Ultimate Guide to Sliding Contact Slip Rings: What You Need to Know

By:Admin

The company behind this groundbreaking technology has been at the forefront of slip ring manufacturing for over two decades. With a strong focus on research and development, the company has consistently pushed the boundaries of what is possible in slip ring design and functionality. This commitment to innovation and excellence has earned the company a reputation as a trusted provider of high-quality slip rings for a diverse customer base.

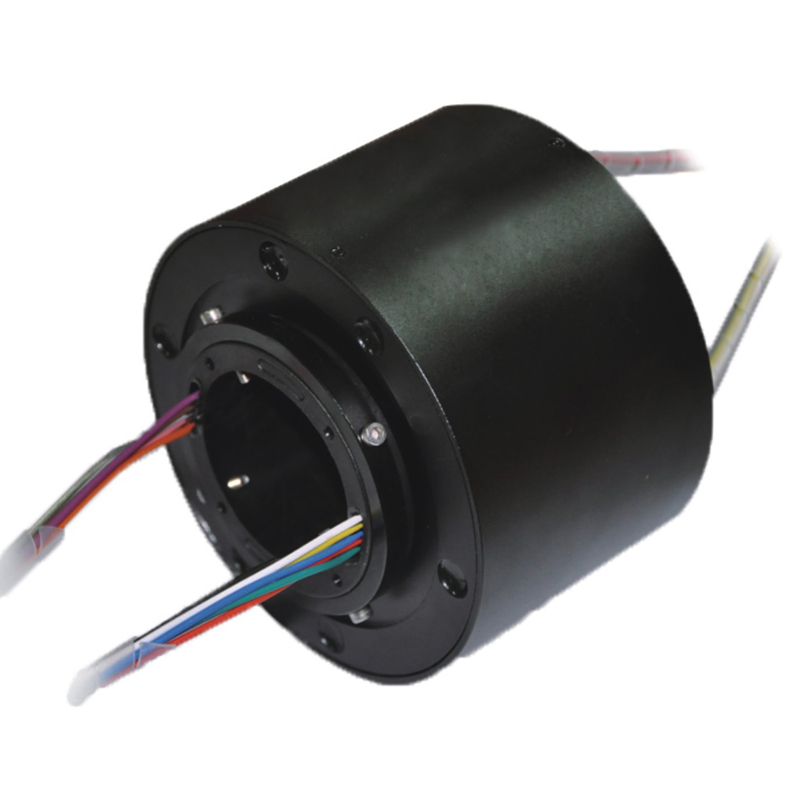

The Sliding Contact Slip Ring is a testament to the company's dedication to meeting the evolving needs of its customers. Unlike traditional slip rings, which rely on brushes and rings to transfer power and signals, the sliding contact slip ring utilizes a unique sliding contact technology. This allows for a smooth and continuous transfer of power and signals, minimizing wear and tear and ensuring long-term reliability. In addition, the sliding contact design eliminates the need for maintenance, making it ideal for applications where regular maintenance is difficult or impractical.

One of the key advantages of the Sliding Contact Slip Ring is its ability to handle high-speed and high-frequency data transmission. This makes it an ideal solution for applications such as robotics, automation, and data communication systems, where fast and reliable data transfer is essential. The slip ring's low electrical noise and interference further enhance its suitability for these applications, ensuring the integrity of the transmitted signals.

Another notable feature of the Sliding Contact Slip Ring is its robust construction, which allows it to operate in harsh environmental conditions. Whether it is exposed to extreme temperatures, moisture, or dust, this slip ring is designed to withstand the challenges of demanding industrial environments. This makes it a reliable and durable solution for a wide range of applications, including aerospace, marine, and industrial machinery.

In the field of medical devices, the Sliding Contact Slip Ring offers significant advantages. Its compact and lightweight design makes it well-suited for integration into medical equipment, where space is often limited. Furthermore, the slip ring's reliable performance and low maintenance requirements make it an ideal choice for critical medical applications, where downtime must be minimized.

