, such as precision machining, electrical testing, and multi-stage quality control, the company guarantees the reliability and longevity of its slip rings even in demanding environments. These stringent manufacturing protocols have earned it numerous certifications, including ISO 9001 and CE.

Furthermore, Hybrid Slip Ring Supplier recognizes the importance of continuous improvement and staying at the forefront of the industry. The company frequently collaborates with research institutions and partners worldwide to conduct joint development projects. This forward-thinking approach ensures that Hybrid Slip Ring Supplier's products remain innovative, adaptable, and capable of meeting emerging market demands.

In recent years, Hybrid Slip Ring Supplier has witnessed significant growth and expanded its presence globally. The company's products are now widely used across various industries, both domestically and internationally. Through a network of authorized distributors, Hybrid Slip Ring Supplier has successfully penetrated markets in North America, Europe, Asia-Pacific, and the Middle East, earning a solid reputation for its high-quality slip rings and impeccable customer service.

As industries continue to embrace automation, robotics, and advanced machinery, the demand for efficient electrical connectivity solutions is expected to soar. Hybrid Slip Ring Supplier remains committed to leading the way in this ever-evolving landscape, striving to provide innovative designs and exceptional service to customers worldwide.

In conclusion, Hybrid Slip Ring Supplier has established itself as a prominent player in the field of electrical connectivity solutions. Through its relentless commitment to innovation, customization, and quality, the company has earned the trust of numerous industries globally. As technology evolves and new challenges arise, Hybrid Slip Ring Supplier is well-positioned to continue driving advancements in slip ring technology, catering to the diverse needs of its customers while reaffirming its position as a leader in the market.

Company News & Blog

Advanced Flat Disk Slip Rings for Reliable Rotating Connections

Flat Disk Slip Rings Revolutionizing the Manufacturing IndustryIn recent news, a new type of slip ring has been developed that is set to revolutionize the manufacturing industry. The flat disk slip ring is a game-changing solution that is transforming the way power and signal is transmitted.Manufacturing companies depend heavily on machines to process raw materials and create finished products. These machines require a power source to operate, and often need to transmit signals to and from a control system. In order to accomplish this, slip rings have traditionally been used to transfer these signals and power from the rotating machine to the stationary control system.However, traditional slip rings have their limitations. They tend to be bulky, prone to wear and tear, and can suffer from signal degradation over time. Flat disk slip rings offer a new solution to these challenges. They are compact, durable, and provide reliable signal transmission.Flat disk slip rings have a unique design that eliminates the need for brushes. Instead, they use a rotating contact assembly that glides across a stationary conductive ring. This design helps to reduce the amount of friction and wear that occurs with traditional slip rings, making flat disk slip rings ideal for high-speed, continuous operation.The flat disk slip ring is an innovative solution that is already making a significant impact in the manufacturing industry. One company that has been at the forefront of this revolution is a leading provider of slip rings in the market. With years of experience in the field of slip ring technology, this renowned company has developed a range of flat disk slip rings that offer superior performance and reliability.These flat disk slip rings are manufactured using the latest technologies and materials to ensure the highest quality and durability. They offer a low-profile design that minimizes the overall size of the slip ring package, making them ideal for space-constrained applications. The slip rings are also available in a variety of different designs and materials, including stainless steel, aluminum, and brass.One of the key advantages of these flat disk slip rings is their ability to transmit a wide range of signals. They can transfer signals ranging from low voltage to high power, and from low frequency to high frequency. This makes them suitable for a wide range of applications, from small-scale laboratory equipment to large-scale industrial machinery.Another major advantage of these slip rings is their resistance to wear and tear. This is due to their unique design, which eliminates the need for brushes that can wear down over time. As a result, flat disk slip rings have a significantly longer lifespan than traditional slip rings.Overall, flat disk slip rings are a game-changing solution that is transforming the way power and signal is transmitted in the manufacturing industry. With their compact design, high reliability, and superior performance, they are an essential component for any company looking to improve its manufacturing processes. Companies that have implemented flat disk slip rings are already reaping the benefits of reduced downtime, improved productivity, and increased efficiency.

Reliable and Efficient Slip Rings for Power, Signal, and Data Transmission with Advanced Gigabit Ethernet Technology

Slip Rings: The Backbone of Reliable Power, Signal, and Data TransmissionIn today's fast-paced world, reliable transmission of power, signals, and data is vital to the functioning of various industries. This is where slip rings come into the picture. A slip ring is an electromechanical component that is used to transmit power, signals, and data from a stationary component to a rotating component. Slip rings have been around for over a century and have revolutionized the way power, signals, and data are transmitted.High Protection Slip Rings by Kbler GroupKbler Group is a company that has been manufacturing slip rings for more than 50 years. They specialize in the production of high-quality slip rings and other related components. Kbler Group's slip rings are renowned for their reliability and long service life. The company has recently launched a range of High Protection Slip Rings that are designed to withstand harsh environmental conditions and provide uninterrupted transmission of power, signals, and data.Features of High Protection Slip RingsThe High Protection Slip Rings by Kbler Group come with several features that make them a reliable choice for various industries. These slip rings are designed to offer high protection against dust, water, and chemicals. They come with an IP67 or IP68 protection rating, making them suitable for use in harsh outdoor environments.The Kbler slip rings also come with a modular design that makes them easy to install and maintain. The modular design also enables customization of the slip rings to specific requirements, making them suitable for a wide range of applications. These slip rings also come with Gigabit Ethernet transmission capabilities, making them ideal for data-intensive applications.Long Service LifeKbler Group's High Protection Slip Rings are designed to offer a long service life, even in harsh environmental conditions. The slip rings are made from high-quality materials that are designed to withstand extreme temperatures, shock, and vibration. The materials used are also resistant to wear and tear, ensuring long-lasting performance.Applications of High Protection Slip RingsThe High Protection Slip Rings by Kbler Group are suitable for use in various industries, including:1. Renewable Energy: High Protection Slip Rings are ideal for use in wind turbines and solar panels, where they are used to transmit power from the stationary component to the rotating component.2. Industrial Automation: Slip rings are used in various industrial automation applications, including packaging, printing, and robotics. High Protection Slip Rings are ideal for use in these applications, which often involve harsh environmental conditions.3. Medical Equipment: Slip rings are used in various medical equipment, including MRI machines and ultrasound machines. High Protection Slip Rings are suitable for use in these machines, where transmission of power and data is critical.ConclusionIn conclusion, slip rings are an essential component in the transmission of power, signals, and data. Kbler Group's High Protection Slip Rings are designed to offer high-performance, reliable transmission in harsh environmental conditions. Their modular design, long service life, and Gigabit Ethernet capabilities make them suitable for various industries, including renewable energy, industrial automation, and medical applications. If you're looking for a reliable slip ring for your application, consider Kbler Group's High Protection Slip Rings.

Top Hybrid Slip Ring Suppliers: Providing High-Quality Products for Diverse Industries

Hybrid Slip Ring Supplier Leads the Way in Electrical Connectivity SolutionsIn today's fast-paced and technologically advanced world, efficient electrical connectivity is more important than ever. Industrial machinery, robotics, aerospace systems, and other high-tech applications rely heavily on the seamless transfer of power and data signals. A leading player in this field, Hybrid Slip Ring Supplier (name omitted), is making significant strides in providing cutting-edge solutions to meet the evolving needs of industries worldwide.Hybrid Slip Ring Supplier, founded in 2005, has established itself as a reliable and trusted partner for businesses seeking specialized slip ring technology. With a strong commitment to innovation, the company has continuously developed and improved its hybrid slip rings, setting new industry standards.The hybrid slip rings designed by Hybrid Slip Ring Supplier offer a unique combination of electrical power and data signal transmission capabilities. These slip rings enable uninterrupted rotation in electromechanical systems, allowing power and data to be transmitted between stationary and rotating components. This technology is crucial in applications where the continuous transmission of data and power is essential, such as wind turbines, packaging machinery, medical devices, surveillance systems, and more.One of the key characteristics that sets Hybrid Slip Ring Supplier apart from its competitors is its emphasis on customization. The company understands that every industry and application can have unique requirements, making off-the-shelf solutions inadequate. To address this, Hybrid Slip Ring Supplier collaborates closely with its clients to provide tailored slip ring designs to meet their specific needs. Their team of experienced engineers adopts a customer-centric approach, ensuring that the final product not only meets the highest quality standards but also exceeds customer expectations.With a strong focus on research and development (R&D), Hybrid Slip Ring Supplier consistently invests in cutting-edge technologies and manufacturing processes. By employing advanced techniques, such as precision machining, electrical testing, and multi-stage quality control, the company guarantees the reliability and longevity of its slip rings even in demanding environments. These stringent manufacturing protocols have earned it numerous certifications, including ISO 9001 and CE.Furthermore, Hybrid Slip Ring Supplier recognizes the importance of continuous improvement and staying at the forefront of the industry. The company frequently collaborates with research institutions and partners worldwide to conduct joint development projects. This forward-thinking approach ensures that Hybrid Slip Ring Supplier's products remain innovative, adaptable, and capable of meeting emerging market demands.In recent years, Hybrid Slip Ring Supplier has witnessed significant growth and expanded its presence globally. The company's products are now widely used across various industries, both domestically and internationally. Through a network of authorized distributors, Hybrid Slip Ring Supplier has successfully penetrated markets in North America, Europe, Asia-Pacific, and the Middle East, earning a solid reputation for its high-quality slip rings and impeccable customer service.As industries continue to embrace automation, robotics, and advanced machinery, the demand for efficient electrical connectivity solutions is expected to soar. Hybrid Slip Ring Supplier remains committed to leading the way in this ever-evolving landscape, striving to provide innovative designs and exceptional service to customers worldwide.In conclusion, Hybrid Slip Ring Supplier has established itself as a prominent player in the field of electrical connectivity solutions. Through its relentless commitment to innovation, customization, and quality, the company has earned the trust of numerous industries globally. As technology evolves and new challenges arise, Hybrid Slip Ring Supplier is well-positioned to continue driving advancements in slip ring technology, catering to the diverse needs of its customers while reaffirming its position as a leader in the market.