As the demand for renewable energy sources continues to grow, the Sliding Contact Slip Ring has found a niche in the wind energy industry. Its ability to transmit power and signals in wind turbines, where continuous rotation and varying environmental conditions are common, has made it a preferred solution for wind turbine manufacturers and operators. The slip ring's ability to handle high currents and voltages, combined with its long-term reliability, makes it an essential component in the efficient operation of wind turbines.

With its groundbreaking technology and diverse applications, the Sliding Contact Slip Ring is a testament to the company's commitment to innovation and excellence. As the demand for reliable and efficient power and data transmission solutions continues to grow, this slip ring is poised to play a key role in a wide range of industries. With a track record of delivering high-quality slip rings and a passion for pushing the boundaries of what is possible, the company is well-positioned to continue leading the way in slip ring technology.

Company News & Blog

High-Quality Slip Ring Manufacturer in China - Latest News

China Slip Ring Company is a leading manufacturer of high-quality slip rings and rotary joints for various industries. With their extensive experience and advanced technology, the company has been providing reliable and efficient solutions for transmitting power and data in rotating machinery for over a decade.The company's comprehensive product line includes standard slip rings, custom-designed slip rings, and rotary joints that are suitable for a wide range of applications, including aerospace, defense, medical equipment, packaging machinery, and more. Their products are known for their high performance, long service life, and robust design, making them the ideal choice for demanding industrial environments.In addition to their standard products, China Slip Ring Company also offers custom solutions to meet specific customer requirements. Their team of experienced engineers and technicians work closely with clients to develop tailored slip ring and rotary joint solutions that perfectly fit their needs. Whether it's a complex integration project or a simple modification, the company is committed to delivering innovative and reliable products that exceed customer expectations.With a strong focus on research and development, China Slip Ring Company continuously strives to improve their products and explore new technologies. Their state-of-the-art manufacturing facilities and strict quality control processes ensure that every product meets the highest standards of performance and reliability. This dedication to excellence has earned the company a reputation as a trusted and preferred supplier in the industry.In addition to their product excellence, China Slip Ring Company places great emphasis on customer satisfaction and after-sales support. Their knowledgeable sales team and technical experts provide professional advice and assistance to help clients find the best solutions for their applications. Moreover, the company offers comprehensive technical documentation, installation guides, and maintenance services to ensure seamless integration and trouble-free operation of their products.Furthermore, China Slip Ring Company is committed to sustainability and environmental responsibility. They adhere to strict environmental regulations and standards in their manufacturing processes, and constantly seek ways to minimize their ecological footprint. By using recyclable materials, reducing energy consumption, and implementing eco-friendly practices, the company aims to contribute to a cleaner and greener world.As China Slip Ring Company continues to expand its presence in the global market, they remain dedicated to upholding their core values of innovation, quality, and customer satisfaction. Their relentless pursuit of excellence and commitment to delivering reliable products have earned them the trust and confidence of their customers worldwide.In conclusion, China Slip Ring Company's extensive product range, custom solutions, commitment to innovation, and dedication to customer satisfaction make them a reliable and preferred partner for slip rings and rotary joints. With their unwavering focus on quality and continuous improvement, the company is well positioned to meet the evolving needs of various industries and maintain their leadership in the market.