Suppliers of Slip Rings and AC Drives to Three Phase Motors: Genuine Customer Reviews and Product Information

Optical Slip Rings Supplier Launches Range of Slip Rings and AC Drives [Location, Date] - As a leading supplier of optical slip rings, [Company Name], is pleased to announce the launch of its range of high-quality slip rings and AC drives designed to meet the demands of customers in industries such as marine, oil and gas, and automation.With over [Number] years of experience in the industry, [Company Name] has built a reputation for delivering high-quality products and services to customers worldwide. The range of slip rings and AC drives that the company provides covers a variety of applications, including wind turbines, servo motors, aerospace systems, and robotics, among others.The slip ring is an essential component that enables the transmission of electrical signals and power from a static platform to a rotating one. With [Company Name]'s extensive range of slip rings, customers can choose from different designs, including pancake slip rings, through-bore slip rings, and fiber optic slip rings, among others.Additionally, [Company Name] also offers a range of AC drives, which are necessary components in controlling the speed of three-phase motors that operate modern machines and equipment. These AC drives ensure precision control of the speed of three-phase motors. They are also energy-efficient and reliable, ensuring that businesses are not only environmentally friendly, but they also experience cost savings.[Company Name]'s range of products is designed with the customer in mind, providing innovative solutions that meet the specific needs of different industries. The products offered by the company are manufactured using state-of-the-art technology and high-quality materials, ensuring that they are durable and reliable.As part of [Company Name]'s commitment to providing excellent customer service, the company's website provides genuine customer reviews of their products and services, allowing potential customers to make informed buying decisions. The website also provides detailed product and service information for the convenience of customers."Our range of slip rings and AC drives is designed to provide innovative solutions to meet the unique needs of our customers. We understand the importance of reliability and durability in the industries we serve, and that's why our products are manufactured using the latest technology and high-quality materials. We are committed to providing excellent customer service and ensuring that our customers receive products that meet their expectations," said [Person Name], spokesperson for [Company Name].In conclusion, [Company Name]'s range of slip rings and AC drives are essential components in the operation of modern machines and equipment, providing reliable solutions to meet the specific needs of different industries. With several years of experience in the industry, [Company Name] is a trusted supplier of high-quality products and services to customers worldwide. To learn more about the range of products and services offered by the company, visit their website.