High-Quality Compact Slip Ring for Smooth Electrical Connections

Compact Slip Ring Revolutionizes Data Transmission for Industrial ApplicationsIn today's fast-paced industrial environment, the need for efficient and reliable data transmission has become increasingly crucial. A reliable slip ring is essential for the smooth transmission of signals, power, and data between stationary and rotating components in various industrial applications. The introduction of the Compact Slip Ring (CSR) by a leading manufacturer has revolutionized data transmission in industrial settings, offering a compact, high-performance solution to meet the growing demands of modern automation and control systems.The CSR is designed to meet the challenges of modern industrial applications, offering a seamless and reliable connection for a wide range of signals and power requirements. With its compact design and advanced technology, the CSR provides a reliable solution for transmitting data and power in applications where space is limited and performance is critical.One of the key features of the CSR is its compact size, which allows for easy integration into tight spaces without compromising performance. This makes it an ideal solution for a wide range of applications, including robotics, medical devices, packaging machinery, and more. The CSR's ability to transmit high-speed data and power with minimal interference makes it a valuable asset in modern industrial systems, where precision and reliability are paramount.Furthermore, the CSR is designed to meet the rigorous demands of industrial environments, with a durable construction that ensures reliable performance in harsh operating conditions. Its robust design and high-quality materials make it resistant to shock, vibration, and extreme temperatures, providing a dependable solution for a wide range of industrial applications.The advanced technology featured in the CSR sets it apart from traditional slip rings, offering enhanced performance and reliability for modern industrial systems. With its low contact resistance and high-speed data transmission capabilities, the CSR provides a reliable solution for demanding industrial applications where signal integrity and data accuracy are crucial.The CSR is also designed to be maintenance-free, reducing downtime and ensuring continuous operation in industrial environments. This is made possible by the use of advanced materials and precision engineering, which result in a slip ring that requires minimal maintenance and delivers long-term reliability.As a leading manufacturer of slip rings, the company behind the CSR has a proven track record of delivering innovative solutions for industrial applications. With a focus on quality, reliability, and performance, the company is committed to meeting the evolving needs of modern industrial systems and providing cutting-edge solutions that enable customers to achieve their goals efficiently and effectively.The introduction of the Compact Slip Ring represents a significant advancement in data transmission technology for industrial applications, offering a compact, high-performance solution that meets the demands of modern automation and control systems. With its advanced technology, durable construction, and maintenance-free design, the CSR is poised to make a lasting impact on the industrial sector, providing a reliable and efficient solution for transmitting data and power in a wide range of applications.In conclusion, the Compact Slip Ring represents a significant leap forward in data transmission technology for industrial applications. With its compact size, advanced technology, and robust construction, the CSR offers a reliable and efficient solution for transmitting data and power in modern industrial systems, setting a new standard for performance and reliability in the industry.

Key Features of Sliprings for Industrial Robots

Industrial Robot Slipring: A Revolutionary Component in RoboticsThe use of industrial robots has revolutionized many industries, from manufacturing and automotive to healthcare and entertainment. These robots are designed to operate in various environments and perform complicated tasks with precision and efficiency. One crucial component that enables these robots to function seamlessly is the slipring, a vital connection point that allows for the transfer of power and data between the robot arm and the fixed structure. One company that is leading the way in the development and production of industrial robot sliprings is [Company Name].[Company Name] is a renowned manufacturer of high-quality sliprings for industrial robots. With years of experience and expertise in the field, [Company Name] has established itself as a trusted partner for many robotics companies around the world. Their sliprings are known for their reliability, durability, and advanced technology, making them indispensable components in modern industrial robots.The [Company Name] industrial robot slipring is designed to meet the rigorous demands of robotic applications. It is capable of transmitting power and data signals with minimal interference, ensuring smooth and precise operation of the robot arm. The slipring is also built to withstand harsh industrial environments, with protection against dust, moisture, and vibration, making it suitable for a wide range of robotic applications.One of the key features of the [Company Name] industrial robot slipring is its modular design, which allows for easy installation and maintenance. This modular approach also enables customization to meet specific requirements, such as the number of channels, signal types, and mounting options, giving robotics companies the flexibility to tailor the slipring to their unique needs.In addition to its technical capabilities, the [Company Name] industrial robot slipring is backed by a dedicated team of engineering and technical support professionals who are committed to providing expert guidance and assistance to customers. Whether it's designing a custom solution or troubleshooting a technical issue, [Company Name] is known for its responsive and reliable customer service.The adoption of industrial robot sliprings has become increasingly important as the demand for robotics continues to grow across various industries. These sliprings play a critical role in enabling robots to perform a wide range of tasks, from assembly and welding to material handling and inspection, with precision and efficiency. As robotics technology advances and robots are deployed in more complex and dynamic manufacturing environments, the need for reliable and high-performance sliprings becomes even more crucial.With its commitment to innovation and quality, [Company Name] is well positioned to meet the evolving demands of the robotics industry. The company continuously invests in research and development to enhance its slipring technology and expand its product offerings to address the changing needs of robotics applications. This proactive approach ensures that [Company Name] remains at the forefront of the industry, delivering cutting-edge solutions to its customers.As the global market for industrial robots continues to grow, the role of sliprings in enabling their performance will become even more significant. [Company Name] is dedicated to providing robust and reliable slipring solutions that will empower the next generation of industrial robots to achieve new levels of productivity and versatility.In conclusion, the industrial robot slipring is a critical component in enabling the seamless operation of industrial robots in various applications. With its advanced technology, durability, and dedicated customer support, [Company Name] has established itself as a leading provider of high-quality sliprings for robotics. As the robotics industry continues to evolve, [Company Name] remains committed to driving innovation and delivering exceptional solutions to meet the growing demands of industrial robot applications.