Unleashing the Potential of Slip Rings: A Revolutionary Solution for Enhanced Propeller Performance

Propeller Slip Rings: The Ultimate Solution for Efficient and Reliable Power Transfer in Marine ApplicationsIn the world of marine engineering, reliable and efficient power transfer is of utmost importance. Whether it’s for steering, propulsion, communication, or other critical functions, any interruptions or failures in power transfer can lead to disastrous consequences. This is where propeller slip rings (PSRs) come into play. These specialized electrical connectors provide a continuous and reliable electrical connection between the rotating and stationary parts of a marine propulsion system, ensuring smooth power transfer without any loss or interruption.The propeller slip ring is essentially a device that enables the transfer of power and signals from a stationary part to a rotating part without the need for complex and bulky wiring. The device comprises a stationary brush block and a rotating collector ring, separated by a set of brushes that maintain contact and transmit power and signals between the two parts. The brushes are made of high-quality materials and are designed to withstand the harsh marine environment, including saltwater corrosion, vibration, and extreme temperatures.Propeller slip rings have become indispensable components of marine propulsion systems, especially in ships and boats that rely on electric or hybrid power. These systems require a continuous and efficient flow of electrical power to drive the motor and turn the propeller, as well as maintain other essential functions like navigation, lighting, and communication. Propeller slip rings ensure that the power transfer is seamless and reliable, thereby reducing downtime and maintenance costs.One of the leading manufacturers of propeller slip rings is a global supplier of high-performance electrical solutions for a wide range of industries, including marine, oil and gas, wind power, and aerospace. The company has been providing cutting-edge slip ring technology for over two decades, catering to the evolving needs of the marine industry. With a strong focus on innovation and quality, the company has earned a reputation as a trusted partner for marine OEMs and operators around the world.The company’s propeller slip rings are designed to meet the highest standards of durability, efficiency, and safety. The slip rings are engineered to withstand extreme environments and heavy loads, ensuring a long service life and minimal maintenance requirements. The devices are also customizable, allowing the company to tailor the slip ring solutions to the specific needs of each customer. This flexibility and agility have been crucial in staying ahead of the competition and meeting the ever-changing demands of the marine market.The propeller slip rings from the company are available in various sizes, configurations, and materials to suit different marine applications. The slip rings can accommodate a wide range of electrical currents and voltages, from low-power signals to high-power propulsion systems. The devices are also compatible with different types of connectors and cables, making them easy to integrate into existing marine systems.One of the key advantages of propeller slip rings is their ability to reduce friction and wear in rotating machinery. The slip rings eliminate the need for trailing wires or cables that can get tangled or damaged, leading to downtime and costly repairs. With slip rings, the electrical connection is fixed and stable, allowing the machinery to operate smoothly and efficiently. This leads to lower energy consumption, reduced emissions, and improved overall performance.Another advantage of propeller slip rings is their safety and reliability. The devices are designed to meet the strictest safety standards, including ATEX and IECEx certifications for explosive environments. They are also tested and validated for high shock and vibration resistance, ensuring that they can withstand the toughest conditions at sea. This reliability is critical for maintaining the safety and integrity of the marine vessel and crew.In conclusion, propeller slip rings are essential components of modern marine propulsion systems, providing a reliable and efficient electrical connection between the stationary and rotating parts. With their durability, flexibility, and safety features, slip rings are helping marine operators around the world reduce downtime, increase efficiency, and improve overall performance. The company’s propeller slip rings are at the forefront of this technology, providing customized and cutting-edge solutions for the ever-evolving needs of the marine industry.

High-Quality Slip Ring ZSR-24-2 Manufacturers & Suppliers in China

Slip Ring Connector Suppliers: Leading the Way in AdvancementTechnology never ceases to amaze us. With the constant influx of new gadgets and gizmos being introduced in the market, creating connections between machines have become increasingly important. The use of slip rings is one such technology that has revolutionized the way machines operate applications and processes. Slip ring connectors are electrical connectors that allow the transmission of power and signals from a stationary point to a rotating point. It is an indispensable component for a lot of industrial equipment that requires continuous contact between electronic and mechanical systems. As a result, the demand for slip ring connector suppliers has increased to address the growing need for this technology.Understanding Slip RingsSlip rings operate through the principles of electromechanical devices. It is a rotating component that transfers electrical current from a static source to a rotating entrance. It is composed of an assembly of metal rings that are arranged in such a manner to enable current transmission. Each ring is insulated from one another by a non-conductive material. Metal brushes or sliding contacts are then employed to transmit the electrical current from the stationary source to the moving components in the system. Slip rings have evolved over time and today, they come in different types such as through bore slip rings, capsule slip rings, and pancake slip rings.Applications of Slip Ring ConnectorsSlip rings operate in environments where there is a need for continuous rotation in electrical and mechanical systems while maintaining the integrity of data and specifications. It is largely used in applications that require data and power transfer, torque and position sensing, and data acquisition. Slip rings are used in a variety of industries such as aviation, military equipment, medical equipment, railways, robotics, wind turbines, packaging machinery and amusement park rides. Each application has unique requirements, and as such certain specifications such as operating temperatures, speed, and electrical parameters must be taken into consideration.Choosing the Right Slip Ring Connector SupplierThere are numerous connector suppliers in the market who provide different types of slip rings. When choosing a slip ring connector supplier, it is important to consider factors like product quality, delivery time, pricing, and customer service. A reliable supplier will provide support throughout the process, from technical support during the design phase to after-sale support. They should also provide documentation and testing to ensure the slip rings are compliant with industry standards.ConclusionSlip ring connectors have become a critical component of modern machinery. As a result, selecting the right slip ring connector supplier that provides reliable products and exceptional service is crucial to ensure success in your application. Today, with technological advancements, slip ring connectors have become more advanced, more efficient, and more reliable. Don't settle for less and choose a reliable slip ring connector supplier that leads the way in advancement towards a better tomorrow.