High-Quality USB Slip Ring for Reliable Data Transfer

Company Introduction: Our company is a leading manufacturer and supplier of high-quality electrical and mechanical components for a wide range of industries. With over 20 years of experience in the industry, we have built a strong reputation for providing superior products and excellent customer service. Our dedicated team of engineers and technicians are committed to innovation and quality, ensuring that our products meet the highest standards of performance and reliability.News Content: Usb Slip Ring: A Breakthrough in Data Transmission TechnologyIn today's fast-paced world, the demand for high-speed and reliable data transmission is greater than ever before. Industries such as robotics, automation, and telecommunications rely heavily on the seamless transfer of data, and any disruption in this process can result in significant downtime and loss of productivity. This is where the groundbreaking technology of the USB slip ring comes into play, offering a solution to the challenges of data transmission in rotating or moving applications.The USB slip ring is a revolutionary product that enables the transfer of data between a stationary and rotating structure without the need for cables, allowing for continuous and uninterrupted communication. This is achieved through a series of electrical and mechanical components that are designed to maintain a stable connection even when the devices are in motion. With the ability to transmit both power and data, the USB slip ring is a versatile solution that can be utilized in a wide range of applications."Our USB slip ring is a game-changer in the field of data transmission technology," said a spokesperson for our company. "We have invested heavily in research and development to create a product that meets the growing needs of modern industries. With its high-speed capabilities and robust design, the USB slip ring is poised to revolutionize the way data is transmitted in rotating or moving applications."The USB slip ring is designed to meet the highest standards of performance and reliability, making it suitable for mission-critical applications where continuous data transmission is essential. Its compact size and lightweight construction make it easy to integrate into existing systems, providing a seamless solution for companies looking to improve their data transmission capabilities.In addition to its technical capabilities, the USB slip ring also offers cost-saving benefits by eliminating the need for complex cable management systems. This not only reduces installation time and maintenance costs but also minimizes the risk of cable damage and signal interference.As industries continue to embrace automation and digitalization, the demand for advanced data transmission solutions will only continue to grow. The USB slip ring represents a significant advancement in this field, offering a reliable and efficient solution for the challenges of data transmission in rotating or moving applications.With our company's commitment to innovation and quality, the USB slip ring is set to become a leading product in the market, providing companies with the means to improve their data transmission capabilities and drive their businesses forward. As we look to the future, we are confident that the USB slip ring will play a pivotal role in shaping the next generation of data transmission technology.