Contactless Inductive Slip Ring Market Analysis, Trends, and Forecast 2026: Insights and Insights for Global and China Markets

Contactless Inductive Slip Ring Market Insights: The Future of Slip Ring Manufacturing in TurkeySlip rings are critical components in electromechanical systems that require power and signal transmissions between rotating and stationary elements. In the past, conventional slip rings used brushes to make electrical contact, which posed problems such as wear, friction, and maintenance issues. Today, contactless inductive slip rings represent the latest technological breakthrough in slip ring manufacturing. According to the recent report by QYResearch Group, the global and China contactless inductive slip ring market is projected to grow steadily over the next few years, opening up new opportunities for slip ring manufacturers in Turkey.Segmentation by GeographyThe report indicates that the contactless inductive slip ring market is segmented by region (country), with the largest market share in China and Europe. However, the market is expected to grow rapidly in developing countries such as Turkey, where the demand for advanced slip ring technologies is on the rise.Contactless Inductive Slip Ring TechnologyContactless inductive slip rings are based on the principle of electromagnetic induction, which eliminates the need for brushes and increases the reliability and lifespan of slip rings. Inductive slip rings have become increasingly popular in industrial applications such as energy, aerospace, defense, and robotics, where the rotating machinery needs to transfer power and signal without interruption.Benefits of Inductive Slip RingsCompared to conventional slip rings, contactless inductive slip rings offer several advantages, including:1. Reduced Wear: Inductive slip rings have fewer parts in contact, which leads to less wear and tear on the components.2. Low Maintenance: Inductive slip rings require little to no maintenance, which reduces downtime and repair costs.3. High Reliability: Inductive slip rings provide reliable power and signal transfer, with no interruptions or signal loss.4. High-Speed Rotation: Inductive slip rings can support high-speed rotation, making them ideal for demanding applications.5. Compact Size: Inductive slip rings can be designed to be compact in size, which saves space and weight in the system.Opportunities for Slip Ring Manufacturers in TurkeyAs a rapidly developing market, Turkey offers many opportunities for slip ring manufacturers to expand their businesses. With the growing demand for advanced slip ring technologies in various industries, Turkish manufacturers can take advantage of the latest trends and innovations in slip ring manufacturing. In addition, Turkey's strategic location between Europe, Asia, and the Middle East makes it an ideal hub for exporting slip rings to neighboring countries.ConclusionWith the growing demand for advanced slip ring technologies, manufacturers in Turkey can capitalize on the latest trends and innovations in slip ring manufacturing. The shift towards contactless inductive slip rings offers many benefits over conventional slip rings, such as reduced wear, low maintenance, high reliability, high-speed rotation, and compact size. As the demand for slip rings increases in various industries, Turkish manufacturers can become key players in the global slip ring market. Keywords: Slip Ring Manufacturer Turkey.

High-Quality Slip Ring of Single-Channel High Frequency Rotary Joint with Small Size for Precise Instrument: A Chinese Product

Gimbal Small Size Slip Rings: Offering High-Quality Slip Ring of Single-Channel High-Frequency Rotary Joint with Small Size for Precise InstrumentsIn the world of precision instruments, having reliable and efficient rotary joints is of utmost importance. These rotary joints play a crucial role in transmitting signals and power between the stationary and rotating parts of various devices such as gimbals, drones, cameras, and robotic arms. A slip ring is one such rotary joint that has gained significant attention due to its ability to transmit signals and power continuously while rotating.China, being a global manufacturing hub, has emerged as a leading player in slip ring production. Among the many manufacturers, there is one company that stands out for its commitment to producing high-quality slip rings – Gimbal Small Size Slip Rings.Gimbal Small Size Slip Rings is a renowned name in the slip ring industry, known for its focus on precision and reliability. Their latest offering, the Slip Ring of Single-Channel High-Frequency Rotary Joint with Small Size for Precise Instruments, has garnered attention for its superior performance and compact design.The slip ring is designed keeping in mind the requirements of precise instruments. With a single-channel high-frequency rotary joint, it enables the transmission of signals at high frequencies without compromising on quality. This makes it ideal for devices that demand quick and accurate data transmission, such as robotic control systems and high-speed cameras.One of the standout features of the slip ring is its small size. Gimbal Small Size Slip Rings understands the importance of space-saving designs, especially in compact instruments and gadgets. The compact size of this slip ring allows for easy integration into devices without adding unnecessary bulk or hindering their functionality. This opens up new possibilities for miniaturization in various industries, where space optimization is crucial.Strict quality control is an integral part of Gimbal Small Size Slip Rings' manufacturing process. They are committed to delivering slip rings that meet the highest industry standards. Their slip rings undergo rigorous testing and quality checks, ensuring consistent and reliable performance. With years of experience and advanced manufacturing techniques, Gimbal Small Size Slip Rings has earned a reputation for producing slip rings that are robust, durable, and long-lasting.The slip rings offered by Gimbal Small Size Slip Rings also boast efficient power transmission capabilities. With low electrical noise and minimal voltage drop, these slip rings ensure smooth and uninterrupted power supply to connected devices. This is particularly important in instruments that rely on precise power delivery, as any fluctuations or interruptions in power can result in inaccurate readings or system failures.Gimbal Small Size Slip Rings' slip rings are also highly versatile. They can be customized to meet specific requirements, including different signal channels, frequency ranges, and power ratings. This flexibility allows for seamless integration into a wide range of instruments, making them suitable for various applications in industries such as aerospace, defense, automation, and medical.In conclusion, Gimbal Small Size Slip Rings has proven itself as a leading manufacturer of high-quality slip rings. Their Slip Ring of Single-Channel High-Frequency Rotary Joint with Small Size for Precise Instruments stands out for its compact design, excellent signal transmission capabilities, and strict adherence to quality standards. As the demand for precise instruments continues to grow, having reliable slip rings like those offered by Gimbal Small Size Slip Rings will be crucial for ensuring accurate and efficient performance.

Title: Revolutionizing Power Transmission: The Versatility of Slip Rings for AlternatorsIntroduction (approx. 100 words):Welcome to the fascinating world of slip rings, where electrical connections thrive even while components rotate. In this blog post, we delve into the intricacies of slip rings, focusing particularly on their pivotal role in enhancing the efficiency and convenience of alternators. We'll explore the basics of slip rings, their construction, and shed light on their various applications. So, get ready to unravel the secrets behind slip rings and why they are crucial for alternators!1. Understanding Slip Rings and their Functionality (approx. 200 words):Slip rings, also called rotating electrical connectors, play a significant role in transmitting power and electrical signals between stationary and rotating parts of a system. Traditional methods of power transmission involved the use of wires that would become tangled when components rotate. Slip rings revolutionize this process by providing a seamless solution that allows continuous power flow.At the core of slip rings lie two essential components: a stationary ring that receives power from an AC/DC power source, and a rotating ring which facilitates the electrical connection points. By maintaining a constant electrical connection, slip rings eliminate the need for unreliable wired connections and enable smooth rotation without interruption.2. The Anatomy of Slip Rings (approx. 300 words):To ensure optimal performance, slip rings are meticulously designed and constructed. The stationary rings consist of high-quality conductive materials that transmit a steady power supply. On the other hand, the rotating rings, which are in constant motion, are designed with multiple connecting points to accommodate various electrical requirements.To offer flexibility, slip rings can be customized to fit specific needs. The number of connecting points can range from two to four, providing exceptional versatility for different applications. Additionally, slip rings are precision-engineered to withstand high speeds, temperature variations, and other environmental factors, thus ensuring long-lasting and reliable performance.3. Slip Rings and their Role in Alternators (approx. 300 words):Alternators, an essential component of electrical power systems, often require slip rings for efficient functioning. These devices enable the transmission of electricity from the rotating alternator shaft to the outside electrical circuit.The slip ring assembly within an alternator helps maintain the stationary field coil connection while enabling continuous electrical flow to the rotating rotor. By utilizing slip rings, alternators can generate electrical power without any interruption in the rotation, ensuring a stable power supply.Moreover, slip rings enhance the overall efficiency of alternators by minimizing energy losses during power transmission. This increased efficiency translates into reduced wear and tear of the system, thereby prolonging the lifespan of the alternator.4. Wide Range of Applications (approx. 200 words):Apart from alternators, slip rings find extensive use across diverse industries. They prove invaluable in wind turbines, industrial machinery, robotics, medical equipment, CCTV systems, and many more applications. Slip rings enable the seamless transfer of power and signals, making them an essential component in any rotating system.Conclusion (approx. 100 words):In conclusion, slip rings act as indispensably reliable rotating connectors, ensuring the efficient flow of electricity in rotating systems. In the context of alternators, slip rings play a vital role in maintaining a steady power supply without compromising the integrity of the rotation. From their basic construction to their versatile applications, slip rings revolutionize power transmission. As technology continues to evolve, slip rings will undoubtedly remain at the forefront, ensuring smooth electrical connectivity and improved efficiency in a wide range of applications.