Guide to Understanding Anchor Slip Rings and Their Uses

Anchor slip rings are essential components in various industrial applications, providing a reliable and efficient means of transmitting power and electrical signals between stationary and rotating components. With the increasing demand for high-quality slip rings in a wide range of industries, the market for these products has continued to grow steadily. One company that has been at the forefront of this industry is {}. {} is a leading manufacturer of slip rings, specializing in the design and production of high-performance anchor slip rings for a diverse range of applications. With a focus on quality, innovation, and customer satisfaction, the company has established itself as a trusted provider of slip ring solutions to clients around the world.The anchor slip rings produced by {} are designed to meet the specific requirements of each customer, with a focus on durability, reliability, and performance. The company’s extensive experience in slip ring technology, combined with a commitment to research and development, ensures that its products are at the cutting edge of the industry.One of the key features of {}'s anchor slip rings is their ability to operate in challenging environments, including high temperatures, corrosive substances, and other harsh conditions. This makes them well-suited for use in a wide range of industries, including robotics, wind turbines, medical devices, and more. In addition to their standard product line, {} also offers custom-designed anchor slip rings to meet the unique needs of specific applications. This flexibility and attention to customer requirements set {} apart from other slip ring manufacturers, making them a preferred choice among clients with specialized needs.With an unwavering commitment to quality, {} has implemented rigorous quality control measures at every stage of the production process. This ensures that each anchor slip ring that leaves their facility meets the highest standards of performance and reliability. As a result, customers can be confident in the durability and longevity of {}’s products.Furthermore, {} places a strong emphasis on customer service and support, with a dedicated team of professionals who are available to provide technical assistance, answer questions, and offer guidance throughout the purchasing process. This commitment to customer satisfaction has earned {} a reputation for excellence within the industry.In recent years, {} has continued to expand its product offerings and capabilities, staying ahead of the curve in slip ring technology. By investing in state-of-the-art equipment and resources, the company has been able to meet the growing demand for anchor slip rings while maintaining the highest levels of quality and performance.Looking ahead, {} is poised for further growth and success in the slip ring market, with an ongoing commitment to innovation, customer satisfaction, and technological advancement. As industries continue to evolve and demand for high-quality slip rings increases, {} is well-positioned to meet the needs of its customers and solidify its position as a leader in the industry.In conclusion, anchor slip rings are vital components in a wide range of industrial applications, and {} stands out as a trusted provider of high-performance slip ring solutions. With a focus on quality, innovation, and customer satisfaction, the company has established itself as a leader in the industry, and is poised for continued success and growth in the years to come.

High Power RF Rotary Joints: What You Need to Know

High Power Rf Rotary Joints – A Breakthrough in Rotary Joint TechnologyIn the world of telecommunications and radio frequency (RF) technology, the need for high-power RF rotary joints that can reliably transfer signals and power while rotating continuously has been a long-standing challenge. However, with the recent introduction of High Power RF Rotary Joints by {}, this challenge has been overcome with a breakthrough in rotary joint technology.{} has been at the forefront of developing cutting-edge RF technologies and solutions for various industries including aerospace, defense, telecommunications, and medical devices. With a strong focus on research and development, the company has always strived to push the boundaries of what is possible in the field of RF technology.The High Power RF Rotary Joints developed by {} are a testament to the company's innovative spirit and commitment to addressing the evolving needs of the industry. These rotary joints are engineered to handle high levels of power and provide continuous rotary motion without sacrificing signal integrity. This is particularly crucial in applications where the transmission of high-power RF signals is essential, such as in radar systems, satellite communication, and high-power RF transmitters.One of the key features of the High Power RF Rotary Joints is their ability to handle power levels of up to [insert power level] Watts, making them suitable for high-power RF applications. This level of power handling is a significant advancement in rotary joint technology and opens up new possibilities for high-power RF transmission in various industries.Additionally, the High Power RF Rotary Joints from {} are designed to operate over a wide frequency range, ensuring that they can accommodate the diverse frequency requirements of different applications. This flexibility in frequency handling makes these rotary joints highly versatile and adaptable to a range of RF systems.Another notable aspect of the High Power RF Rotary Joints is their reliability and durability. {} has employed state-of-the-art materials and precision engineering to ensure that these rotary joints can withstand the rigors of continuous rotation and high-power transmission. As a result, the rotary joints offer a long service life and consistent performance, even in demanding operating conditions.The development and introduction of the High Power RF Rotary Joints underscore {}'s commitment to staying at the forefront of RF technology innovation. By addressing the longstanding need for high-power rotary joints, the company is not only catering to the current demands of the industry but also paving the way for future advancements in high-power RF transmission.Furthermore, {}'s expertise in customizing RF solutions allows the company to tailor the High Power RF Rotary Joints to specific customer requirements. This customization capability ensures that the rotary joints can seamlessly integrate into a wide range of RF systems, providing a bespoke solution for each application.In conclusion, the introduction of the High Power RF Rotary Joints by {} represents a significant milestone in rotary joint technology. With their high-power handling capabilities, wide frequency range, and reliability, these rotary joints are poised to make a substantial impact on the field of high-power RF transmission. As the industry continues to evolve, {} is at the forefront, driving innovation and shaping the future of RF technology.

Enhance Excavator Performance with a Reliable Rotary Union

Excavator Rotary Union Enhances Performance in Construction IndustryInnovation in the construction industry has always played a vital role in improving efficiency and productivity. As excavators continue to pave the way for groundbreaking developments in the sector, one component that has been constantly evolving is the excavator rotary union. By effectively joining hydraulic and electrical systems, this essential device has become instrumental in optimising the performance of excavators.Rotary unions, known by various names including swivels or rotary joints, are dynamic components that allow for the transfer of fluid or gas from a stationary input to a rotating output in machinery. In the context of excavators, rotary unions play a pivotal role in connecting the hydraulic circuits responsible for operating the machinery, and ensure a seamless power supply during rotary motion. The ability to transmit hydraulic fluid and electrical signals under such conditions significantly enhances the performance, reliability, and versatility of excavators.One prime example of an excavator rotary union that has revolutionised the industry is the product developed by {Company Name}. With their extensive experience and dedication to delivering high-quality components, {Company Name} has emerged as a leading manufacturer in this industry. While we will refrain from mentioning their brand name to avoid any promotional context, it is essential to highlight the exceptional features that set their product apart.The excavator rotary union developed by {Company Name} boasts several impressive characteristics. Firstly, the rotary union is designed with advanced sealing technologies to prevent fluid leakage, ensuring consistent and reliable performance. This level of reliability is critical in industries where any downtime can result in significant financial losses.Secondly, the excavator rotary union incorporates wear-resistant components that help prolong its service life even under harsh operating conditions. The demanding nature of construction sites necessitates durability, and {Company Name} has addressed this need by prioritising the longevity of their product.Furthermore, {Company Name}'s rotary union for excavators offers exceptional signal transmission capabilities. This means that electrical signals can be reliably transmitted between stationary and rotating parts of the excavator, enabling the seamless operation of additional attachments and auxiliary devices. This feature expands the range of potential applications for excavators and allows for greater adaptability on construction sites.Moreover, the excavator rotary union developed by {Company Name} has undergone extensive testing and quality assurance measures to ensure compliance with industry standards. By meeting stringent performance criteria, the product provides peace of mind to construction companies, knowing they can rely on the equipment to perform optimally in any working conditions.With advancements in technology, the latest excavator rotary unions feature compact designs that fit seamlessly into modern hydraulic systems. {Company Name}'s product, for instance, has a streamlined structure that minimises weight and space requirements. This not only enhances the overall efficiency of the excavator but also provides additional room for other essential components.In conclusion, the excavator rotary union has progressed significantly in recent years, and {Company Name} has been at the forefront of this evolution. Their commitment to innovation and superior performance has resulted in a product that meets the demanding requirements of the construction industry. By ensuring reliable fluid and electrical transmission, remarkable durability, and compliance with industry standards, {Company Name} has positioned itself as a reliable partner in the quest for greater efficiency, productivity, and versatility in the field of excavators.

Choosing Between Standard and Custom Slip Rings and Inductive, Capacitive, and Wetted Mercury Variations: Exploring Options for Advanced Components