Hollow Slip Ring: Ideal Solution for Transmitting Power and Signals in Rotating Devices

Title: Senring Electronics Introduces the Versatile H Series Through Hole Slip Rings for Seamless Power and Signal TransmissionIntroduction:Senring Electronics Co., Ltd., a leading manufacturer of slip rings, is proud to present their latest innovation, the H Series Through Hole Slip Rings. Also known as hollow slip rings with a center hole, this advanced technology offers seamless power and signal transmission for devices requiring 360-degree rotation. With its superior design and functionality, Senring H series through hole slip rings are set to revolutionize various industries, offering unparalleled performance and reliability.Power and Signal Transmission Made Easy:The H Series Through Hole Slip Rings by Senring Electronics provide an efficient solution for devices that require both power and signal transmission during continuous rotation. These slip rings are ideal for applications such as wind turbines, robotics, packaging machinery, medical equipment, and many more.Superior Design Features:1. Hollow Center Hole: The hollow design of these slip rings allows for the integration of existing equipment components while seamlessly transmitting power and signals. This central opening also enables easy passage for fluid, gases, or other necessary connections.2. High-Speed and Low-Noise Transmission: Senring H series slip rings are designed to transmit sensitive signals with minimal loss and interference. They ensure high-speed and low-noise data transmission, making them suitable for demanding industries such as automation, aerospace, and defense.3. Modular Design: The modular structure of the H series slip rings offers flexibility regarding customization and adaptability to various applications. It allows for easy installation, maintenance, and upgrades, reducing downtime and improving efficiency.4. Large Current and Voltage Capacity: These slip rings can handle substantial electrical loads, making them suitable for applications requiring high current and voltage requirements. With reliable insulation and advanced technology, Senring slip rings ensure safe and efficient power transmission, minimizing the risk of electrical failures.Benefits and Applications:1. Wind Turbines: The H Series Through Hole Slip Rings are crucial for transferring power and signals for yaw systems, pitch control systems, and turbine blades that require continuous rotation. Senring slip rings ensure consistent energy production, reduced maintenance, and increased durability.2. Robotics: In applications such as robotic arms and automated assembly lines, the H series slip rings facilitate seamless power transmission and control signal exchange, enabling uninterrupted and precise movements.3. Medical Equipment: Hollow slip rings are widely used in medical devices such as computerized tomography (CT) scanners and magnetic resonance imaging (MRI) machines, where the ability to rotate continuously without compromising signal integrity is essential.4. Packaging Machinery: These slip rings enhance the performance of packaging machinery by allowing electrical signal and power transmission for rotating parts. This enables consistent operation and ensures the seamless wrapping, sealing, and labeling of products.Conclusion:Senring Electronics Co., Ltd.'s H Series Through Hole Slip Rings offer a groundbreaking solution for seamless power and signal transmission in applications requiring 360-degree rotation. With their hollow design, high-speed transmission capabilities, and modular structure, these slip rings provide reliable and efficient performance across various industries. Senring's commitment to innovation and dedication to meeting customer requirements make them an industry leader in slip ring technology.