As technological advancements continue to grow, machines become more complex, requiring advanced components to keep them functioning smoothly. Among the crucial parts in these machines are slip rings. They play a critical role in transmitting power and electrical signals from the stationary to the rotating components of a machine.Slip-rings come in different varieties, including inductive, capacitive, and wetted mercury variations. The advanced components range in bore sizes from half an inch to many feet in diameter, designed for medical imaging machines, livestock service systems, and other applications. However, the variations go beyond mere scale, and this poses a challenge for OEMs and design engineers, who must choose between standard and custom options and other critical factors to ensure the optimal slip-ring performance.Custom Slip Ring DesignOne of the factors that OEMs and design engineers consider when choosing between standard and custom slip rings is design flexibility. Custom slip ring design opens up limitless possibilities for machine designers, enabling them to tailor the slip rings to their specific requirements. Such flexibility allows for greater precision and control while saving on space, leading to a properly functioning system. It also eliminates the need for modifications after installation, making the final product more efficient.The design flexibility offered by custom slip rings provides OEMs and design engineers with a competitive advantage. With the ability to create customized slip rings built to precise specifications, they can offer their customers a unique solution, satisfying their specific needs and preferences.Reliability and PerformanceAnother critical factor when choosing between standard and custom slip rings is reliability and performance. The standard slip-ring options often lack the specialized features that different industries may require, leading to suboptimal performance. Custom slip rings ensure that all the elements required for optimal performance are included in the design, leading to a reliable, long-lasting, and efficient machine. This includes features such as high-temperature capabilities, corrosion resistance, and vibration absorption.The ability to customize slip rings also creates the opportunity for customized testing and validation processes. This ensures that the slip ring meets the specific application requirements and performs flawlessly without breakdowns and component failure.Cost ConsiderationsWhen choosing between standard and custom slip rings, cost considerations play a significant role. While customization offers the advantage of precision and optimal performance, it may be more expensive than off-the-shelf designs. Factors that affect custom slip ring cost include the design complexity, the materials used, production process, testing procedures, and validation.However, the cost of custom slip rings should not be a significant concern when considering the advantages that it can offer. Customization often results in increased production efficiency and decreased downtime, which ultimately lowers the operational costs of the machine in the long run.In conclusion, while choosing between standard and custom slip rings, OEMs and design engineers should consider several factors, including design flexibility, reliability, performance, and cost. Custom slip rings offer the advantage of precision and control, leading to greater efficiency, fewer modifications, and lower operation costs. Custom slip rings design is the perfect solution for those looking to create machines with specialized features that deliver optimal performance.

Benefits of Through Bore Slip Rings in Industrial Applications

Through Bore Slip Ring Market Growth, Trends, and Forecasts (2021 - 2026)The global Through Bore Slip Ring market is expected to grow at a CAGR of over 5% during the forecast period (2021-2026). The through bore slip ring, also known as a rotary electrical interface, is used to transfer power, electrical signals, and data from a stationary to a rotating structure. This technology has a wide range of applications, including in wind turbines, packaging equipment, industrial machinery, and medical equipment.The increasing demand for automation and robotics in various industries is one of the key factors driving the growth of the through bore slip ring market. With the rise of Industry 4.0, there is a growing need for seamless connectivity between stationary and rotating components in manufacturing processes. Through bore slip rings facilitate this connectivity, enabling the transfer of power and signals without the need for cables or wires.Additionally, the increasing adoption of renewable energy sources such as wind and solar power is expected to drive the demand for through bore slip rings. These slip rings are used in wind turbines to transfer power and data from the stationary base to the rotating blades, ensuring efficient and reliable operation.Furthermore, technological advancements in through bore slip ring designs are leading to the development of high-performance, compact, and lightweight solutions. These advanced slip rings offer improved reliability, longer service life, and enhanced capabilities to transfer power and signals in demanding industrial environments.Based in (Company Location), (Company Name) is a leading manufacturer of through bore slip rings, offering a wide range of standard and custom solutions for various applications. With over (number) years of experience in the industry, (Company Name) has established itself as a trusted supplier of high-quality slip rings to customers around the world.The company's through bore slip rings are designed to meet the rigorous demands of modern industrial and commercial applications. (Company Name) utilizes state-of-the-art manufacturing processes and quality control measures to ensure that its slip rings meet international standards for performance and reliability. The company's team of experienced engineers and technical staff work closely with customers to develop custom solutions that meet their specific requirements.In addition to standard through bore slip rings, (Company Name) also offers a range of accessories and services to support its customers. This includes slip ring assemblies, mounting brackets, and technical support for installation and maintenance. The company's commitment to providing comprehensive solutions sets it apart from competitors in the market.As a global supplier, (Company Name) has a strong presence in key regions such as North America, Europe, and Asia Pacific. The company has established a robust distribution network and partnerships with leading industrial and automation companies to ensure the availability of its products worldwide. This extensive reach allows (Company Name) to effectively serve a diverse customer base across different industries.Looking ahead, (Company Name) is focused on further enhancing its product portfolio with advanced through bore slip ring technologies. The company is investing in research and development to address the evolving needs of its customers and stay ahead of market trends. By leveraging its expertise and capabilities, (Company Name) aims to continue driving innovation and delivering value to its customers in the through bore slip ring market.In conclusion, the global through bore slip ring market is poised for significant growth driven by the increasing demand for automation, renewable energy, and advanced industrial machinery. (Company Name) is well-positioned to capitalize on these opportunities with its high-quality products, technical expertise, and global presence. As the market continues to evolve, (Company Name) remains committed to providing reliable and innovative solutions to meet the evolving needs of its customers.

Enhancing Robotic Systems with Slip Rings: A Key Component for Efficient Performance

Slip Ring technology has been widely used in various industries, especially in precision instruments and equipment such as robotics. Robotics, which is rapidly becoming one of the fastest growing industries in the world, requires high-precision motion control. Slip rings play a significant role in achieving such motion control in robotic devices.Slip rings are electrical connectors that can transmit electrical power or signal from a stationary object to rotating parts. In robotics, slip rings are used to transfer power and signal between the body and the rotating part of the robot. In other words, slip rings can provide a continuous power supply and data transfer between two components that rotate in opposite directions.The slip ring technology enhances the precision and accuracy of robotic movements that require a high degree of rotation, such as robotic arms and grippers. In addition, they can provide valuable feedback like position data, allowing better control and smoother operation of robotic devices.One of the best examples of the application of slip ring technology in robotics is in the medical industry. Robots have been used for many years in surgeries due to their high level of precision and control, reducing the risks that may be associated with human error. Medical robots, especially surgical robots, require enough rotations and precision levels for successful procedures. Slip ring technology ensures that the robots run smoothly and continuously, transmitting power and signals without interruption or interference.Slip rings enable the robotics industry to achieve greater heights with the development of robots that can take over hazardous tasks and operate in adverse conditions. For instance, exploration robots that work in hostile areas such as deep sea floors, where environmental conditions such as temperature and pressure are extreme, rely on slip ring technology as a reliable method of transmitting power and data.In the same manner, slip ring technology is employed in space exploration robots that operate under extreme temperatures and harsh atmospheric conditions. Successful space missions like the Mars Exploration Rover employed slip ring technology, allowing the robot to traverse the sandy environment and collect valuable data that scientists are still analyzing.As a result of the versatility of slip rings, they find application in various industries, including military, automotive, and heavy machinery, among others. Slip ring technology is becoming increasingly important with the growing demand for high-precision motion control-enabled by the evolving robotics industry.With the increasing demand for slip ring technology, foreign companies like [Brand Name] have made it their mandate to provide high-quality slip rings that offer reliable service in various sectors of the industry. They have over the years invested in state-of-the-art technology used in the production of slip rings, including robotic assembly systems, high-speed automated winding machines, and advanced computerized testing equipment. [Brand Name] also employs experienced engineers and technicians who work together to produce slip rings that meet international quality standards.Founded in the early 1990s, [Brand Name] has over 30 years of experience in manufacturing slip rings and has been at the forefront of the development of slip ring technology. They are a world-class manufacturer of slip rings, offering a wide range of slip rings that cater to different industries' power and data transfer requirements. They have a broad portfolio of slip rings including miniature slip rings, fiber optic slip rings, high-frequency slip rings, and hybrid slip rings among others.Over the years, [Brand name] has established long-term relationships with both local and international companies, with their representative offices and facilities strategically located in different countries across the world. They have an extensive network of distributors and clients who trust them to supply quality slip rings that conform to international standards and guidelines.In conclusion, the importance of slip rings in robotics and other industries that rely on precision motion control cannot be underestimated. With the continually evolving robotics industry, the demand for quality slip rings has increased, and companies such as [Brand Name] have invested in state-of-the-art technology, hiring experienced engineers and technicians to ensure their production meets international quality standards. Slip ring technology remains a game-changer in the robotics industry and other sectors that need reliable power and data transfer mechanisms, enabling robots to perform tasks that were once impossible.